Audi A4: Overview - Subframe

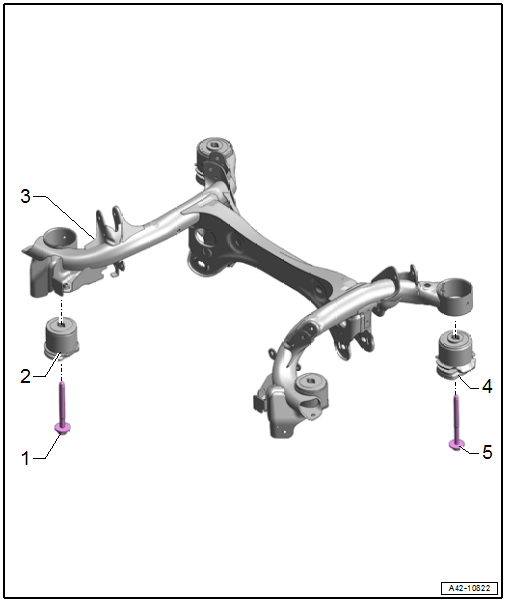

Overview - Subframe, FWD

Caution

Caution

There is a risk of damaging the threads on the subframe threaded connection to the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

1 - Bolt

- 130 Nm + 180º

- Replace after removing

2 - Front Bonded Rubber Bushing

- For the subframe

3 - Subframe

- Removing and installing. Refer to → Chapter "Subframe, Removing and Installing".

4 - Rear Bonded Rubber Bushing

- For the subframe

5 - Bolt

- 90 Nm + 180º

- Replace after removing

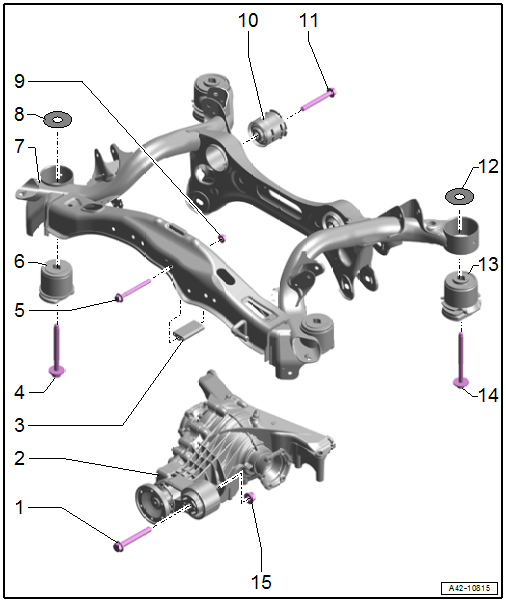

Overview - Subframe, AWD

Caution

Caution

There is a risk of damaging the threads on the subframe threaded connection to the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

1 - Bolt

- Replace after removing

2 - Rear Final Drive

3 - Stop Buffer

4 - Bolt

- 130 Nm + 180º

- Replace after removing

5 - Bolt

6 - Front Bonded Rubber Bushing

- For the subframe

7 - Subframe

- Securing. Refer to → Chapter "Subframe, Securing".

- Removing and installing. Refer to → Chapter "Subframe, Removing and Installing".

8 - Spacer

- Installed depending on the model

9 - Nut

- 20 Nm

10 - Rear Bonded Rubber Bushing

- For the rear final drive

- Removing and installing. Refer to → Chapter "Rear Bonded Rubber Bushing for Rear Final Drive, Removing and Installing".

- Installation position. Refer to → Fig. "Rear Bonded Rubber Bushings Installation Position for the Rear Final Drive".

11 - Bolt

- Tightening specification. Refer to → Rear Final Drive; Rep. Gr.39; Subframe Mount; Overview - Subframe Mount.

12 - Spacer

- Installed depending on the model

13 - Rear Bonded Rubber Bushing

- For the subframe

14 - Bolt

- 90 Nm + 180º

- Replace after removing

15 - Nut

- Tightening specification. Refer to → Rear Final Drive; Rep. Gr.39; Subframe Mount; Overview - Subframe Mount.

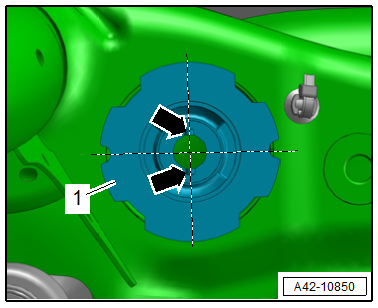

Rear Bonded Rubber Bushings Installation Position for the Rear Final Drive

- The grooves -arrows- on the bonded rubber bushings -1- are at a right angle.

READ NEXT:

Subframe, Securing

Subframe, Securing

Special tools and workshop equipment required

Torque Wrench 1331 5-50Nm -VAG1331-

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Gearbox Support -T40173-

Locating Pins -

Subframe, Removing and Installing

Subframe, Removing and Installing

Caution

This procedure contains mandatory replaceable parts.

Refer to component overview and parts catalog prior to

starting procedure.

Mandatory Replacement Parts

Bolt - Bonded Rubber Bu

Stabilizer Bar

Stabilizer Bar

Overview - Stabilizer Bar

1 - Bolt

25 Nm + 90º

Replace after removing

Tighten in the curb weight position. Refer to

→ Chapter "Wheel Bearing in Curb Weight Position, Lifting Ve

SEE MORE:

Additional Safety Precautions for Airbag Control Module

Additional Safety Precautions for Airbag Control Module

WARNING

After every removal and installation of the Airbag

Control Module -J234-, the "inertial sensor basic

setting" must be performed.

If the Airbag Control Module -J234- is replaced with a

new part, the basic setting is performed when

implementing the "15 - Replace airbag control

Fuses

Fuses

Replacing fuses

Fig. 181 Driver's side footwell (left-hand drive vehicles):

footrest 1, front passenger's side footwell (right-hand

drive vehicles): cover 2

Fig. 182 Driver's side cockpit (left-hand drive/right-hand

drive vehicles): cover (C), left side of luggage compartment:

cover (D)

Fuses are

© 2019-2026 Copyright www.audia4b9.com