Audi A4: Dual Clutch, Removing and Installing

Special tools and workshop equipment required

- Shop Crane -VAS6100-

- Puller - Input Shaft -T40050-

- Pressure Stand -T40099-

- Guide Pins - Gearbox -T40288-

- Engine Support Bridge - Additional Hooks (2 pc.) -10-222A/2-

Removing

- Secure the transmission on the Engine And Transmission Holder -VAS6095-. Refer to → Chapter "Securing on Engine and Transmission Holder".

- Remove the flywheel. Refer to → Chapter "Flywheel, Removing and Installing".

- Turn the transmission in the Engine and Gearbox Bracket -VAS6095A- so that it is vertical.

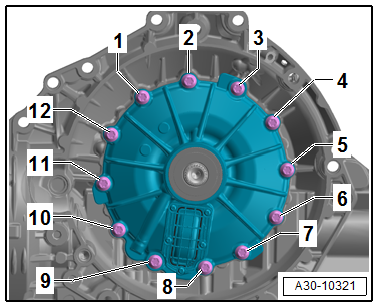

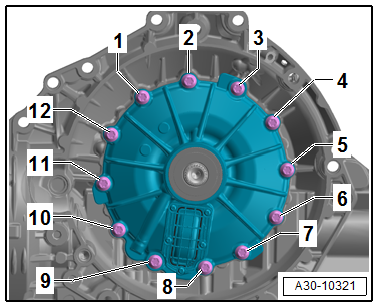

- Remove the bolts -1 to 12-.

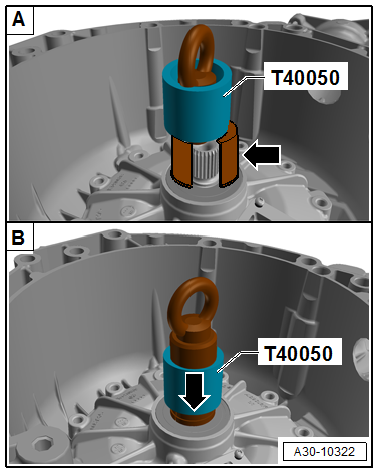

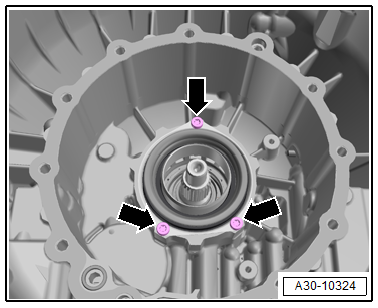

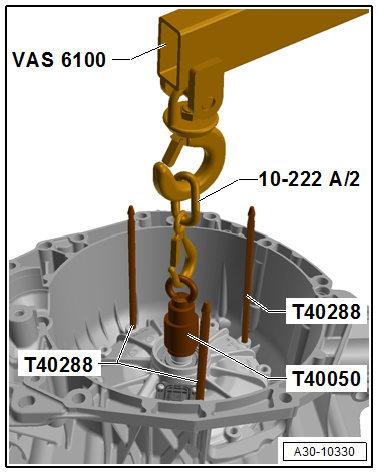

- Place the Puller - Input Shaft -T40050- on the input shaft clutch and lock -arrows-.

- Make sure the puller is secure on the input shaft.

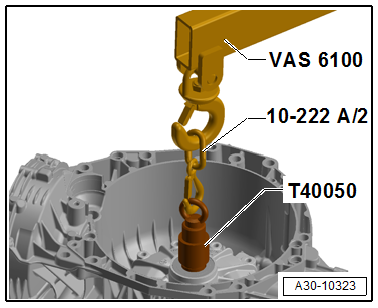

- Connect the Puller - Input Shaft -T40050- with the Engine Support Bridge - Additional Hooks (2 pc.) -10-222A/2- and engage in the Shop Crane -VAS6100-.

- Carefully remove the dual clutch out of the transmission housing.

Caution

Caution

When removing, the engaging bearing and both alignment sleeves can fall out of the transmission housing.

A damaged or dropped engaging bearing must be replaced.

Note

Note

- The dual clutch is extensively calibrated on the engaging bearing and slave cylinder.

- Calibrating with service equipment is not possible.

- A damaged engaging bearing or slave cylinder must for this reason always be replaced with a new clutch.

- A new clutch is always supplied with a calibrated engaging bearing and slave cylinder.

Caution

Caution

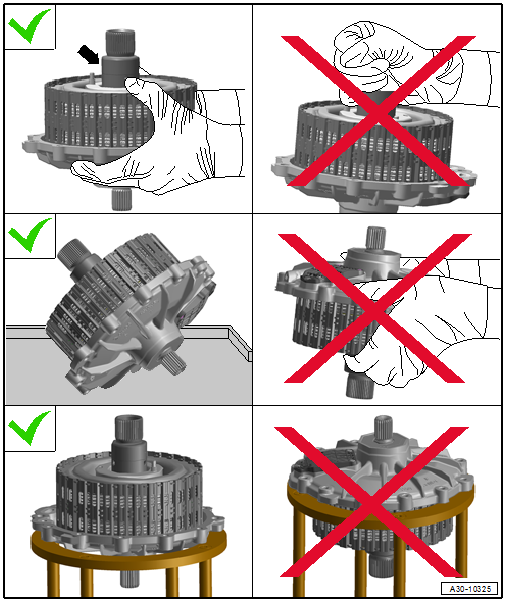

There is a risk of damaging the dual clutch from mishandling.

- The hub for "clutch 2" -arrow- is clipped in the inner disk support and can be loosed through mishandling of the clutch.

- Transport and position the clutch only as shown:

It can be checked by measuring the height dimension if the clutch is damaged.

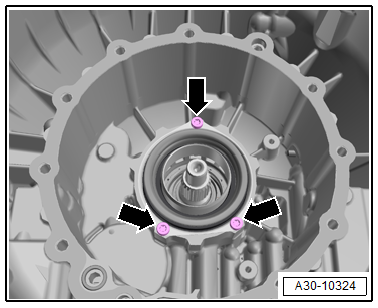

- Remove the three bolts -arrows- and remove the engaging bearing with the slave cylinder.

Note

Note

Depending on the version the three bolts -arrows- may not be present.

Installing

Note

Note

The double shaft seal for the input shaft must always be replaced! Refer to → Chapter "Input Shaft Double Shaft Seal, Replacing".

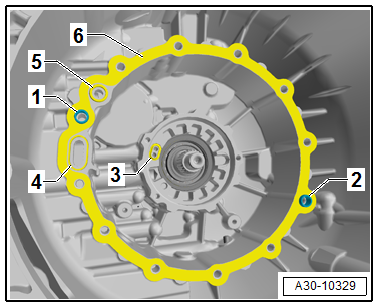

- Check if the sleeves -1 and 2- are installed.

- Coat the new seals -3, 4 and 5- with ATF and install.

- Insert the seal -6-.

Note

Note

Make sure no dirt can fall into the transmission while cleaning.

- Install the engaging bearing with the slave cylinder and tighten the three bolts -arrows- evenly.

Note

Note

Depending on the version the three bolts -arrows- may not be present.

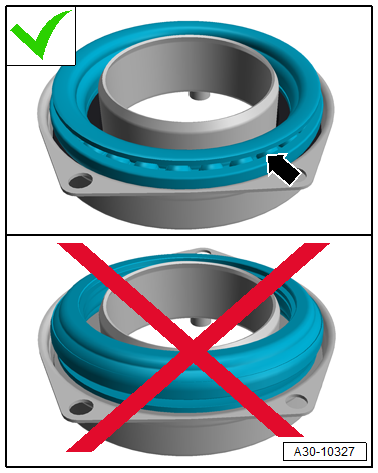

Note

Note

- Pay attention that the engaging bearing is installed correctly to the slave cylinder.

- The ball bearings are visible! -Arrow-

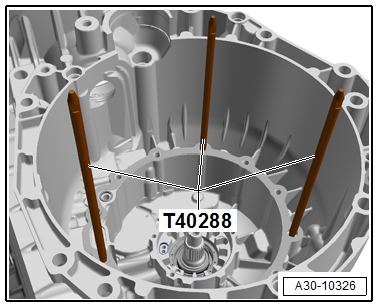

- Install the Guide Pins - Gearbox -T40288- in the threaded hole approximately 120º offset.

Check the Clutch Installation Height

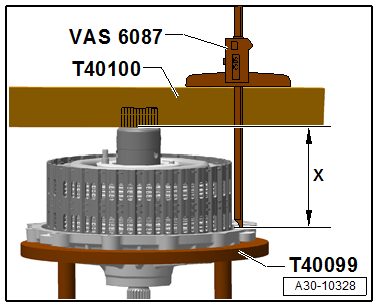

- Before installing the clutch the dimension -x- must be determined.

- To do so use the Ruler (2 pc.) -T40100- and Digital Depth Gauge -VAS6087- to determine the height of the clutch cover to the hub offset as shown.

The dimension -x- must be located within the tolerance of 98.91 to 99.61 mm.

Note

Note

If the dimension -x- is outside of the tolerance, the clutch must be replaced because it is damaged.

- Place the dual clutch as shown in the transmission housing.

- Tighten the bolts -1 to 12- for the clutch cover diagonally in steps. Tightening specification. Refer to → Chapter "Overview - Flywheel and Dual Clutch".

- Install the flywheel. Refer to → Chapter "Flywheel, Removing and Installing".

- After installing the transmission fill the ATF and transmission fluid. Refer to → Rep. Gr.34; ATF; ATF, Draining and Filling and → Rep. Gr.34; Transmission Fluid; Transmission Fluid, Draining and Filling

- After changing the dual clutch the clutch must be adapted. Refer to Vehicle Diagnostic Tester.

Procedure:

- Drivetrain

- 0CK Transmission

- 01 OBD-capable systems

- 02-Transmission electronics

- 02-Transmission electronics, functions

- 02-Basic Setting

- 04-Adapt clutch slip points