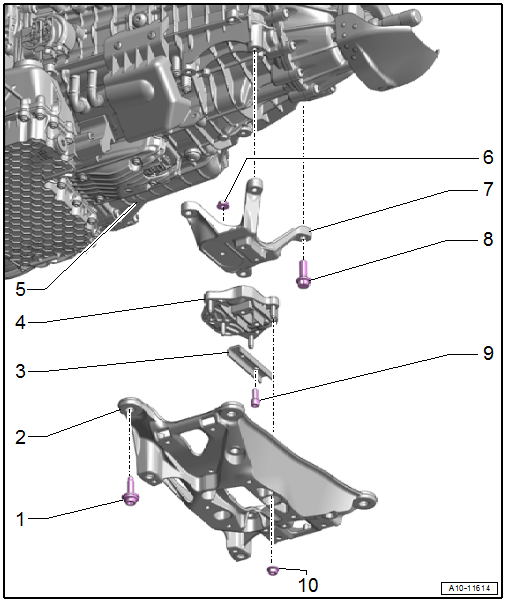

Audi A4: Subframe Mount

Overview - Subframe Mount

1 - Bolt

- 70 Nm for FWD vehicles (M10x40 10.9)

- 40 Nm +90º for AWD vehicles (M10x40 8.8)

2 - Tunnel Crossmember

- Removing and installing. Refer to → Chapter "Tunnel Crossmember, Removing and Installing".

3 - Stop

- For the transmission mount

4 - Transmission Mount

- Removing and installing. Refer to → Rep. Gr.10; Subframe Mount; Transmission Mount, Removing and Installing.

5 - Transmission

6 - Nut

- 20 Nm

7 - Transmission Support

- Removing and installing. Refer to → Rep. Gr.10; Subframe Mount; Transmission Mount, Removing and Installing.

8 - Bolt

- 40 Nm

9 - Bolt

- 20 Nm +90º

- Replace after removing

10 - Nut

- 20 Nm

Tunnel Crossmember, Removing and Installing

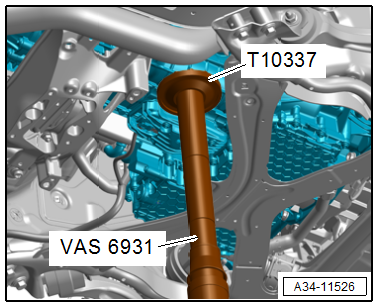

Special tools and workshop equipment required

- Engine and Gearbox Jack -VAS6931-

- Engine/Gearbox Jack - Gearbox Support -T10337-

Removing

- Remove the rear noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

- Place the Engine/Gearbox Jack - Gearbox Support -T10337- on the Engine and Gearbox Jack -VAS6931- and set it on the bottom of the transmission, as shown in the image.

- Raise the transmission slightly.

WARNING

WARNING

There is the risk of an accident.

The Engine and Gearbox Jack -VAS6931- may only be used during assembly and must not sit unsupervised under the vehicle.

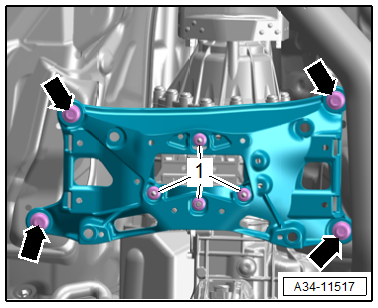

- Remove the bolts -arrows- and the nuts -1- and remove the tunnel crossmember.

Installing

Install in reverse order of removal.

Tightening Specifications

- Refer to → Chapter "Overview - Subframe Mount"

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.