Audi A4: Subframe, Securing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

- Gearbox Support -T40173-

- Locating Pins -T40327-, not illustrated

- Engine Support Bridge -10-222A-

Procedure

WARNING

WARNING

There is a risk of an accident due to an unsecured engine/transmission subassembly!

The engine must be supported in the installation position for the following steps.

- Support the engine in the installation position. Refer to → Rep. Gr.10; Subframe Mount; Engine, Supporting in Installation Position.

- Remove the front wheels. Refer to → Chapter "Wheels and Tires".

- Remove the noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

- Remove the left and right wheel spoilers. Refer to → Body Exterior; Rep. Gr.66; Wheel Housing Liner; Front Wheel Housing Liner, Removing and Installing.

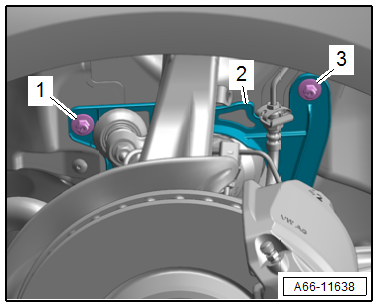

- Remove the nuts -1 and 3- and remove the drive axle cover -2-.

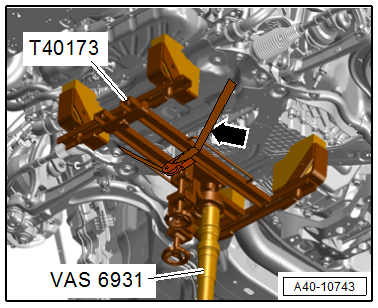

- Support the subframe with the -VAS6931- and the -T40173- as shown.

- Secure the subframe with the tensioning strap -arrow-.

Caution

Caution

There is a risk of damaging the threads on the subframe threaded connection to the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

Note

Note

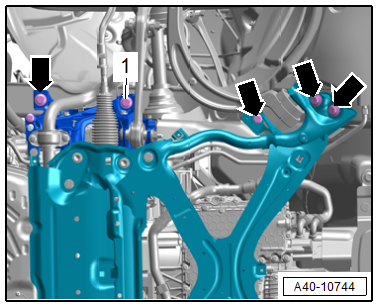

- To secure the subframe, a -T40327- must be installed at position -1- on the left and right side.

- The locating pins must only be tightened to a maximum of 20 Nm or else the locating pin bolts will be damaged.

- Due to the ribbed washers for the bolts, the holes for the subframe are slightly peened. They must be deburred if necessary.

- Replace the bolts -1- on both sides of the vehicle with the -T40327- and tighten to 20 Nm.

- The suspension is now secured.

- Remove the bolts on the left and right side -arrows-.

Remove the -T40327-

Removal is performed in the reverse order. Note the following:

- Remove the locating pins and tighten a new bolt at this position.

Caution

Caution

There is a risk of damaging the threads on the subframe threaded connection to the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

WARNING

WARNING

Risk of accident!

If the vehicle will be driving on the streets, all bolts and nuts must be tightened properly according to the guidelines.

- Remove the -10-222A-. Refer to → Rep. Gr.10; Subframe Mount; Engine, Supporting in Installation Position.

- A road test must be performed after completing repairs. If the steering wheel is crooked, the wheels must be aligned. Refer to → Chapter "Axle Alignment".

Tightening Specifications

- Refer to → Chapter "Overview - Subframe"

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

- Refer to → Body Exterior; Rep. Gr.66; Wheel Housing Liner; Overview - Front Wheel Housing Liner.

- Refer to → Chapter "Wheels and Tires"