Audi A4: Hydraulic Pressure Sensor 1 -G545- and Hydraulic Pressure Sensor 2 -G546-, Removing and Installing

Note

Note

The Mechatronic remains installed.

WARNING

WARNING

The system is under pressure.

- The electronic ATF pump must be deactivated every time before opening the transmission, and the hydraulic pressure reservoir is drained.

- Refer to → Chapter "ATF Pump, Deactivating and Draining the Hydraulic Pump Reservoir".

- Remove the transmission fluid pan. Refer to → Chapter "Transmission Fluid Pan, Removing and Installing".

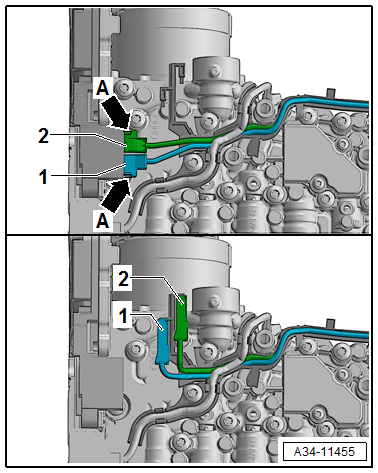

- Release the catches -arrows- from the connector for the Hydraulic Pressure Sensor 1 -G545--1- and Hydraulic Pressure Sensor 2 -G546--2- and disconnect from the Transmission Control Module -J217-.

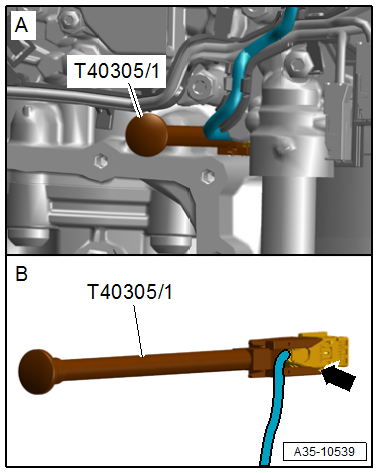

- Using the Assembly Tool -T40305- disconnect the connector for the Gear Position Distance Sensor 2 -G488--arrow- and remove it from the wiring guide.

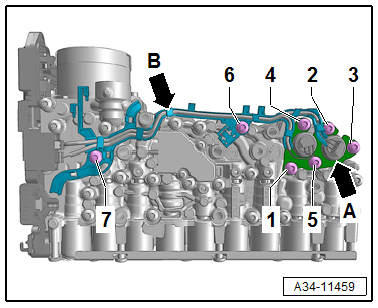

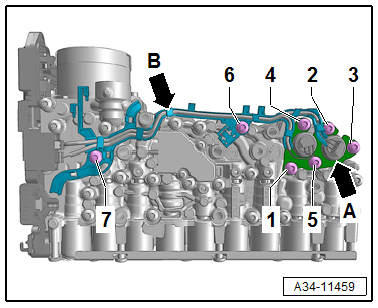

- Loosen the bolts in the sequence -7 to 1-.

- Remove the Hydraulic Pressure Sensor 1 -G545--1- and Hydraulic Pressure Sensor 2 -G546- with the retaining plate -arrow A- and wiring guide -arrow B-.

Installing

Note

Note

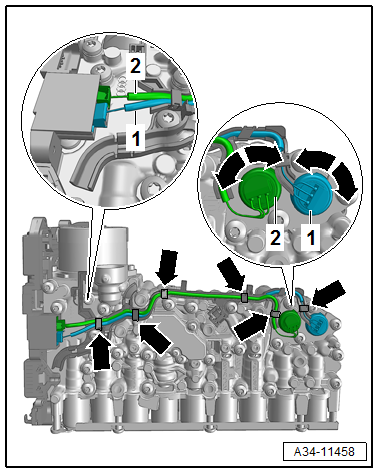

Replace the wiring guide -2-.

- Coat the new seal -1- with ATF and install in the valve body as shown.

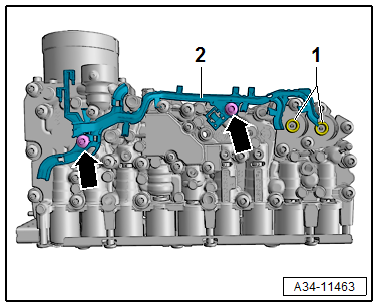

- Install the wiring guide -2- with both bolts -arrows- hand-tight.

- Install the Hydraulic Pressure Sensor 1 -G545--1- and Hydraulic Pressure Sensor 2 -G546- with the retaining plate -arrow A- and bolts -1 to 5- hand-tight.

- Clip in the Hydraulic Pressure Sensor 1 -G545--1- and Hydraulic Pressure Sensor 2 -G546- in the wiring guide and engage on the Transmission Control Module -J217-.

Note

Note

- Pay attention that the cable routing is even.

- The cables must not stick out or be kinked.

- Adapt the cable routing by turning the pressure sensors -arrows- as shown.

- Tightening specification and sequence. Refer to → Chapter "Overview - Mechatronic".

- Install the transmission fluid pan. Refer to → Chapter "Transmission Fluid Pan, Removing and Installing".

- After replacing the Hydraulic Pressure Sensor 1 -G545--1- and Hydraulic Pressure Sensor 2 - G546- the calibration of the clutch valve must be performed in the Transmission Control Module -J217-.

Procedure

- Connect the Vehicle Diagnostic Tester.

- Select Diagnostic mode and start the diagnostic.

- Select the Test plan tab.

- Select individual test button and select the following tree structure one after the other:

- Drivetrain

- 7-Speed Dual Clutch Transmission 0CK/0CL

- 01 - OBD-capable systems

- 02 - Transmission electronics 0CK

- 02 - Transmission electronics, functions

- 02 - Basic setting ⇒ clutch valve calibration

Transmission Fluid Auxiliary Hydraulic Pump -V552-, Removing and Installing

Special tools and workshop equipment required

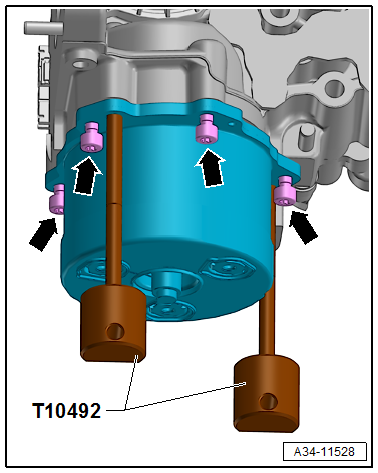

- Locking Pin -T10492-

- Electronic Torque Wrench 3-60Nm -VAS6583-

WARNING

WARNING

The system is under pressure.

- Deactivate the ATF pump and drain the hydraulic pressure reservoir before removing the transmission fluid pan!

- Refer to → Chapter "ATF Pump, Deactivating and Draining the Hydraulic Pump Reservoir".

Caution

Caution

Contamination damages the Mechatronic.

A clean work environment is required for working on the Mechatronic.

Removing

- Remove the Mechatronic. Refer to → Chapter "Mechatronic, Removing and Installing".

- Remove the Transmission Control Module -J217-. Refer to → Chapter "Transmission Control Module -J217-, Removing and Installing".

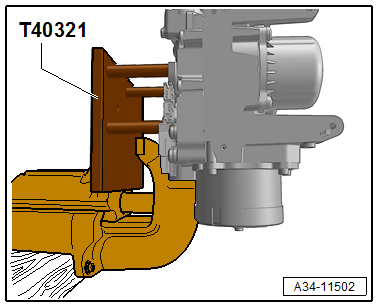

- Secure the Mechatronic on the vise with the Support -T40321- as shown.

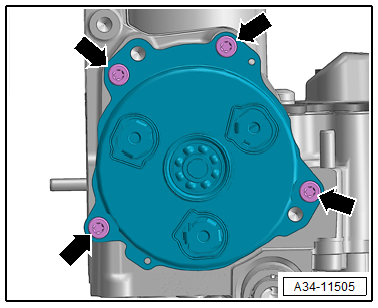

- Remove the bolts -arrows-.

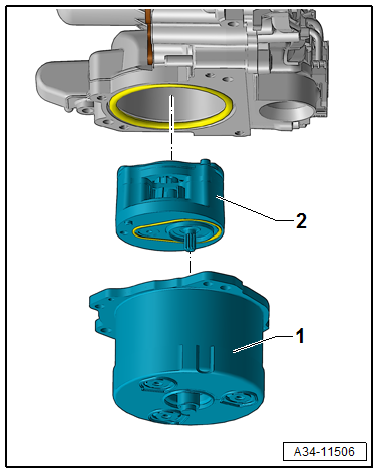

- Remove the ATF motor -1- with the ATF pump -2- downward at the same time pay attention that the ATF pump -2- does not fall down.

Installing

Caution

Caution

Contamination damages the Mechatronic.

A clean work environment is required for working on the Mechatronic.

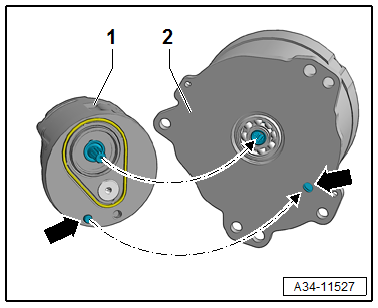

- Place the ATF pump on the ATF motor at the same time pay attention to the correct alignment of the anti-twist mechanism -arrows-.

- Drive the ATF motor and ATF pump using the Locking Pin - T10492- in the valve body.

- Install the bolts evenly all the way and tighten.

Tightening specification.

- Refer to → Chapter "Overview - Valve Body".

- Install the Transmission Control Module -J217-. Refer to → Chapter "Transmission Control Module -J217-, Removing and Installing".

- After replacing the Transmission Fluid Auxiliary Hydraulic Pump -V552- the function "calibrating the fluid auxiliary hydraulic pump" must be performed. Refer to Vehicle Diagnostic Tester.

Procedure

- Connect the Vehicle Diagnostic Tester.

- Select Diagnostic mode and start the diagnostic.

- Select the Test plan tab.

- Select individual test button and select the following tree structure one after the other:

- Drivetrain

- 7-Speed Dual Clutch Transmission 0CK/0CL

- 01 - OBD-capable systems

- 02 - Transmission electronics 0CK

- 02 - Transmission electronics, functions

- 02 - Basic setting ⇒ fluid auxiliary hydraulic pump calibration

- Checking the ATF level. Refer to → 7-Speed Dual Clutch Transmission 0CK; Rep. Gr.34; ATF; ATF Level, Checking.