Audi A4: Transmission, Disassembling and Assembling

WARNING

WARNING

The system is under pressure.

- The electronic ATF pump must be deactivated every time before opening the transmission, and the hydraulic pressure reservoir is drained.

- Refer to → Chapter "ATF Pump, Deactivating and Draining the Hydraulic Pump Reservoir".

FWD Vehicles

Special tools and workshop equipment required

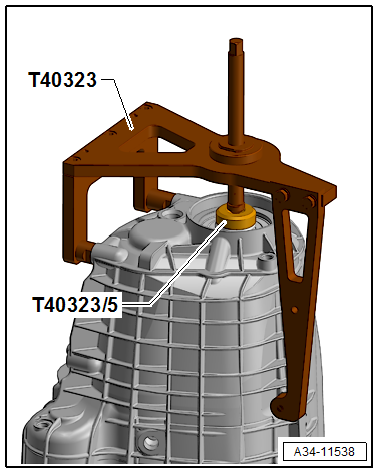

- Press Tool -T40323-

- Assembly Tool -T40305-

- Slide Hammer Set -VW771-

- Gearbox Assembly Tool -T40213 /1/2/3-

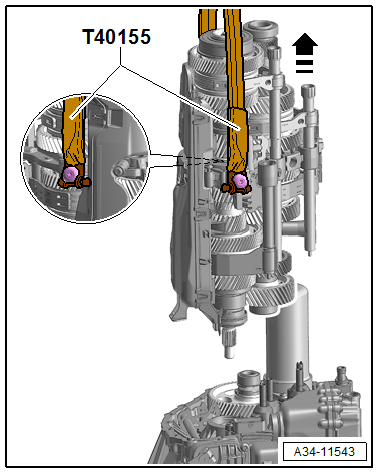

- Retaining Strap -T40155-

- Shop Crane -VAS6100-

- Puller - Grease Cap -VW637/2-

- Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A-

Caution

Caution

Risk of damaging the transmission by mixing ATF and transmission fluid (MTF) through the same bleeder.

The ATF and transmission fluid must be drained.

Removing

- Draining the ATF. Refer to → Rep. Gr.34; ATF, Draining and Filling.

- Draining the transmission fluid. Refer to → Rep. Gr.34; Transmission Fluid, Draining and Filling.

- Remove the clutch. Refer to → Chapter "Dual Clutch, Removing and Installing".

- Remove the transmission fluid pan. Refer to → Chapter "Transmission Fluid Pan, Removing and Installing".

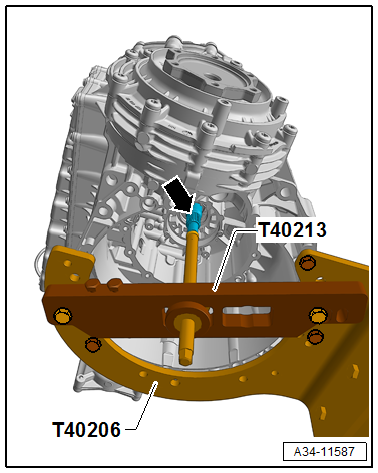

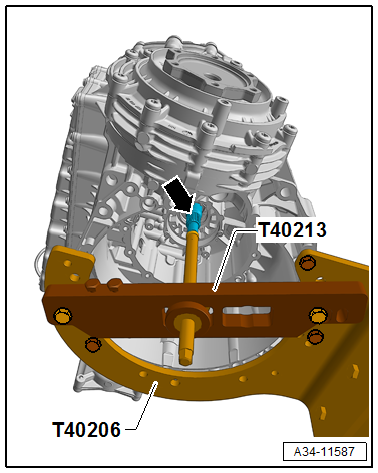

- Turn the transmission on the Gearbox Support -T40206- 180º.

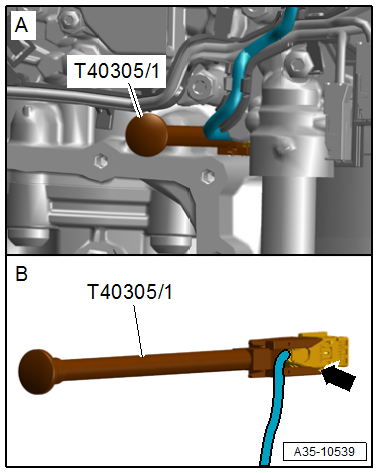

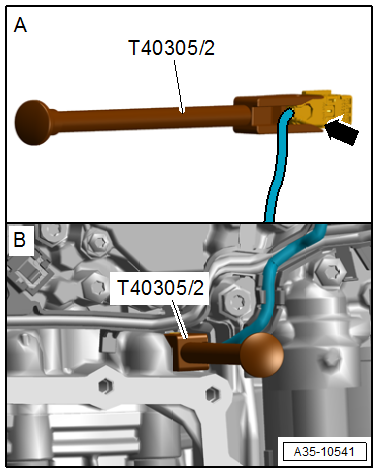

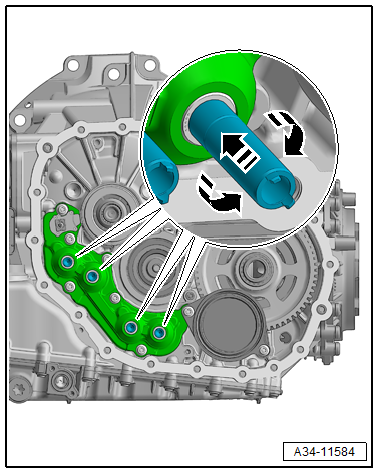

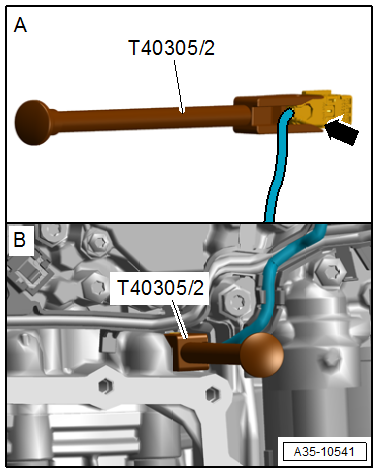

- Disconnect the connector -arrow- using the Assembly Tool -T40305-.

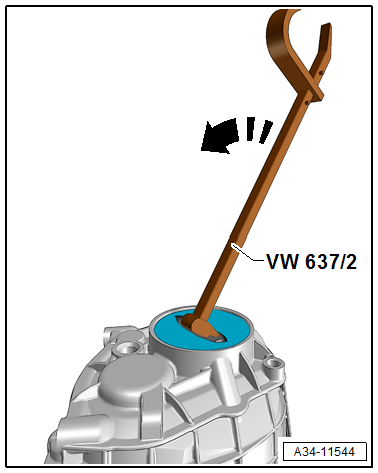

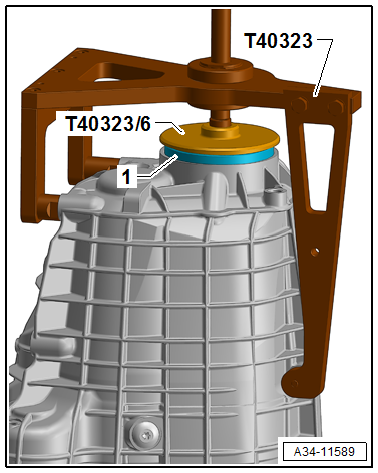

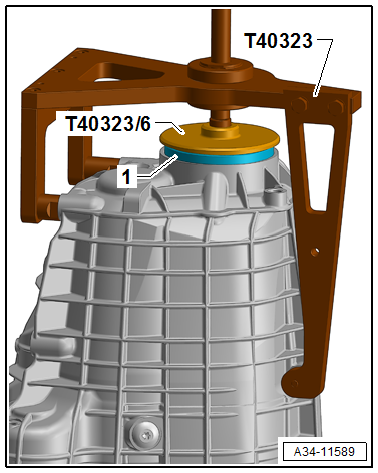

- Remove the end cover to do so chisel the center of the cover and remove using the Puller - Grease Cap -VW637/2- as shown.

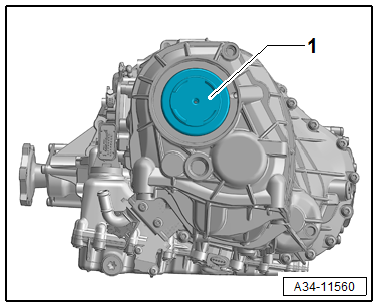

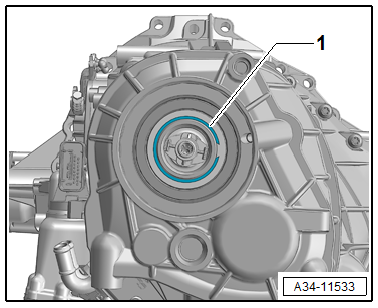

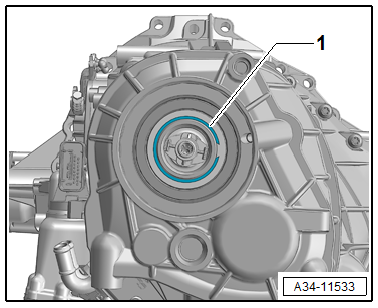

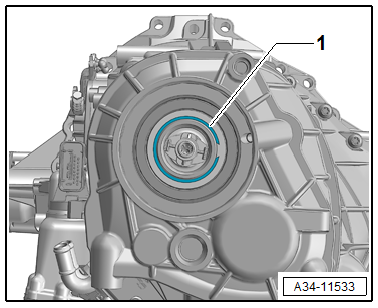

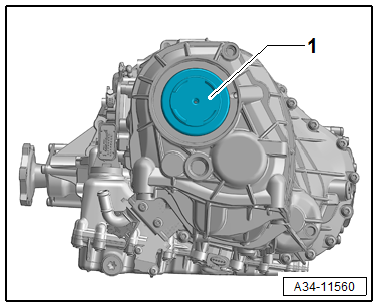

- Remove the oil catch tray -1-.

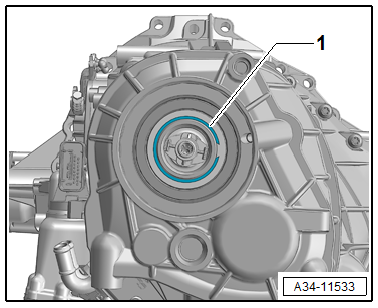

- Remove the circlip -1-.

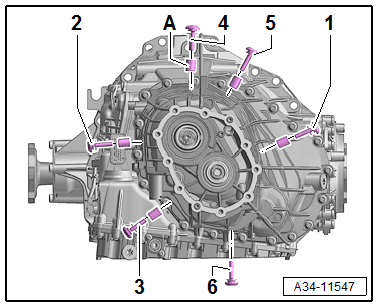

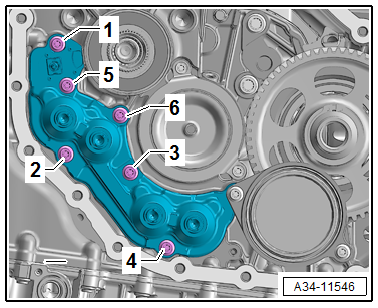

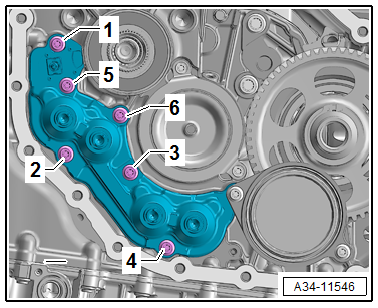

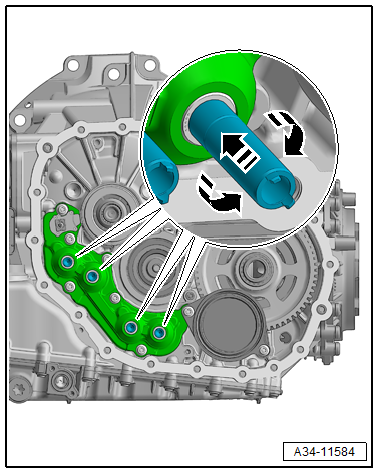

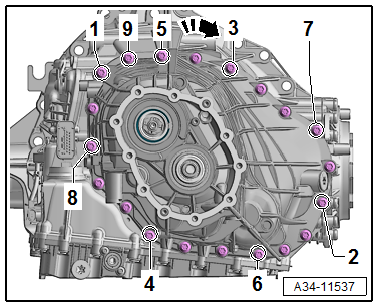

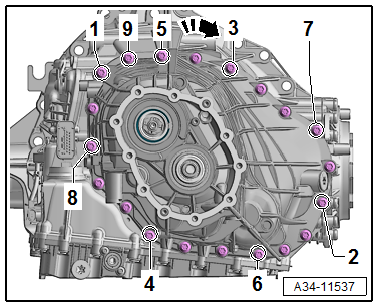

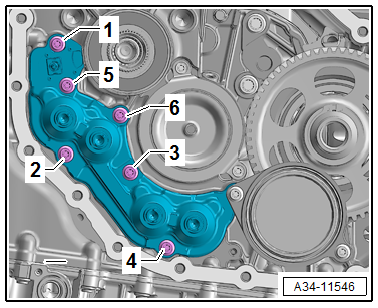

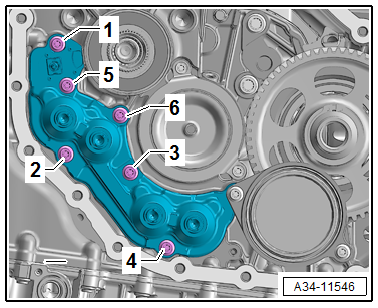

- Remove the bolts -1 to 6-.

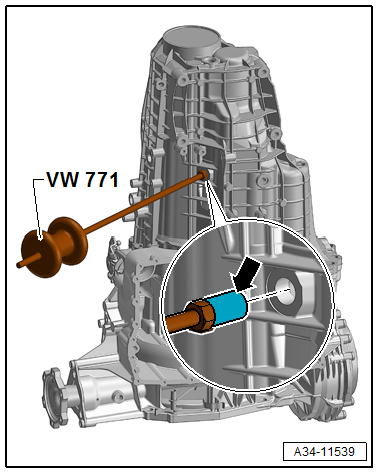

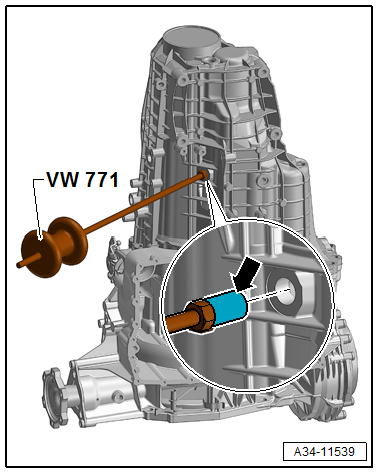

- Remove the centering bushing -arrows- with the Slide Hammer Set -VW771-.

Note

Note

Bolt -6- without centering bushing.

- Remove the bolts for the transmission housing.

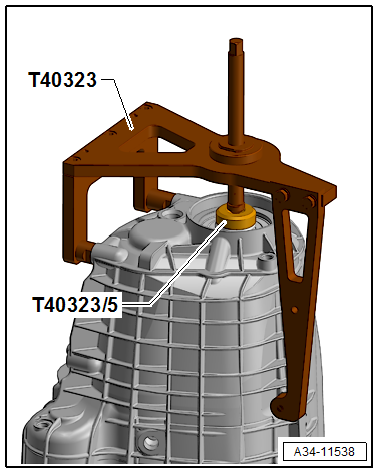

- Remove the transmission housing with the Press Tool -T40323-.

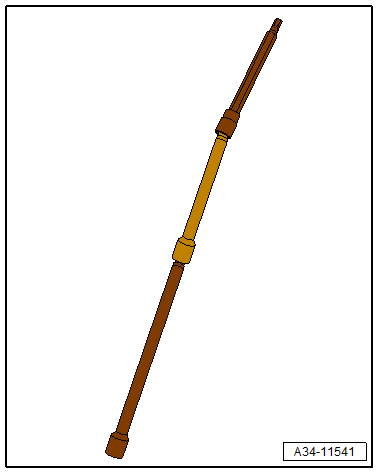

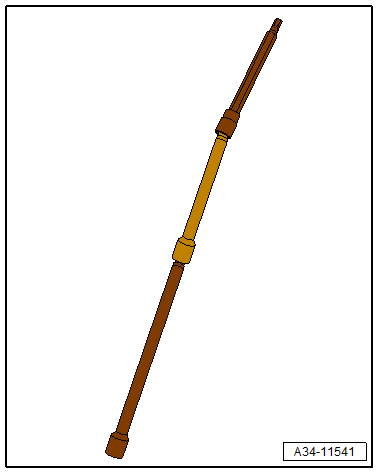

- Prepare the 1/4 inch tool with Torx T30 and flexible extension as shown.

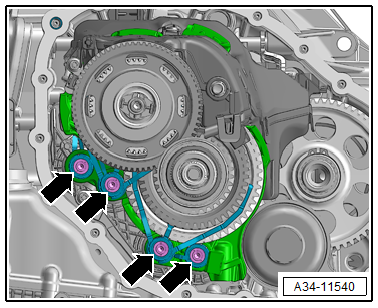

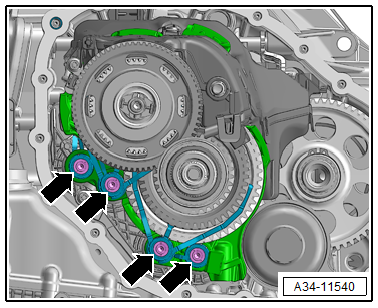

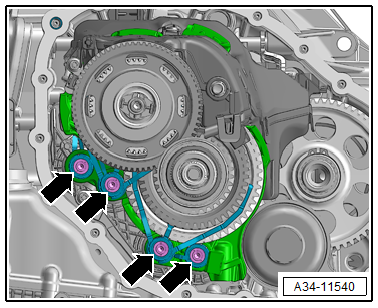

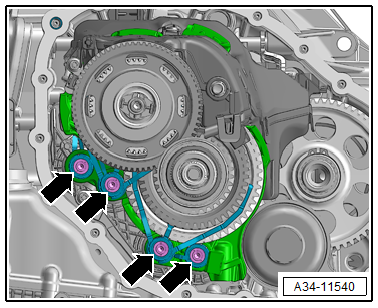

- Remove the bolts for the gear positioner -arrows-.

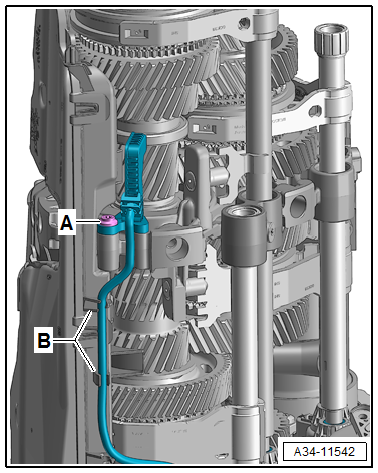

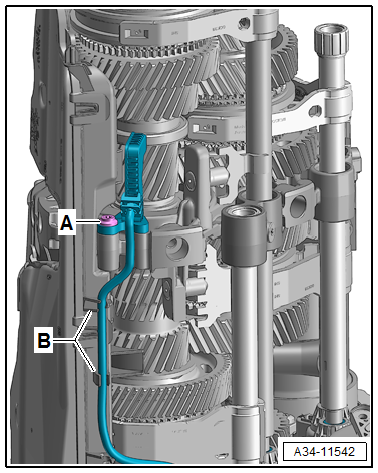

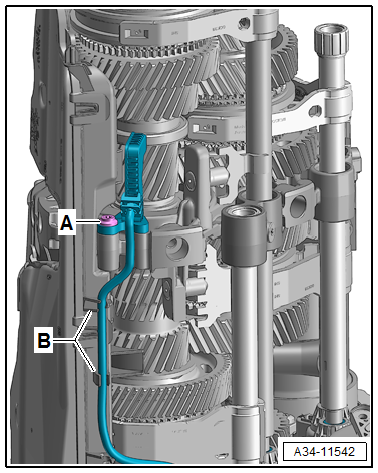

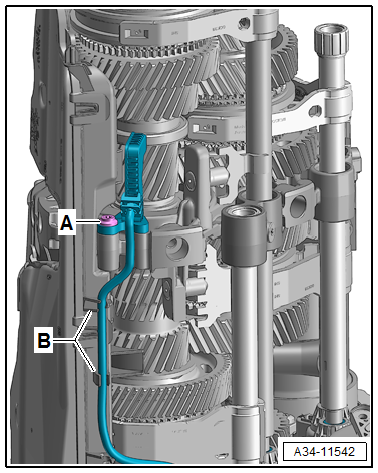

- Remove the bolt for the Transmission Input Speed Sensor 1 -G632--arrow A- and remove the line from the oil pan -arrow B-.

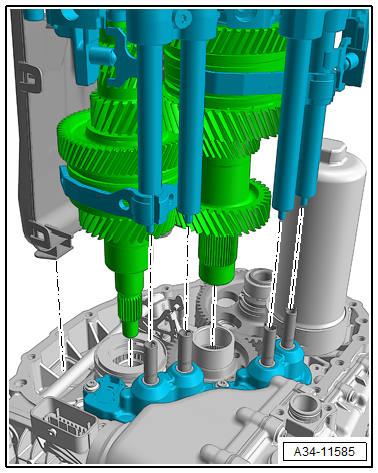

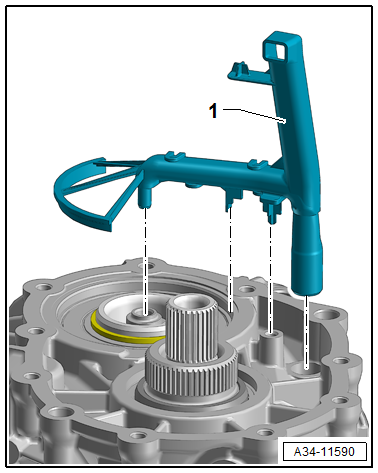

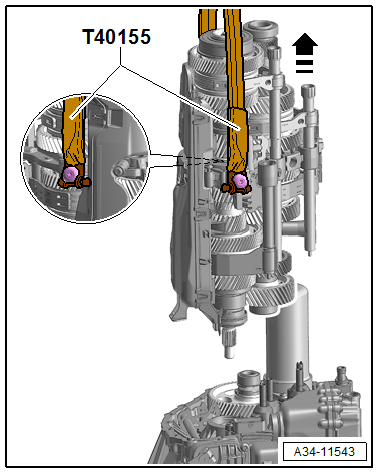

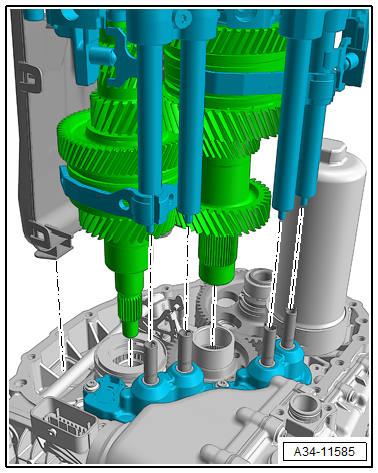

- Secure the Retaining Strap -T40155- on the gear set as shown and slowly and carefully remove with the Shop Crane -VAS6100- from the transmission housing.

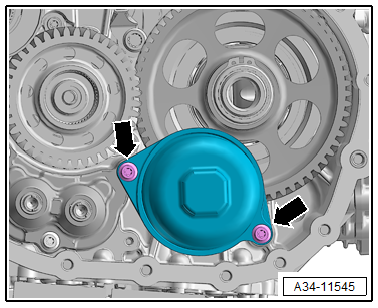

- Loosen the bolts -arrow- for the hydraulic pressure reservoir but do not remove.

Note

Note

- If the hydraulic pressure reservoir lifts when loosening the bolts the ATF system is still under pressure.

- In this case the bolts from the Mechatronic must be minimally loosened to reduce the pressure in the ATF system via the sealing surfaces.

- Refer to → Chapter "ATF Pump, Deactivating and Draining the Hydraulic Pump Reservoir".

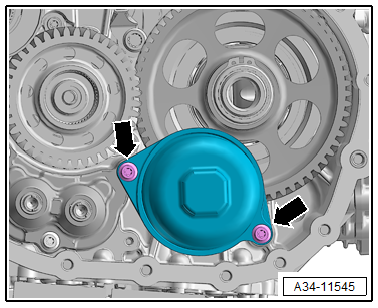

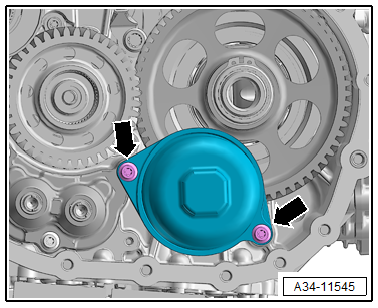

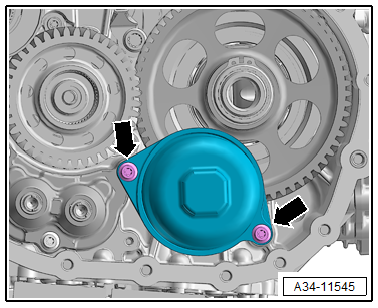

- Remove the bolts -arrows- and the hydraulic pressure reservoir.

- Remove the bolts -1 through 6- and remove the gear positioner module.

Installing

- Insert the gear positioner module and tighten the bolts in the sequence -1 to 6- hand-tight.

- Install the hydraulic pressure reservoir with new seals and tighten the bolts -arrow- hand-tight evenly.

- Tighten the gear positioner and pressure reservoir to the tightening specification. Refer to → Fig. "Gear Positioner and Pressure Reservoir Tightening Sequence".

- Bring the gear positioner into the basic setting.

- Push the gear positioner by hand and turn at the same time it until it engages and determine the current backlash.

- Carefully remove the gear set.

- Guide together the bearing area and gear positioner -arrows- evenly.

- Install the gear positioner -arrows- hand-tight.

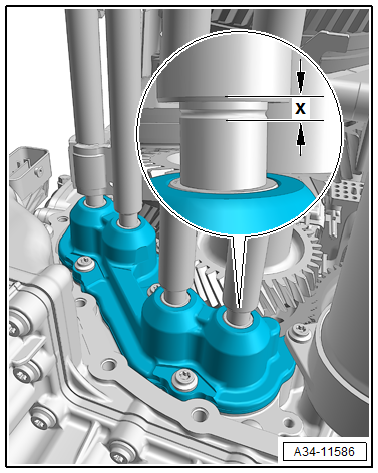

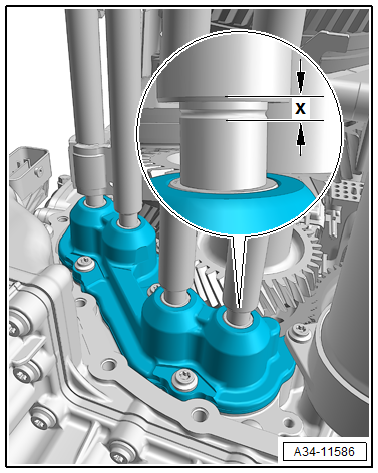

- When the gear positioner is installed correctly the dimension -X- is approximately 2 mm.

- Tighten the bolts for the gear positioner to the tightening specification. Refer to → Chapter "Overview - Gear Set, FWD Vehicles".

- Tighten the bolt -A- for the Transmission Input Speed Sensor 1 -G632- and install the line in the oil pan.

- Install the Gearbox Assembly Tool -T40213A- on the transmission.

Note

Note

This step is necessity to that the bearing "E" in the transmission housing can be mounted correctly on the shaft.

- Install the spindle from the Gearbox Assembly Tool -T40213A- by hand until the input shaft has raised approximately 2 to 3 mm and there is a small resistance when turning.

- Position the new seal and check if both centering pins are installed.

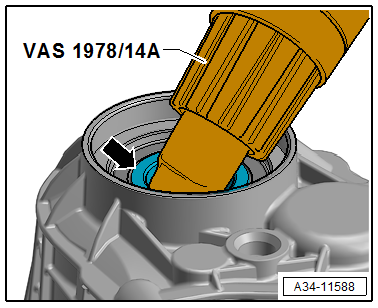

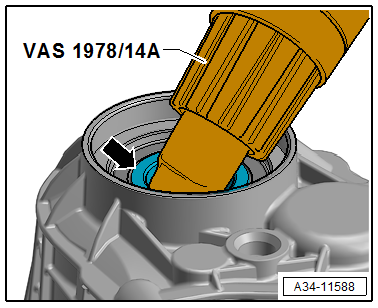

- Warm the inner race of the bearing "E"-arrow- with the Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A- to a maximum of 100 ºC (212 ºF).

Caution

Caution

Risk of damaging the bearing seal.

Only warm up the inner bearing race.

- Guide together the transmission housing and the transmission.

- Install the new circlip -1- for the bearing "E".

Note

Note

- The circlip had different installed dimensions.

- If the bearing "E" is not replaced, a circlip with the same dimension as the old circlip must be installed.

- For a new bearing "E" the largest possible circlip to be installed must be used.

- Remove the Gearbox Assembly Tool -T40213A- from the transmission.

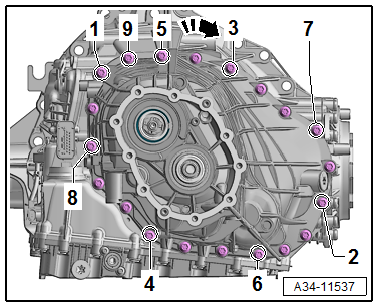

- Tighten the transmission housing with new bolts. Tightening sequence and tightening specification. Refer to → Chapter "Overview - Transmission, FWD Vehicles".

- Tighten the bolts for the transmission housing to the tightening sequence. Refer to → Fig. "Transmission Housing Tightening Specification and Sequence.".

- Push in the centering bracket -A- for the gear set all the way.

Note

Note

Bolt -6- without centering bracket.

- Tighten the new bolts for the gear set -1 to 6- with the tightening sequence. Refer to → Fig. "Wheel Set Tightening Specification and Sequence.".

- Install the oil catch tray -1-.

- Press in the new end cover with the Press Tool -T40323-.

Caution

Caution

Oil loss due to improper assembly.

- The end cover is installed "dry" in the cleaned housing, never use locking agent.

- Let the end cover be tensioned 10 minutes with the Press Tool -T40323-.

- Install the connector with the Assembly Tool -T40305-.

- Install the clutch. Refer to → Chapter "Dual Clutch, Removing and Installing".

- Install the transmission fluid pan. Refer to → Chapter "Transmission Fluid Pan, Removing and Installing".

- Fill the ATF. Refer to → Rep. Gr.34; ATF; ATF, Draining and Filling.

- Fill the transmission fluid. Refer to → Rep. Gr.34; Transmission Fluid; Transmission Fluid, Draining and Filling.

AWD Vehicles

Special tools and workshop equipment required

- Press Tool -T40323-

- Slide Hammer Set -VW771-

- Gearbox Assembly Tool -T40213 /1/2/3-

- Retaining Strap -T40155-

- Shop Crane -VAS6100-

- Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A-

Caution

Caution

Risk of damaging the transmission by mixing ATF and transmission fluid (MTF) through the same bleeder.

The ATF and transmission fluid must be drained.

Removing

- Draining the ATF. Refer to → Rep. Gr.34; ATF, Draining and Filling.

- Draining the transmission fluid. Refer to → Rep. Gr.34; Transmission Fluid, Draining and Filling.

- Remove the clutch. Refer to → Chapter "Dual Clutch, Removing and Installing".

- Turn the transmission on the Gearbox Support -T40206- 180º.

- Remove the differential.

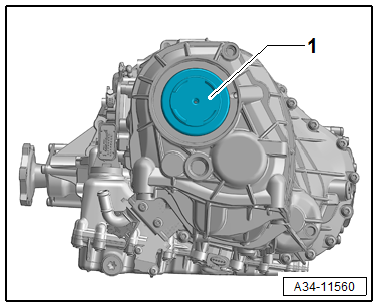

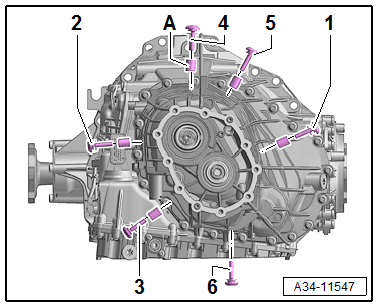

- Remove the oil catch tray -1-.

- Remove the circlip -1-.

- Remove the bolts for the transmission housing.

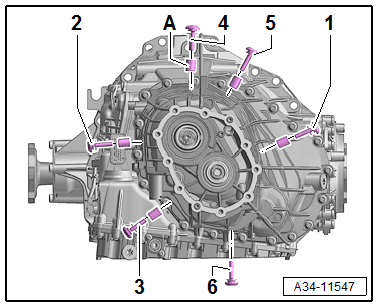

- Remove the bolts -1 to 6-.

- Remove the centering bushing -arrows- with the Slide Hammer Set -VW771-.

Note

Note

Bolt -6- without centering bushing.

- Remove the transmission housing with the Press Tool -T40323-.

- Prepare the 1/4 inch tool with Torx T30 and flexible extension as shown.

- Remove the bolts for the gear positioner -arrows-.

- Remove the bolt for the Transmission Input Speed Sensor 1 -G632--A- and remove the line from the oil pan -B-.

- Secure the Retaining Strap -T40155- on the gear set as shown and slowly and carefully remove with the Shop Crane -VAS6100- from the transmission housing.

- Pay attention to both needle bearings -arrows-.

- Loosen the bolts -arrow- for the hydraulic pressure reservoir but do not remove.

Note

Note

- If the hydraulic pressure reservoir lifts when loosening the bolts the ATF system is still under pressure.

- In this case the bolts from the Mechatronic must be minimally loosened to reduce the pressure in the ATF system via the sealing surfaces.

- Refer to → Chapter "ATF Pump, Deactivating and Draining the Hydraulic Pump Reservoir".

- Remove the bolts -arrows- and the hydraulic pressure reservoir.

- Remove the bolts -1 through 6- and remove the gear positioner module.

Installing

- Insert the gear positioner module and tighten the bolts in the sequence -1 to 6- hand-tight.

- Install the hydraulic pressure reservoir with new seals and tighten the bolts -arrow- hand-tight evenly.

- Tighten the gear positioner and pressure reservoir to the tightening specification. Refer to → Chapter "Overview - Gear Set, FWD Vehicles".

- Bring the gear positioner into the basic setting.

- Push the gear positioner by hand and turn at the same time it until it engages and determine the current backlash.

- Install the needle bearing -arrow-.

- Carefully remove the gear set.

- Guide together the bearing area and gear positioner -arrows- evenly.

- Install the needle bearing -arrow-.

- Install the gear positioner -arrows- hand-tight.

- When the gear positioner is installed correctly the dimension x must be approximately 2 mm.

- Tighten the bolts for the gear positioner to the tightening specification.

- Tighten the bolt -A- for the Transmission Input Speed Sensor 1 -G632- and install the line -B- in the oil pan.

- Install the Gearbox Assembly Tool -T40213A- on the transmission.

Note

Note

This step is necessity to that the bearing "E" in the transmission housing can be mounted correctly on the shaft.

- Install the spindle from the Gearbox Assembly Tool -T40213A- by hand only until the input shaft has raised 2 to 3 mm.

- Position the new seal and check if both centering pins are installed.

- Warm the inner race of the bearing "E"-arrow- with the Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A- to a maximum of 100 ºC (212 ºF).

- Guide together the transmission housing and the transmission.

- Install the new circlip -1- for the bearing "E".

Note

Note

- The circlip had different installed dimensions.

- If the bearing "E" is not replaced, a circlip with the same dimension as the old circlip must be installed.

- For a new bearing "E" the largest possible circlip to be installed must be used.

- Remove the Gearbox Assembly Tool -T40213A- from the transmission.

- Install the oil catch tray -1-.

- Tighten the transmission housing with new bolts. Tightening sequence and tightening specification. Refer to → Chapter "Overview - Transmission, FWD Vehicles".

- Press in the new end cover with the Press Tool -T40323-.

Caution

Caution

Oil loss due to improper assembly.

- The end cover is installed "dry" in the cleaned housing, never use locking agent.

- Let the end cover be tensioned 10 minutes with the Press Tool -T40323-.

- Install the connector with the Assembly Tool -T40305-.

- Install the clutch. Refer to → Chapter "Dual Clutch, Removing and Installing".

- Install the transmission fluid pan. Refer to → Chapter "Transmission Fluid Pan, Removing and Installing".

Hydraulic Pressure Reservoir, Disposing

Note

Note

- The installed hydraulic pressure reservoir is around a closed hollow body; that is impinged on by the prefilled working gas (nitrogen) with an inner pressure

- Because it is prohibited to scrap a closed hollow body, the hydraulic pressure reservoir must be drained before disposal.

- Remove the hydraulic pressure reservoir. Refer to → Chapter "Transmission, Disassembling and Assembling".

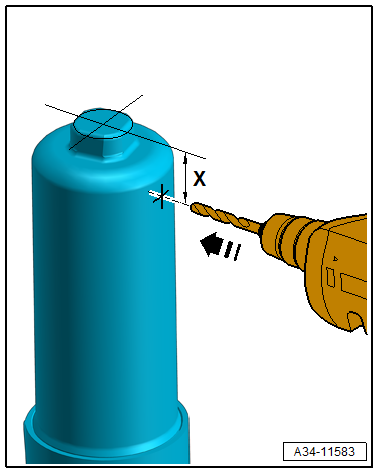

WARNING

WARNING

The system is under pressure.

- Wear protective eyewear and hearing protection when engaging the pressure reservoir.

- When the drill bit passes through in the gas space due to the internal pressure the shavings can be flung around.

- Tension the hydraulic pressure reservoir in the vise.

- Completely drill out approximately 25 mm -dimension x- from the square deck area with a 3 mm drill bit.

- The pressureless hydraulic pressure reservoir can then be scrapped.