Audi A4: Active Steering Safety Lock (Locking Solenoid), Removing and Installing

Special tools and workshop equipment required

- Vehicle Diagnostic Tester

- Torque Wrench 1783 - 2-10Nm -VAG1783-

Removing

Note

Note

- To avoid a crooked steering wheel, the steering wheel must not be turned and the straight-ahead position or angle of the front wheels must not be changed when the adjusting element is removed.

- Follow the guidelines for clean working conditions. Refer to → Chapter "Guidelines for Clean Working Conditions".

- Turn the steering wheel in the straight position.

- Switch off the ignition.

- Remove the driver side instrument panel cover. Refer to → Body Interior; Rep. Gr.68; Storage Compartments and Covers; Driver Side Instrument Panel Cover, Removing and Installing.

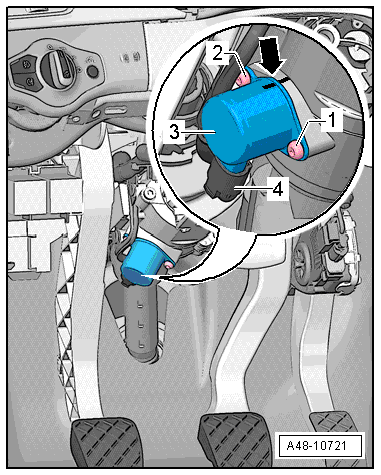

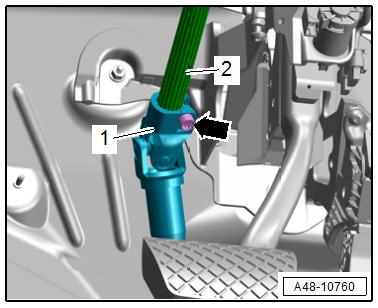

- Mark the installation position of the Active Steering Safety Lock Actuator -F437--arrow- for reinstallation.

- Disconnect the connector -4-.

- Clean paint residue off the bolt heads.

- Remove the bolts -1 and 2- (use the socket included in the repair kit), and remove the safety lock -3- from the steering column.

Installing

Install in reverse order of removal and note the following:

- Place the adjusting element according to the mark applied during removal and tighten (use the socket included in the repair kit). Refer to → Fig. "Active Steering Safety Lock (locking solenoid) - Tightening Specification and Sequence".

- Erase the DTC memory.

- Perform an initialization movement - turn 45º to the left/right away from the straight-ahead position.

Function Test

Check the function of the steering during the road test and a fenced off area.

- Operating force

- Reset

- Play

- Noise

- Indicator lamp

- Read the DTC memory after the road test. There must be no entries in the DTC memory.

Tightening Specifications

- Refer to → Fig. "Active Steering Safety Lock (locking solenoid) - Tightening Specification and Sequence"

Steering Intermediate Shaft, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Mandatory Replacement Parts

- Bolt - Steering Intermediate Shaft to Steering Gear

- Bolt - Steering wheel to Steering Column

Removing

- Bring wheels in the straight position.

- Move the driver seat all the way to the rear until it stops.

- Move the steering wheel as far to the rear and down as possible. Use the full steering column adjustment range for this.

- Switch off the ignition.

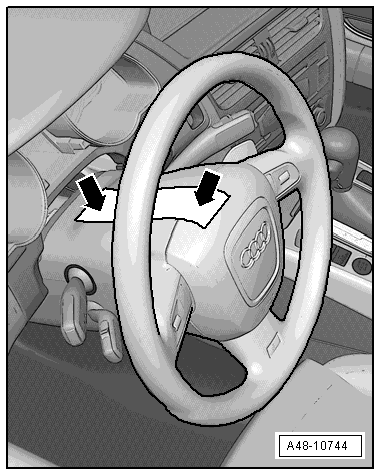

- Secure the steering wheel in the straight-ahead position using tape so that it does not turn unintentionally -arrow-.

Note

Note

- Use adhesive tape that can be removed without leaving any adhesive residue.

- Be careful not to turn the steering wheel during the repair because the Airbag Spiral Spring/Return Spring with Slip Ring -F138- can become damaged.

- Remove the rear noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

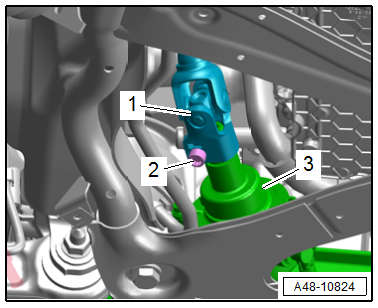

- Remove the bolt -2-.

- Remove the universal joint -1- for the steering intermediate shaft from the steering gear -3-.

- Remove the driver side footwell cover front section. Refer to → Body Interior; Rep. Gr.68; Storage Compartments and Covers; Driver Side Instrument Panel Cover, Removing and Installing.

- Remove the footrest. Refer to → Body Interior; Rep. Gr.70; Vehicle Interior Trim Panels; Footrest, Removing and Installing.

- Push the carpet slightly toward the rear.

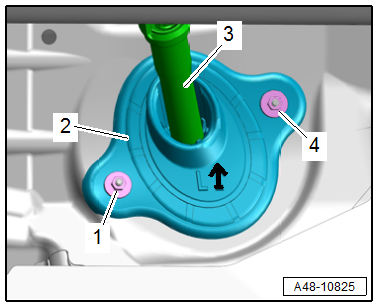

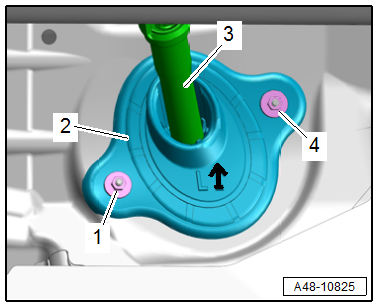

- Remove the nuts -1 and 4-, and remove the steering intermediate shaft -3- with the sealing lip -2-.

Note

Note

Ignore the -arrow-.

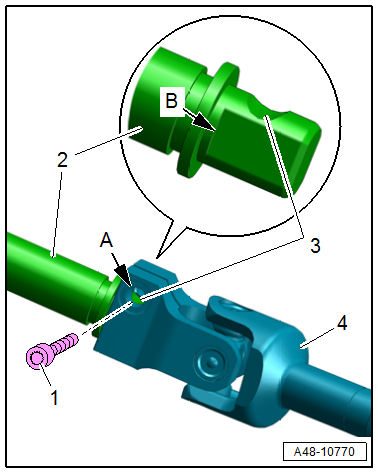

- Remove the bolt -arrow- and remove the steering intermediate shaft universal joint -1- from the steering column -2-.

- Remove the steering intermediate shaft.

Note

Note

The installation position pictured is for equipment versions without active steering.

Installing

Install in reverse order of removal and note the following:

Note

Note

- Replace the bolts after removing them.

- Clean the threaded holes for the bolts on the universal joint using a thread tap, for example.

- Bring the steering intermediate shaft -3- as shown into the installation position. The sealing lip -2- must rest on the insulation.

- The -arrow- points upward.

- Tighten the nuts -1 and 4-.

WARNING

WARNING

There is a risk of accident due to an absence of traction if the steering intermediate shaft is installed incorrectly.

Pay attention to the installation position and installation instructions.

- Install the steering intermediate shaft universal joint -4- up to the stop -arrow B- on the steering column -2- or steering gear.

- The opening -3- on the steering column or steering gear must align exactly with the hole -arrow A- for the bolt -1- on the universal joint as shown.

- Install the new bolt all the way by hand.

- Check if the steering intermediate shaft is seated correctly by pulling. Tighten the bolt.

- Repeat the procedure on the lower universal joint to the steering gear.

- Readapting the end position of the steering gear. Refer to → Chapter "Steering Gear End Positions, Adapting".

Tightening Specifications

- Refer to → Chapter "Overview - Steering Column"

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.