Audi A4: Wheel Bearing Unit, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Mandatory Replacement Parts

- Bolt - Ball Joint to Wheel Bearing Housing

- Nut - Ball Joint to Control Arm

Removing

Caution

Caution

There is a risk of damaging or contaminating the wheel bearing.

Handling the wheel bearing.

- Loosen the connection between the drive axle and wheel hub. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

- Remove the brake rotor. Refer to → Brake System; Rep. Gr.46; Front Brakes; Brake Rotor, Removing and Installing.

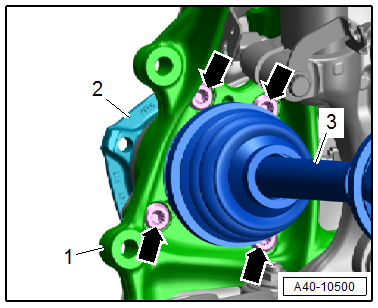

- Remove the bolts -arrows-.

- Remove the wheel hub -2- with the wheel bearing unit from the drive axle -3- and remove it from the wheel bearing housing -1-.

Installing

Install in reverse order of removal and note the following:

- Tighten the threaded connection between the drive axle and wheel hub. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

Tightening Specifications

- Refer to → Chapter "Overview - Wheel Bearing"

- Refer to → Chapter "Wheels and Tires"

Wheel Bearing Unit, Servicing

Special tools and workshop equipment required

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Multiple Use -VW412-

- Hydraulic Press - Bushing Assembly Tool Kit -T10230-

- Pneumatic Hydraulic Press -VAS6654-

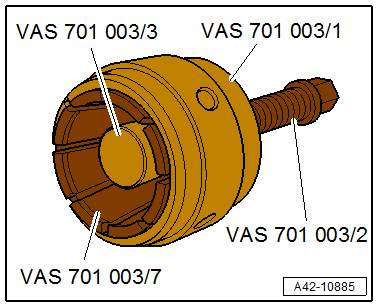

- Puller Set VAS701 003 -VAS70003-

- Hydraulic Press - Bushing Assembly Tool Kit - Sleeve -T10230/3-

- Hydraulic Press - Bushing Assembly Tool Kit - Thrust Piece -T10230/8-

- Puller Set VAS701 003 -VAS701003-

- Puller Set - Clamping Sleeve -VAS701003/1-

- Puller Set - Threaded Spindle -VAS701003/2-

- Puller Set - Thrust Piece -VAS701003/3-

- Puller Set - Clamping Handle -VAS70003/4-

- Puller Set - Special Ring Spanner AF36 -VAS701003/5-

- Puller Set - Clamping Pliers, Diameter 66-70 mm -VAS701003/7-

Procedure

- Wheel bearing unit is removed. Refer to → Chapter "Wheel Bearing Unit, Removing and Installing".

Wheel Hub, Removing from Wheel Bearing

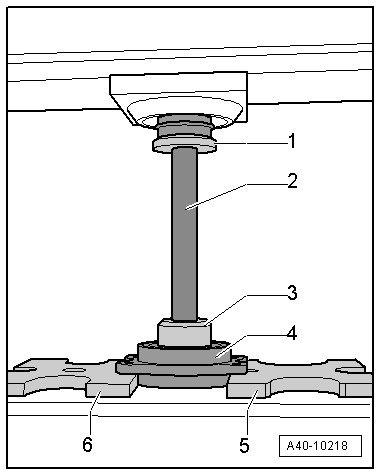

- Arrange the special tools as shown.

1 - -VW412-

2 - -T10230/3-

3 - -T10230/8-

4 - Wheel Bearing Unit

5 - -VW402-

6 - -VW401-

- Press the wheel hub out of the wheel bearing.

Bearing Inner Race, Removing from Wheel Hub

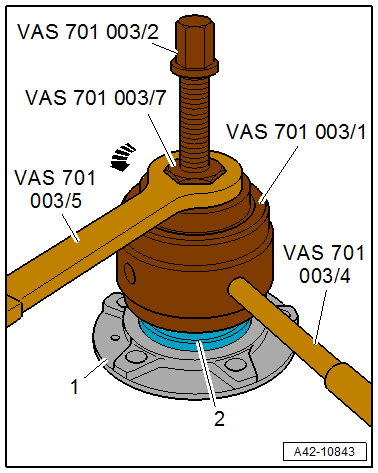

- Prepare the puller from the -VAS701003- as follows:

- Install the -VAS701003/1- on the -VAS701003/7-.

- Install the -VAS701003/2- in the adapter sleeve and attach the -VAS701003/3-.

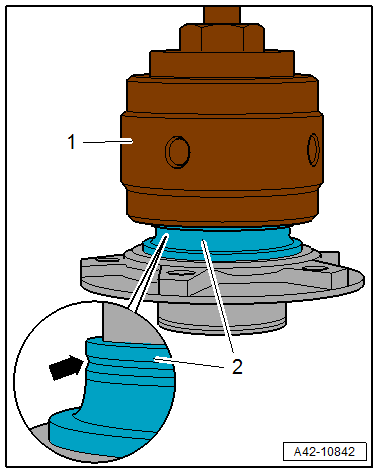

Bearing Inner Race Version 1

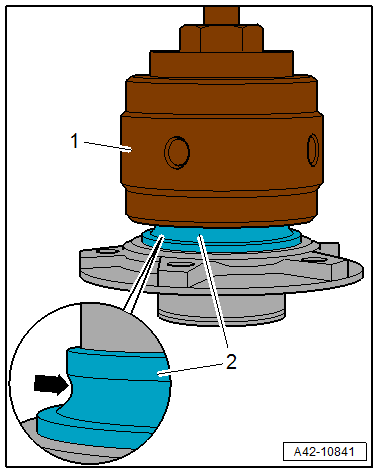

- Remove the ball-cage assembly from the bearing inner race -2-.

- Place the puller -1- as shown on the ball bearing race -arrow- of the bearing inner race.

Bearing Inner Race Version 2

- Place the puller -1- on the groove -arrow- of the bearing inner race -2-.

Continuation for All Versions

- Clamp the puller on the bearing inner race -2- by turning the -VAS701003/7- with the -VAS701003/5- in the direction of the -arrow- and counterhold the -VAS701 003/1- with the -VAS70003/4-.

- Remove the bearing inner race with the - VAS701003/2- from the wheel hub -1-.

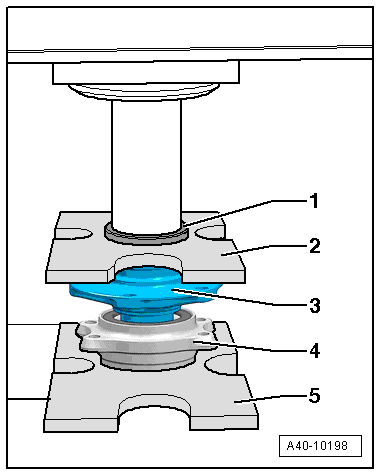

Wheel Hub, Pressing in Wheel Bearing

Handling the wheel bearing. Refer to → Fig. "Wheel Bearing, Handling".

- Arrange the special tools as shown.

1 - -VW412-

2 - -VW402-

3 - Wheel Hub

4 - Wheel Bearing

5 - -VW401-

- The reworked surface of the wheel bearing outer race faces down.

Caution

Caution

There is a risk of damaging or contaminating the wheel bearing.

When setting down or pressing in, make sure there is no dirt or contaminants between the -VW401- and the wheel bearing.

- Press the wheel hub into the wheel bearing.

- Install the wheel bearing unit. Refer to → Chapter "Wheel Bearing Unit, Removing and Installing".