Audi A4: Control Arm, Removing and Installing

Special tools and workshop equipment required

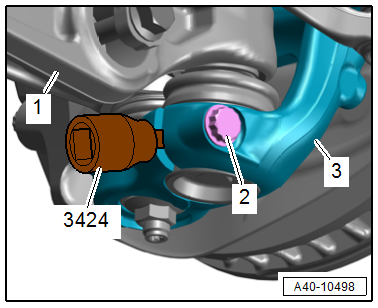

- Spreader Tool -3424-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

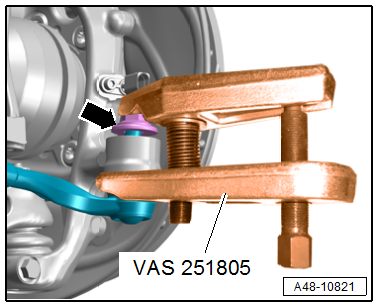

- Ball Joint Splitter -VAS251805-

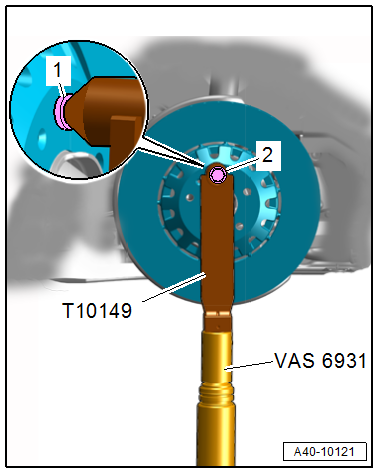

- Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Mandatory Replacement Parts

- Bolt/Nut - Control Arm to Subframe

- Bolt - Control Arm to Shock Absorber Fork

- Nut - Ball Joint to Control Arm

Removing

- Before starting the procedure, determine the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Remove the front wheel. Refer to → Chapter "Wheels and Tires".

- Remove the noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

- To protect the threads, remove the nut -arrow- from the tie rod end joint pin until it is flush with the joint pin threads.

WARNING

WARNING

There is a risk of injury from falling components.

When pressing off, the tie rod end loosens abruptly from the wheel bearing housing. Use, for example, the -VAS6931- to secure.

Caution

Caution

There is a risk of damaging the ball joint puller.

Make sure that both puller lever arms are parallel to each other when using maximum force.

- Remove the tie rod end with the -VAS251805- from the wheel bearing housing.

- Then remove the nut. Use a 6 mm inner hex socket to counterhold at the joint pin if necessary.

- Tie up the tie rod.

Note

Note

To prevent the joints on the upper control arm from being damaged, support the wheel bearing housing against too strong rebound.

- Turn the wheel hub, until a wheel bolt hole is at the top.

- Install the -T10149- with a wheel bolt -2- on the wheel hub.

Note

Note

Ignore item -1-.

- Support the wheel bearing housing over the -T10149- using the -VAS6931-.

WARNING

WARNING

Risk of accident!

- Do not lift or lower the vehicle when the -VAS6931- is under the vehicle.

- Do not leave the -VAS6931- under the vehicle any longer than necessary.

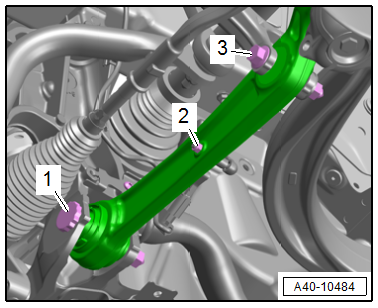

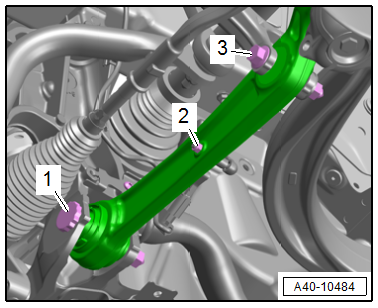

- Equipped on some models: remove the nut -2- and free up the coupling rod for the level control system sensor.

- Disconnect the threaded connections -1 and 3- for the control arm.

- Pivot the control arm toward the front.

Note

Note

To remove the bolt -1-, push the steering all the way to the left or right.

- Remove the bolt -2-.

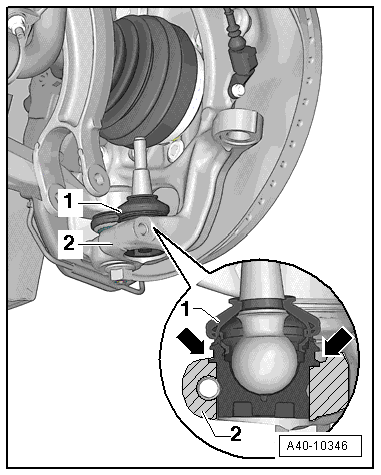

- Insert the -3424- into the slit on the wheel bearing housing -3- and turn 90º.

- Remove the control arm -1- with the ball joint.

Installing

Install in reverse order of removal and note the following:

- When reusing the ball joint, clean any remaining locking compound residue off the pin threads.

- Bring the control arm with the ball joint into the installation position.

Caution

Caution

There is a risk of damage occurring in the threaded connection area on the wheel bearing housing if the installation position is incorrect.

Insert the ball joint -1- into the wheel bearing housing -2- up to the contact surface -arrows-.

- Install the threaded connections for the components with bonded rubber bushings only until the stop, but do not tighten yet.

Note

Note

Bonded rubber bushings have a limited range of rotation. Only tighten the threaded connections for the suspension when the vehicle is in curb weight position.

- Lift the wheel bearing in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- When tightening the threaded connection -1-, the control arm must be pressed toward the inside of the vehicle.

- Overview table for when an axle alignment is needed. Refer to → Chapter "Need for Axle Alignment, Evaluating".

- Adjust the headlamps. Refer to → Electrical Equipment; Rep. Gr.94; Headlamps; Headlamps, Adjusting.

- Driver assistance systems front camera, calibrating. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

Tightening Specifications

- Refer to → Chapter "Overview - Lower Control Arm and Ball Joint"

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

- Refer to → Chapter "Wheels and Tires"