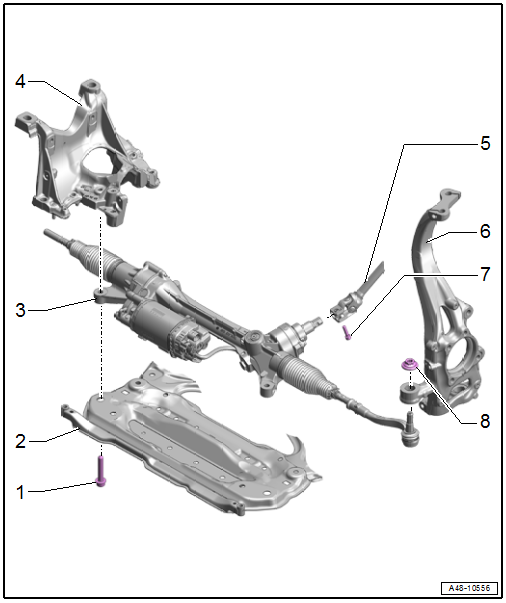

Audi A4: Overview - Steering Gear

Audi A4 (B9) 2016-2026 Service Manual / Chassis / Steering / Steering Gear / Overview - Steering Gear

Overview - Steering Gear

1 - Bolt

- Replace after removing

- Tightening specification -Item 2-

2 - Subframe Crossbrace

- Overview. Refer to → Chapter "Overview - Subframe".

3 - Steering Gear with Tie Rods

- With integrated Power Steering Control Module -J500-

- the Power Steering Control Module -J500- cannot be replaced separately

- Replace the steering gear if faulty

- Removing and installing. Refer to → Chapter "Steering Gear, Removing and Installing".

- Servicing. Refer to → Chapter "Overview - Steering Gear, Tie Rods".

4 - Subframe

- Overview. Refer to → Chapter "Overview - Subframe".

5 - Steering Intermediate Shaft

- Removing and installing. Refer to → Chapter "Steering Intermediate Shaft, Removing and Installing".

6 - Wheel Bearing Housing

- Overview. Refer to → Chapter "Overview - Wheel Bearing".

7 - Bolt

- Tightening specification -Item 1-

8 - Nut

- 140 Nm

- Replace after removing

- Remove the adhesive residue from the pin threads after removing

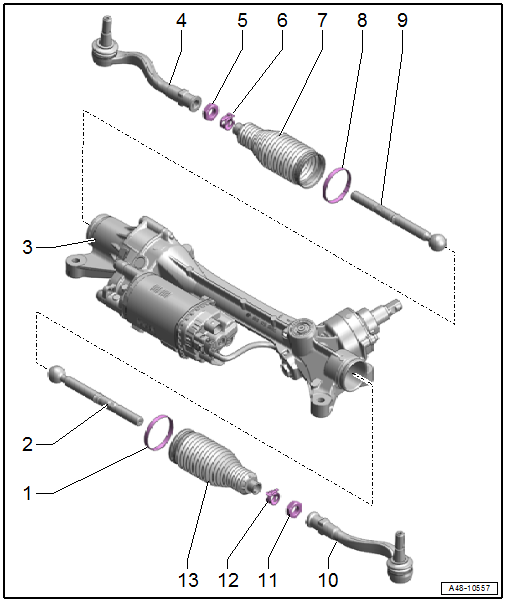

Overview - Steering Gear, Tie Rods

1 - Clamp

- Replace after removing

- Do not open the new clamp

- Tensioning.

2 - Tie Rod

- 140 Nm

- Grease the joint with Steering Gear Grease -G 052 168 A1-

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing".

3 - Steering Gear

- Grease the steering rack with Steering Gear Grease -G 052 168 A1-

- Removing and installing. Refer to → Chapter "Steering Gear, Removing and Installing".

4 - Tie Rod End

- Check dust cap for damage and correct seating.

- Check dimension. Refer to → Fig. "Tie Rod End Check Dimension"

- Removing and installing. Refer to → Chapter "Tie Rod End, Removing and Installing".

5 - Nut

- 80 Nm

- When loosening and tightening, counterhold at the tie rod end

6 - Spring Clamp

- Replace after removing

- Spring clamp, installing.

7 - Boot

- Check for damage

- Replace after removing

- Must not be twisted when toe is being adjusted

- Grease the sealing locations with Steering Gear Grease -G 052 168 A1-

- Replacing. Refer to → Chapter "Boot, Removing and Installing".

8 - Clamp

- Replace after removing

- Do not open the new clamp

- Tensioning. Refer to → Fig. "Tighten the Inner Clamp using the Locking Pliers -VAS6199-".

9 - Tie Rod

- 140 Nm

- Grease the joint with Steering Gear Grease -G 052 168 A1-

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing".

10 - Tie Rod End

- Check dust cap for damage and correct seating.

- Check dimension. Refer to → Fig. "Tie Rod End Check Dimension"

- Removing and installing. Refer to → Chapter "Tie Rod End, Removing and Installing".

11 - Nut

- 80 Nm

- When loosening and tightening, counterhold at the tie rod end

12 - Spring Clamp

- Replace after removing

- Spring clamp, installing. Refer to → Fig. "Outer Boot Installation Position".

13 - Boot

- Check for damage

- Replace after removing

- Must not be twisted when toe is being adjusted

- Grease the sealing locations with Steering Gear Grease -G 052 168 A1-

- Installation position. Refer to → Fig. "Outer Boot Installation Position".

- Replacing. Refer to → Chapter "Boot, Removing and Installing".

READ NEXT:

Steering Gear, Removing and Installing

Steering Gear, Removing and Installing

Special tools and workshop equipment required

Torque Wrench 1331 5-50Nm -VAG1331-

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Ball Joint Splitter -VAS251805-, not illu

Boot, Removing and Installing

Boot, Removing and Installing

Special tools and workshop equipment required

Torque Wrench 1331 5-50Nm -VAG1331-

Hose Clip Pliers -VAS6362-

Hose Clip Pliers -VAG1921-

Caution

This procedure contains mandatory replacea

Tie Rod, Removing and Installing

Tie Rod, Removing and Installing

Special tools and workshop equipment required

Torque Wrench 1332 40-200Nm -VAG1332-

Torque Wrench Insert - Open Jaw -VAG1923-

Caution

This procedure contains mandatory replaceable parts.

SEE MORE:

Battery Charger -VAS5903- Support Mode

Battery Charger -VAS5903- Support Mode

General Information

The support mode provides the vehicle electrical system with

voltage when the Battery -A- is removed or disconnected.

For more information. Refer to the Battery Charger -VAS5903-

Operating Instructions.

The support mode is used for the following situations:

Vehicle electrical

Rearview Camera -R189-, Removing and Installing

Rearview Camera -R189-, Removing and Installing

Rearview Camera -R189-, Removing and Installing, Sedan

The Rearview Camera -R189- is inside the rear lid handle

button. It permanently attached to the handle button.

If the Rearview Camera -R189- must be replaced, then the

handle button must also be replaced.

Removing

- Turn off the ignition

© 2019-2026 Copyright www.audia4b9.com