Audi A4: Overview - Transverse Link

Audi A4 (B9) 2016-2026 Service Manual / Chassis / Rear Suspension / Control Arm, Tie Rod / Overview - Transverse Link

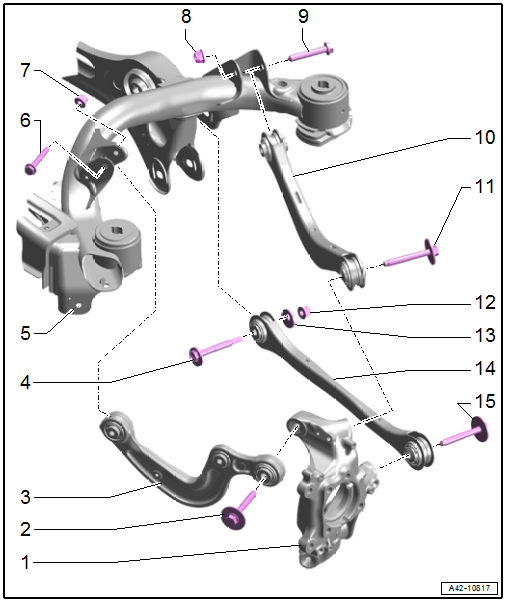

Upper Transverse Link

1 - Wheel Bearing Housing

2 - Bolt

- 70 Nm + 180º

- Replace after removing

3 - Front Upper Transverse Link

- Removing and installing. Refer to → Chapter "Front Upper Transverse Link, Removing and Installing".

- Installation position. Refer to → Fig. "Transverse Link and Tie Rod Installation Position".

4 - Eccentric Bolt

5 - Subframe

6 - Bolt

- 40 Nm + 180º

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

7 - Nut

- Replace after removing

8 - Nut

- Replace after removing

9 - Bolt

- 70 Nm + 180º

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

10 - Rear Upper Transverse Link

- Removing and installing. Refer to → Chapter "Rear Upper Transverse Link, Removing and Installing".

- Installation position. Refer to → Fig. "Transverse Link and Tie Rod Installation Position".

11 - Bolt

- 70 Nm + 180º

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

12 - Nut

- 110 Nm

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

13 - Eccentric Washer

14 - Tie Rod

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing".

- Installation position. Refer to → Fig. "Transverse Link and Tie Rod Installation Position".

15 - Bolt

- 70 Nm + 180º

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

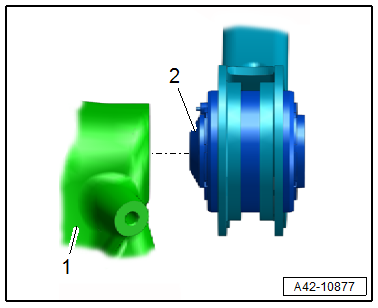

Transverse Link and Tie Rod Installation Position

- The ball side -2- on the transverse link or tie rod must engage in the wheel bearing housing -1-.

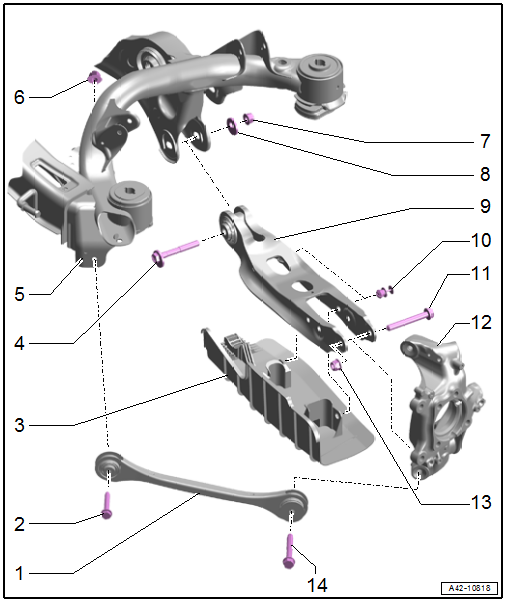

Lower Transverse Link

1 - Front Lower Transverse Link

- Removing and installing. Refer to → Chapter "Front Lower Transverse Link, Removing and Installing".

- Installation position. Refer to → Fig. "Transverse Link and Tie Rod Installation Position".

2 - Bolt

- Replace after removing

3 - Wind Deflector

4 - Eccentric Bolt

5 - Subframe

6 - Nut

- 40 Nm + 180º

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

7 - Nut

- 160 Nm

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Loosen and tighten using the 21 mm 6-edge socket wrench

8 - Eccentric Washer

9 - Rear Lower Transverse Link

- Removing and installing. Refer to → Chapter "Rear Lower Transverse Link, Removing and Installing".

10 - Expanding Rivet

11 - Bolt

- Replace after removing

12 - Wheel Bearing Housing

13 - Nut

- 70 Nm + 180º

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

14 - Bolt

- 70 Nm + 180º

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

READ NEXT:

Upper Transverse Link, Removing and Installing

Upper Transverse Link, Removing and Installing

Front Upper Transverse Link, Removing and Installing

Special tools and workshop equipment required

Torque Wrench 1332 40-200Nm -VAG1332-

Caution

This procedure contains mandatory replaceab

Lower Transverse Link, Removing and Installing

Lower Transverse Link, Removing and Installing

Rear Lower Transverse Link, Removing and Installing

Special tools and workshop equipment required

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Engine/Gearbox Jack Adapte

Tie Rod, Removing and Installing

Tie Rod, Removing and Installing

Special tools and workshop equipment required

Torque Wrench 1332 40-200Nm -VAG1332-

Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

Engine and Gearbox Jack -VAS6931-

Caution

Thi

SEE MORE:

Front Axle Camber, Centering

Front Axle Camber, Centering

Note

Camber cannot be adjusted.

Camber can be centered evenly within specified tolerance

range by shifting subframe.

Procedure

- Remove the noise insulation. Refer to

→ Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation,

Removing and Installing.

-

Bulkhead

Bulkhead

Overview - Bulkhead

1 -

Lock Washer

2 -

Heat Shield

Overview. Refer to

→ Chapter "Overview - Heat Shield".

3 -

Pass-Through

For coolant lines

Can be replaced only with the heat shield

Equipped on some models

4 -

Seal

For the plenum chamber bu

© 2019-2026 Copyright www.audia4b9.com