Audi A4: CV Joint, Servicing

Outer CV Joint, Removing

- Clamp the drive axle in a vise with protective covers.

- Open both clamps and remove the CV boot from the outer joint.

- Drive out the CV joint from the drive axle with a copper or brass mandrel -A- on the inner ring.

- Remove joint and CV boot.

Outer CV Joint, Installing

- The CV boot and the drive axle must be free of grease.

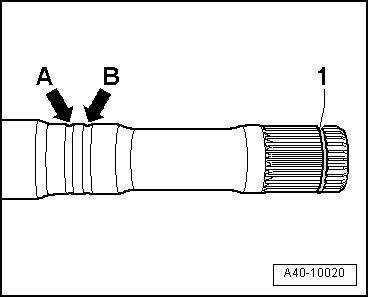

- Replace the circlip -1- after removing.

- Slide on the small clamp with the CV boot.

- Position the CV boot in the outer groove -arrow B-.

- Inner groove -arrow A- remains visible "identification groove" (for correct installation of CV boot).

- Add the specified quantity of grease to the inside of the joint.

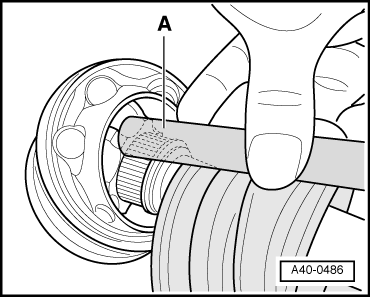

- Before installing the joint, the splines -arrow A- must be lightly coated with grease used in the joint.

- Insert the circlip into the groove on the shaft.

- Slide on the CV joint up to the circlip.

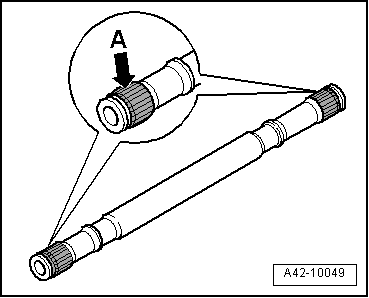

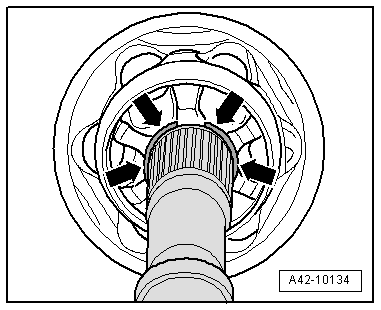

- Align the circlip at center with opening upward -arrows-.

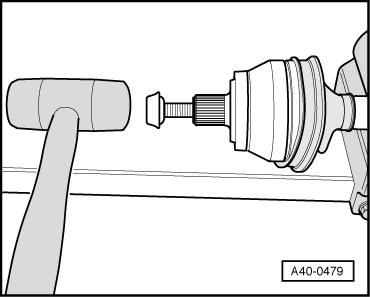

- Install the old drive axle screw in the joint.

- Drive joint onto the drive axle with a plastic mallet until the circlip engages.

- Add the specified quantity of the grease into the joint on the CV boot side.

- Slide the CV boot onto the joint.

- Bleed the CV boot.

- Make sure the CV boot is seated on the joint correctly.

- The CV boot must fit in the groove and on joint contour.

- Tension the clamps on the outer joint. Refer to → Chapter "Clamp on Triple Roller Joint and Outer Joint, Tensioning".