Audi A4: Lower Transverse Link, Removing and Installing

Rear Lower Transverse Link, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

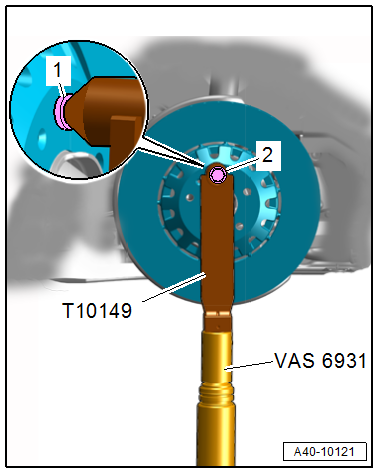

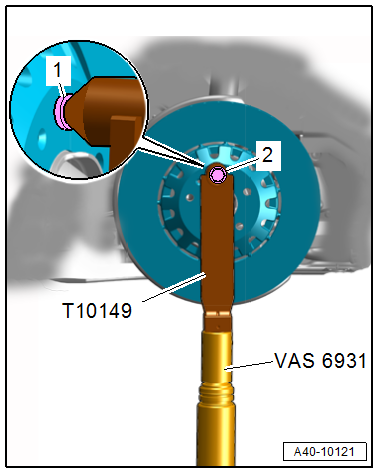

- Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Mandatory Replacement Parts

- Bolt - Rear Lower Transverse Link to Subframe

- Bolt/Nut - Rear Lower Transverse Link to Wheel Bearing Housing

Removing

- Before starting the procedure, determine the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Remove the spring. Refer to → Chapter "Spring, Removing and Installing".

- Turn the wheel hub, until a wheel bolt hole is at the top.

- Install the -T10149- with a wheel bolt -2- on the wheel hub.

Note

Note

Ignore item -1-.

- Slightly lift the wheel bearing housing using the -T10149- with the -VAS6931- this allows the threaded connections to easily separate.

WARNING

WARNING

Risk of accident!

- Do not lift or lower the vehicle when the -VAS6931- is under the vehicle.

- Do not leave the -VAS6931- under the vehicle any longer than necessary.

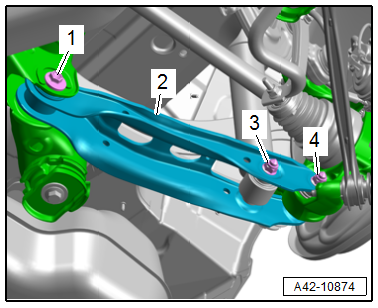

- FWD equipment version: Disconnect the threaded connection -3-.

- Disconnect the threaded connections -1 and 4- and remove the lower transverse link -2-.

Installing

Install in reverse order of removal and note the following:

- Install the threaded connections up to the stop but do not tighten yet.

Note

Note

Bonded rubber bushings have a limited range of rotation. Only tighten the threaded connections for the suspension when the vehicle is in curb weight position.

- Lift the wheel bearing in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Overview table for when an axle alignment is needed. Refer to → Chapter "Need for Axle Alignment, Evaluating".

Tightening Specifications

- Refer to → Chapter "Overview - Transverse Link"

Front Lower Transverse Link, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

- Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Mandatory Replacement Parts

- Bolt - Front Lower Transverse Link to Subframe

- Bolt - Front Lower Transverse Link to Wheel Bearing Housing

Removing

- Before starting the procedure, determine the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Remove the rear wheel. Refer to → Chapter "Wheels and Tires".

- Loosen the rear underbody trim panel in the rear area and push slightly downward. Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Underbody Trim Panels, Removing and Installing.

- Turn the wheel hub, until a wheel bolt hole is at the top.

- Install the -T10149- with a wheel bolt -2- on the wheel hub.

Note

Note

Ignore item -1-.

- Slightly lift the wheel bearing housing using the -T10149- with the -VAS6931- this allows the threaded connections to easily separate.

WARNING

WARNING

Risk of accident!

- Do not lift or lower the vehicle when the -VAS6931- is under the vehicle.

- Do not leave the -VAS6931- under the vehicle any longer than necessary.

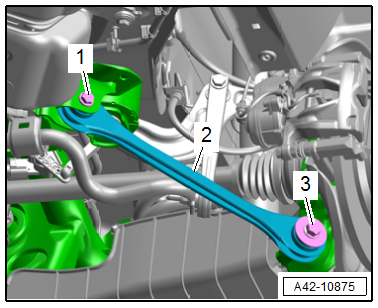

- Disconnect the threaded connection -1- on the left side of the vehicle.

- Disconnect the threaded connection -1- on the right side of the vehicle, attach the subframe and lower. Refer to → Chapter "Subframe, Securing".

- Remove the bolt -3- and remove the lower transverse link -2-.

Installing

Install in reverse order of removal and note the following:

- Installation position. Refer to → Fig. "Transverse Link and Tie Rod Installation Position".

- Attach the subframe to the right side of the vehicle using Locating Pins -T40327-. Refer to → Chapter "Subframe, Securing".

- Install the threaded connections up to the stop but do not tighten yet.

Note

Note

Bonded rubber bushings have a limited range of rotation. Only tighten the threaded connections for the suspension when the vehicle is in curb weight position.

- Lift the wheel bearing in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Overview table for when an axle alignment is needed. Refer to → Chapter "Need for Axle Alignment, Evaluating".

Tightening Specifications

- Refer to → Chapter "Overview - Transverse Link"

- Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Overview - Underbody Trim Panels.

- Refer to → Chapter "Wheels and Tires".