Audi A4: Stabilizer Bar

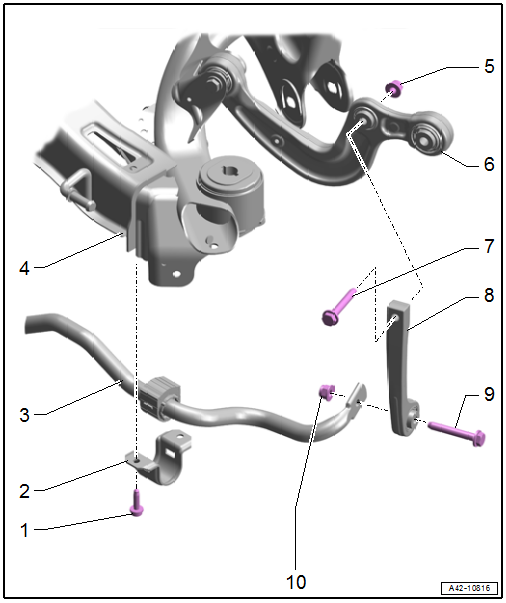

Overview - Stabilizer Bar

1 - Bolt

- 25 Nm + 90Âş

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Tighten alternating in stages

2 - Clamp

3 - Stabilizer Bar

- Removing and installing. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

- Do not separate the bonded rubber bushing from the stabilizer bar

4 - Subframe

5 - Nut

- Replace after removing

6 - Front Upper Transverse Link

7 - Bolt

- 40 Nm + 180Âş

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

8 - Coupling Rod

- Removing and installing. Refer to → Chapter "Coupling Rod, Removing and Installing".

9 - Bolt

- 40 Nm + 180Âş

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

10 - Nut

- Replace after removing

Stabilizer Bar, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Mandatory Replacement Parts

- Bolt/Nut - Coupling Rod to Stabilizer Bar

- Bolt - Stabilizer Bar Clamp to Subframe

Removing

- Before starting the procedure, determine the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Equipped on some models: Remove the right diagonal brace. Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Diagonal Braces, Removing and Installing.

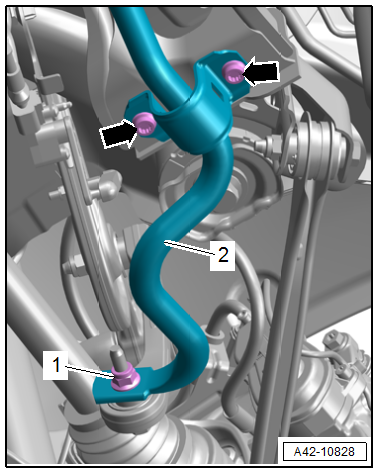

- Remove the left and right bolts -arrows-.

- Disconnect the left and right threaded connection -1- and remove the stabilizer bar -2-.

Note

Note

The installation position is shown for the AWD equipment version.

Installing

Install in reverse order of removal.

Tightening Specifications

- Refer to → Chapter "Overview - Stabilizer Bar"

- Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Overview - Underbody Trim Panels.

Coupling Rod, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Mandatory Replacement Parts

- Bolt/Nut - Coupling Rod to Front Upper Transverse Link

- Bolt/Nut - Coupling Rod to Stabilizer Bar

Removing

- Before starting the procedure, determine the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

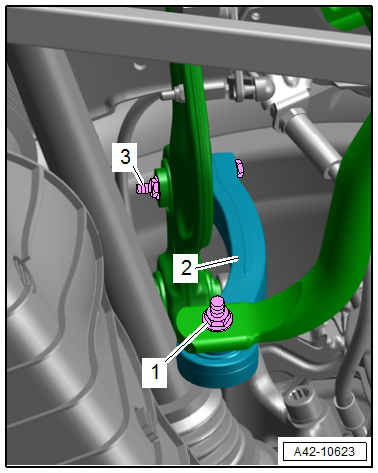

- Disconnect the connectors -1 and 3- and remove the coupling rod -2-.

Note

Note

The installation position is shown for the AWD equipment version.

Installing

Install in reverse order of removal.

Tightening Specifications

- Refer to → Chapter "Overview - Stabilizer Bar"