Audi A4: Exhaust System, Emissions Controls

Exhaust Pipes/Mufflers

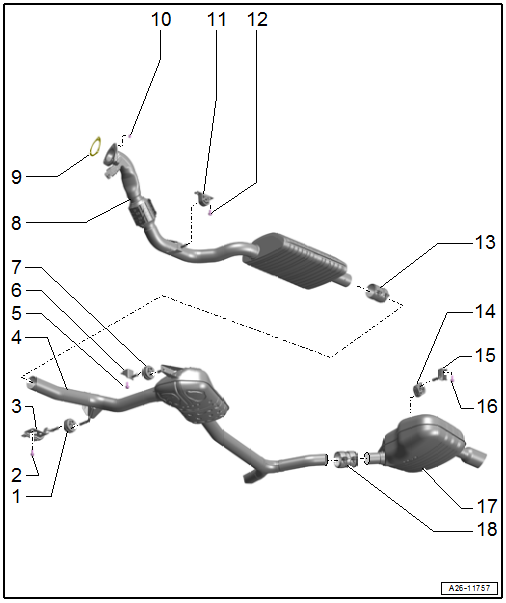

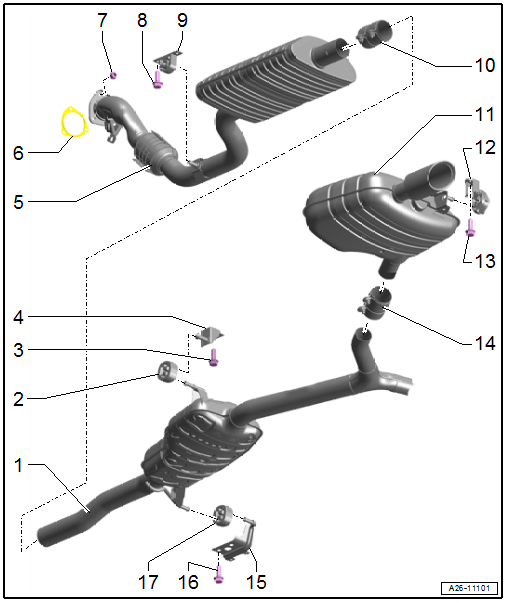

Overview - Muffler

Overview - Muffler, FWD Vehicle

1 - Retaining Loop

- Replace if damaged

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

2 - Bolt

- 23 Nm

3 - Bracket

4 - Center Muffler

- Original equipment as one unit with the rear muffler. If a repair is required replace each separately

- Separating point. Refer to → Chapter "Exhaust Pipes/Mufflers, Disconnecting".

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

5 - Bolt

- 23 Nm

6 - Bracket

7 - Retaining Loop

- Replace if damaged

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

8 - Front Muffler

- With a coupling

Caution

Caution

Risk of damaging the coupling.

- Coupling must not be bent more than 10º.

- Do not load the coupling on the cable.

- Do not damage the wire mesh on the coupling.

- Removing and installing. Refer to → Chapter "Front Muffler, Removing and Installing".

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

9 - Seal

- Replace after removing

10 - Nut

- 23 Nm

11 - Mount

- Equipped on some models

- Replace if damaged

- Check the pretension. Refer to → Chapter "Exhaust System, Installing without Tension".

12 - Bolt

- 23 Nm

13 - Front Clamping Sleeve

- Before tightening, align the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

- Installation position. Refer to → Fig. "Front Clamping Sleeve - Installation Position".

- Tighten the threaded connections equally to 23 Nm.

14 - Retaining Loop

- Replace if damaged

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

15 - Bracket

16 - Bolt

- 23 Nm

17 - Rear Muffler

- Original equipment one unit with the center muffler. If a repair is required replace each separately

- Separating point. Refer to → Chapter "Exhaust Pipes/Mufflers, Disconnecting".

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

18 - Rear Clamping Sleeve

- Before tightening, align the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

- Installation position. Refer to → Fig. "Rear Clamping Sleeve - Installation Position".

- Tighten the threaded connections equally to 23 Nm.

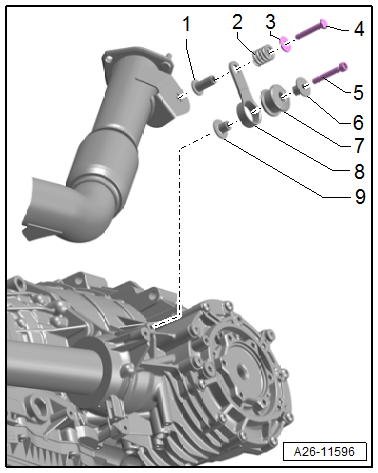

Individual Mounting Components for Front Muffler

1 - Spacer Sleeve

2 - Pressure Spring

3 - Washer

4 - Bolt - 23 Nm

5 - Bolt - 23 Nm

6 - Spacer Sleeve

7 - Buffer

8 - Tab

9 - Spacer Sleeve

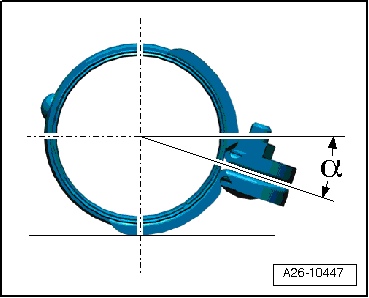

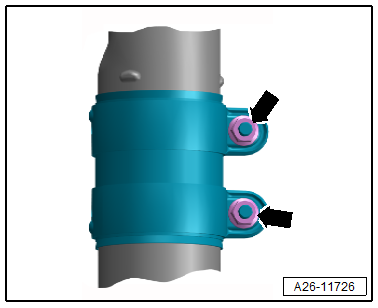

Front Clamping Sleeve - Installation Position

- Install the clamping sleeve in the position shown.

- Angle -α- = approximately 20º.

- The threaded connections are to the right.

- Nuts downward.

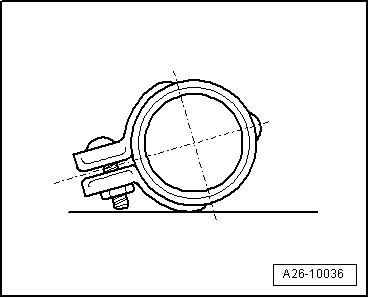

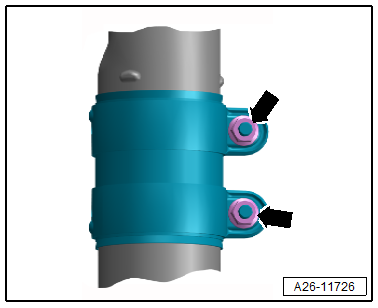

Rear Clamping Sleeve - Installation Position

- Install the clamping sleeve in the position shown.

- Threaded connections are to the left.

- Nuts downward.

- Bolt ends must not protrude over the lower edge of the clamping sleeve.

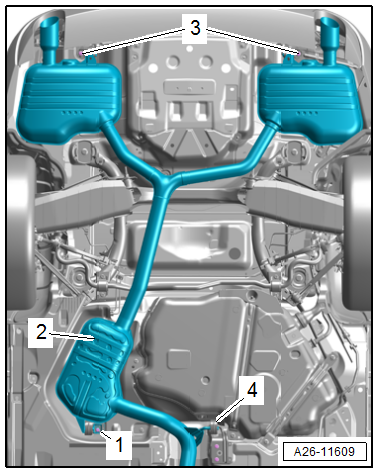

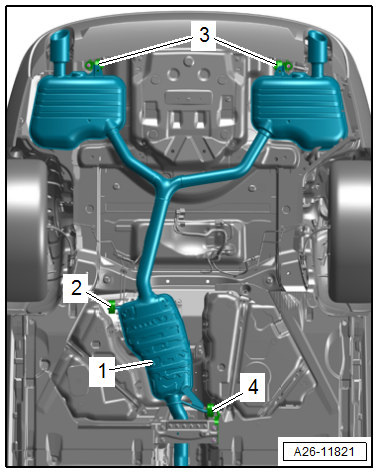

Overview - Muffler, AWD Vehicles

1 - Center Muffler

- Original equipment as one unit with rear mufflers. If a repair is required replace each separately

- Separating point. Refer to → Chapter "Exhaust Pipes/Mufflers, Disconnecting".

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

2 - Retaining Loop

- Replace if damaged

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

3 - Bolt

- 23 Nm

4 - Bracket

5 - Front Muffler

- With a coupling

Caution

Caution

Risk of damaging the coupling.

- Coupling must not be bent more than 10º.

- Do not load the coupling on the cable.

- Do not damage the wire mesh on the coupling.

- Removing and installing. Refer to → Chapter "Front Muffler, Removing and Installing".

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

6 - Seal

- Replace after removing

7 - Nut

- 23 Nm

8 - Bolt

- 23 Nm

9 - Mount

- Replace if damaged

- Check the pretension. Refer to → Chapter "Exhaust System, Installing without Tension".

10 - Front Clamping Sleeve

- Before tightening, align the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

- Installation position. Refer to → Fig. "Front Clamping Sleeve - Installation Position".

- Tighten the threaded connections equally to 23 Nm.

11 - Rear Muffler

- Original equipment one unit with the center muffler. If a repair is required replace each separately

- Separating point. Refer to → Chapter "Exhaust Pipes/Mufflers, Disconnecting".

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

12 - Mount

- Replace if damaged

- Check the pretension. Refer to → Chapter "Exhaust System, Installing without Tension".

13 - Bolt

- 23 Nm

14 - Rear Clamping Sleeve

- Before tightening, align the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

- Installation position. Refer to → Fig. "Rear Clamping Sleeve - Installation Position".

- Tighten the threaded connections equally to 23 Nm.

15 - Bracket

16 - Bolt

- 23 Nm

17 - Retaining Loop

- Replace if damaged

- Exhaust system, installing without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

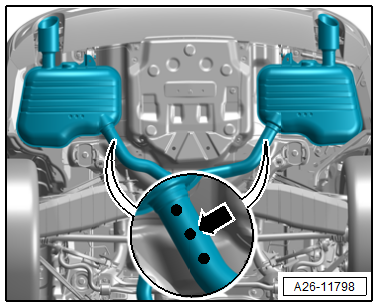

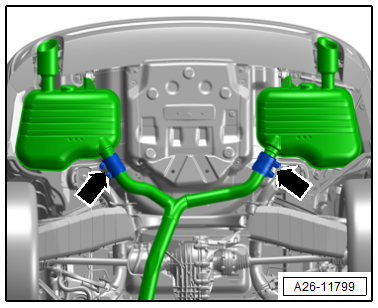

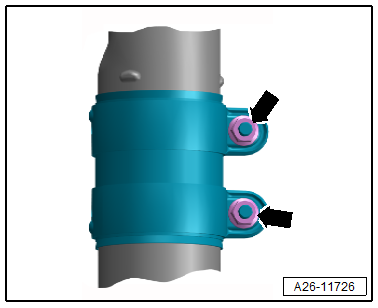

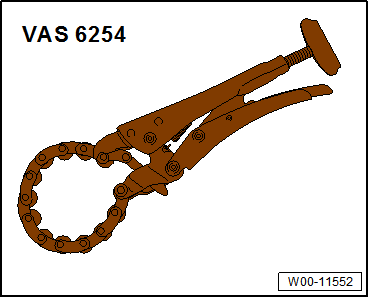

Exhaust Pipes/Mufflers, Disconnecting

Special tools and workshop equipment required

- Chain Pipe Cutter -VAS6254-

- A separating point has been provided in the connecting pipe for individual replacement of the center or rear muffler.

- The separating point is marked by an indentation around the circumference of the exhaust pipe.

Procedure

- Separate the exhaust pipes at a right angle at the notch -arrow- using a -VAS6254-.

- When installing, position the clamping sleeves -arrows- on the center of the separation cut.

- Install the clamping sleeves. Refer to → Fig. "Rear Clamping Sleeve - Installation Position".

- Install the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

Tightening Specifications

- Refer to → Chapter "Overview - Muffler"

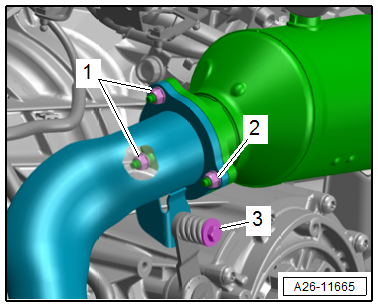

Front Muffler, Removing and Installing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Mandatory Replacement Parts

- Seal - Front Muffler

Removing

- Remove the engine cover. Refer to → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.10; Engine Cover; Engine Cover, Removing and Installing.

- Remove the nuts -1- from the front muffler accessible from the top.

- Remove the rear noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

- Remove the nut -2- and bolt -3- for the front muffler.

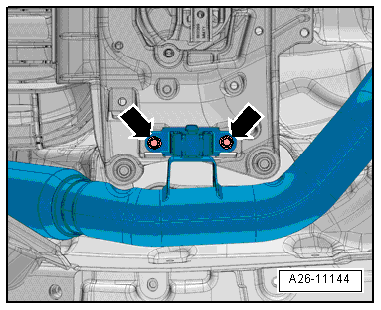

- Remove the front muffler bolts -arrows-.

- Loosen the clamping sleeve -arrows- and push toward the rear.

Caution

Caution

Risk of damaging the coupling.

- Coupling must not be bent more than 10º.

- Do not load the coupling on the cable.

- Do not damage the wire mesh on the coupling.

- Remove the front muffler.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace seals and self-locking nuts after disassembly.

- Install the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

- Install the engine cover. Refer to → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.10; Engine Cover; Engine Cover, Removing and Installing.

Tightening Specifications

- Refer to → Chapter "Overview - Muffler"

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

Muffler, Removing and Installing

Removing

- Equipped on some models: remove the left and right diagonal brace. Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Underbody Trim Panels, Removing and Installing.

- Loosen the clamping sleeve -arrows- and push toward the rear.

Caution

Caution

Risk of damaging the couplings in the front muffler.

Do not bend couplings in front muffler more than 10º.

- Slightly lower the front muffler and remove the clamping sleeve.

- Tie up the front muffler.

FWD Vehicle

WARNING

WARNING

Risk of accident due to the weight of the muffler.

A second technician is needed to remove the rear muffler.

- Disengage the mounting -4- from the exhaust system.

- Remove the bolts -1 and 3- and remove the muffler -2-.

AWD Vehicles

WARNING

WARNING

Risk of accident due to the weight of the muffler.

A second technician is needed to remove the rear muffler.

- Disengage the mounting -2 and 4- from the exhaust system.

- Remove the bolts -3- and remove the muffler -1-.

Installing

Install in reverse order of removal and note the following:

- Install the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

Tightening Specifications

- Refer to → Chapter "Overview - Muffler"

- Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Component Location Overview - Trim Panels.

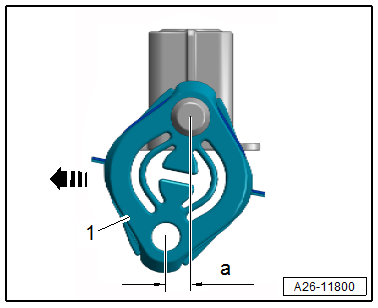

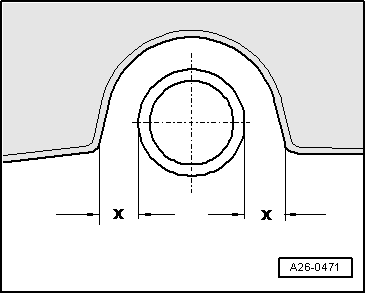

Exhaust System, Installing without Tension

Procedure

- Align the exhaust system when cold.

- Loosen the front clamping sleeve -arrows-.

- Push the exhaust system far enough forward -arrow- until the pretension on the retaining loop -1- at the exhaust pipe is -a- = 6 to 10 mm.

- Position the front clamping sleeve (refer to → Fig. "Front Clamping Sleeve - Installation Position") and tighten the threaded connections evenly.

- Check the distance of left and right tail pipes to bumper:

- Dimension -x- left = dimension -x- right.

Tightening Specifications

- Refer to → Chapter "Overview - Muffler"

Exhaust System, Checking for Leaks

All procedures are described under: → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.26; Exhaust Pipes/Mufflers; Exhaust System, Checking for Leaks.

Emissions Control System

All procedures and components are described under: → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.26; Emissions Control System.

Special Tools

Special tools and workshop equipment required

- Chain Pipe Cutter -VAS6254-

Ignition/Glow Plug System

Ignition System

All procedures and components are described under: → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.28; Ignition System.

Revision History

DRUCK NUMBER: A005A013621

.png)