Audi A4: Clamp on Triple Roller Joint and Outer Joint, Tensioning

Audi A4 (B9) 2016-2026 Service Manual / Chassis / Front Suspension / Drive Axle / Clamp on Triple Roller Joint and Outer Joint, Tensioning

Note

Note

Depending on the version of the clamp, use the following tools:

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Clamping Pliers -VAG1682A-

- Locking Pliers -VAS6199-

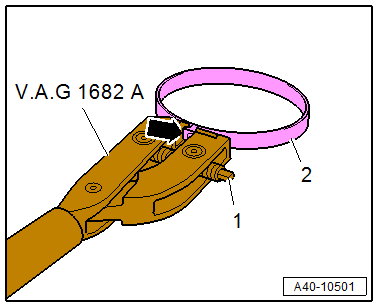

Tension the Stainless Steel Clamp using the -VAG1682A-.

- Attach the -VAG1682- as shown.

- The jaws on the pliers must be centered -arrow- on the clamp -2-.

Note

Note

- The spindle threads must turn easily. If necessary, coat with MoS2 lubricating grease.

- If difficult to tighten, for example because of dirty threads, the proper clamping force of the clamping sleeve will not be reached even when tightened to the specification.

- Tension the clamp by turning the spindle -1- with the torque wrench. Do not tilt the clamping pliers during this.

- Tightening specification: 20 Nm.

Tension the Clamp with Retaining Tabs using the -VAS6199-.

Note

Note

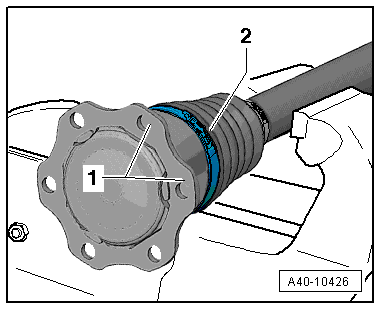

To better position the internal multi-point bolts when installing the drive axle, the clamp crimping ear -2- must be between the joint connecting flanges -1-.

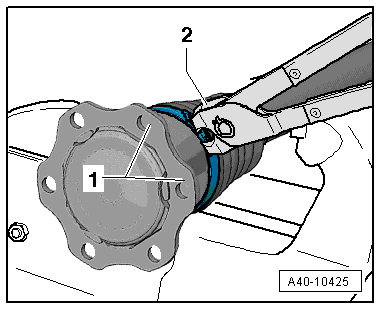

- Engage the clamp at the first catch by hand.

- Close the clamp using the -VAS6199--2-.

READ NEXT:

Special Tools

Special Tools

Special tools and workshop equipment required

Shock Absorber Set -T10001-

Tensioning Strap -T10038-

Tripod Joint Tool -T10065-

Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

SEE MORE:

Steering wheel

Steering wheel

General information

Make sure that:

The distance between your upper body and the

steering wheel is at least 10 inches (25 cm)

Your arms are bent slightly at the elbows

You have a sufficient view of the area around

the vehicle and you have a clear view of the instrument

cluster and head-up dis

General Information

General Information

Vehicles with a High Voltage System (Hybrid Vehicles)

Extremely Dangerous Due to High-Voltage

The high-voltage system is under high-voltage. Death or serious

bodily injury by electric shock.

- Individuals with electronic/medical life- and health sustaining

machines in or on their person canno

© 2019-2026 Copyright www.audia4b9.com