Audi A4: Subframe, Lowering

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Tensioning Straps -T10038-

- Engine and Gearbox Jack -VAS6931-

- Locating Pins -T40327-

Procedure

Note

Note

During installation, all cable ties must be installed at the same location.

- Before starting the procedure, determine the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Secure the subframe. Refer to → Chapter "Subframe, Securing".

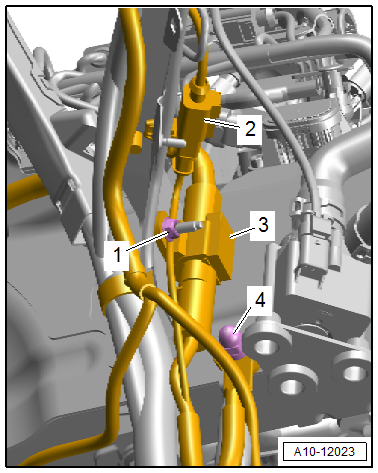

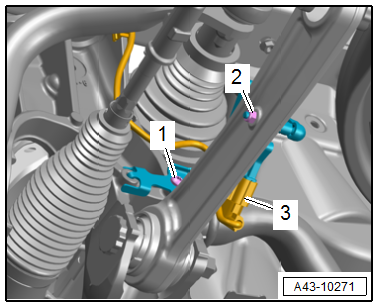

- Disconnect the connector -2- and free up the wire.

- Loosen the nut -1- several turns, and free up and disconnect the connector -3-.

- Remove the nut -4- and free up the ground wire.

- Free up the wires to the steering gear.

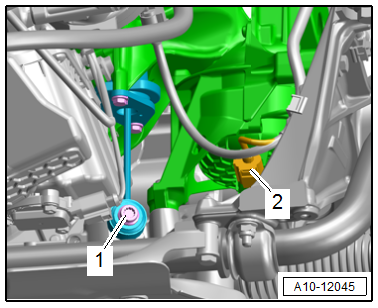

- Equipment versions with electro-hydraulic engine mount: Disconnect the left and right connector -2- for the electrohydraulic engine mount solenoid valve.

- Equipment versions with support bearing: remove the left and right bolt -1- for the support bearing.

Note

Note

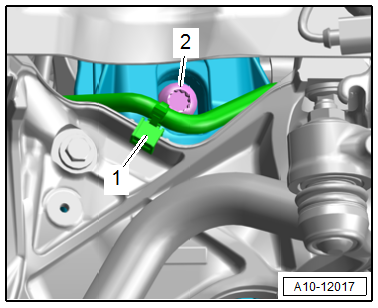

The illustration shows the installation position on a vehicle with a 2.0L TFSI engine.

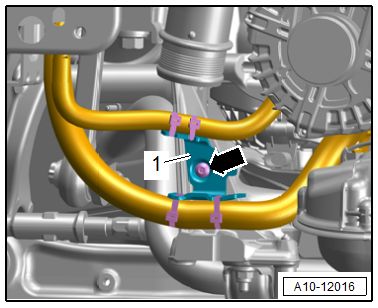

- Remove the bolt -arrow- and free up the bracket -1- with the wiring harness.

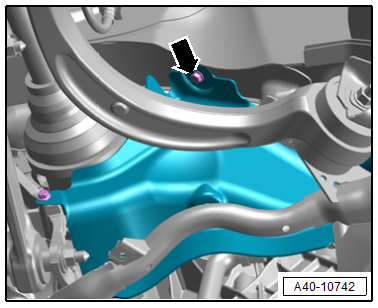

- Remove the left and right bolts -arrow- for the subframe shield.

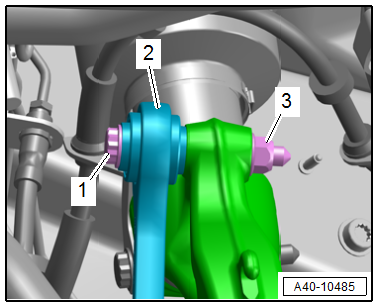

- Remove the left and right nut -3- and the bolt -1- for the coupling rod -2-.

- Remove the steering intermediate shaft from the steering gear and then push together. Refer to → Chapter "Steering Intermediate Shaft, Removing and Installing".

- Remove the left and right drive axle from the transmission. Refer to → Chapter "Drive Axle, Removing and Installing".

- Equipment versions with electronic damping: Disconnect the left and right connector -3- for the level control system sensor and free up the wire.

Note

Note

Ignore items -1 and 2-.

- Equipment versions with SCR system: Free up the SCR delivery line -1- on the subframe.

- Remove the left and right bolt -2- and lower the subframe with the -VAS6931-.

Note

Note

- Make sure there is enough clearance for the wires when lowering the subframe.

- If required for other procedures, tie up the subframe to the body with -T10038- and remove the -VAS6931-.

Installing

Install in reverse order of removal and note the following:

- Remove the -T40327-. Refer to → Chapter "Subframe, Securing".

- Install the steering intermediate shaft. Refer to → Chapter "Steering Intermediate Shaft, Removing and Installing".

Note

Note

Bonded rubber bushings have a limited range of rotation. Only tighten the threaded connections for the suspension when the vehicle is in curb weight position.

- Lift the wheel bearing in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring"

WARNING

WARNING

Risk of accident!

If the vehicle will be driving on the streets, all bolts and nuts must be tightened properly according to the guidelines.

- Connections and wire routing. Refer to → Wiring diagrams, Troubleshooting & Component locations.

Tightening Specifications

- Refer to → Chapter "Overview - Subframe"

- Refer to → Chapter "Overview - Drive Axle"

- Refer to → Body Exterior; Rep. Gr.63; Front Bumper Cover; Overview - Impact Member.

- Refer to → Chapter "Wheels and Tires"