Audi A4: Outer CV Joint, Checking

It is necessary to disassemble the joint whenever replacing the grease or if the ball surfaces show wear or damage.

Disassembling

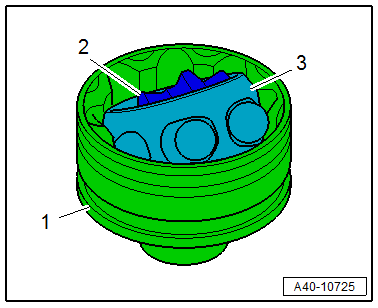

- Mark the position of the ball hub -2- to ball cage -3- and to housing -1- before disassembling, using an electric engraver or grindstone.

- Tilt the ball hub and ball cage.

- Remove the balls one after the other.

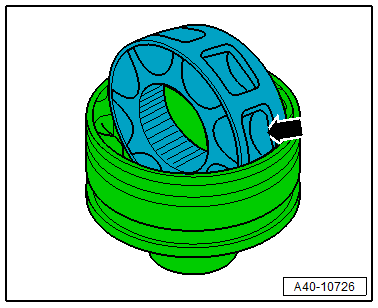

- Turn the cage, until two rectangular windows -arrow- rest on the joint housing.

- Lift out cage with hub.

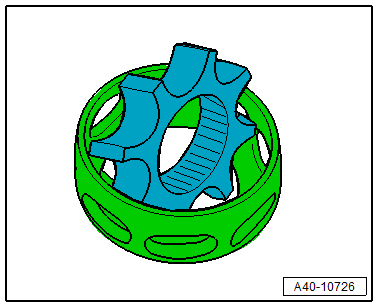

- Tilt the hub segment with shorter pins into rectangular window on the cage.

- Fold hub out from cage.

Checking

The balls for each joint belong to one tolerance group. Check the axle stub, hub, cage and balls for small depressions (pitting build-up) and chafing. Excessive backlash in the joint is noticeable by a thump during load alternations. The joint should be replaced in these cases. Flattening and running marks on the balls are no reason to replace a joint.

Assembling

- Insert cage with hub into joint body.

Note

Note

Cage must be inserted on the correct side.

- Press in the opposite facing balls one after the other, and the old ball hub position to the ball cage and to the joint housing must be replicated.

- Press the grease into the joint body.