Audi A4: Engine, Installing

Special tools and workshop equipment required

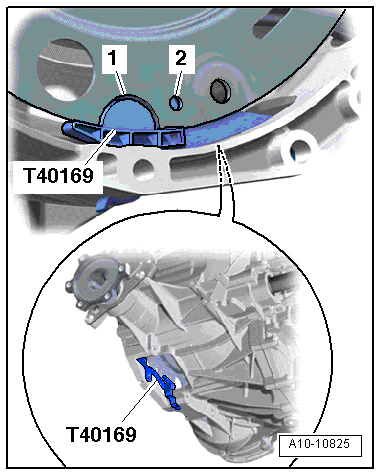

- Clutch Module Assembly Aid -T40169-

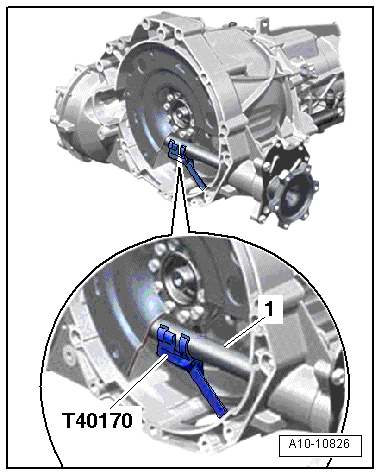

- Clutch Module Transportation Lock -T40170-

- as well as when removing with listed special tools

- Engine Support Bridge - Spindle -10-222A/11-

- Shop Crane -VAS6100-

- Engine Sling -2024A-

- Torque Wrench 1332 Insert - Ring Wrench - 16mm -VAG1332/14-

- Wrench - 21mm -T40263-,

- Adapter -T40314-

Tightening Specifications

Note

Note

- The tightening specifications only apply to lightly greased, oiled, phosphated or blackened nuts and bolts.

- Additional lubricants, such as engine or transmission oil are permissible, although lubricants containing graphite are not.

- Do not use any ungreased parts.

- Tightening specification tolerance: +-15%.

.png)

- Refer to → Chapter "Overview - Subframe Mount"

- Engine to transmission. Refer to → Transmission; Rep. Gr.34; Transmission, Removing and Installing; Transmission Tightening Specifications.

Procedure

Note

Note

- Replace the bolts that were tightened with an additional turn after removing them.

- Replace the self-locking nuts and bolts, gaskets, seals and O-rings after removing.

- In the drive plate on vehicles with a manual transmission a needle bearing is installed. Refer to → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.13; Transmission Side Cylinder Block; Needle Bearing in Drive Plate, Replacing.

- The hose connections and charge air system hoses must be free of oil and grease before installing.

- Secure all hose connections with hose clamps that match the ones used in series production. Refer to the Parts Catalog.

- To mount the charge air hoses on their connectors securely, spray the bolts on the used clamps with rust remover before installing.

- During installation, all cable ties must be installed at the same location.

- The following preparations must be made before connecting the engine and transmission:

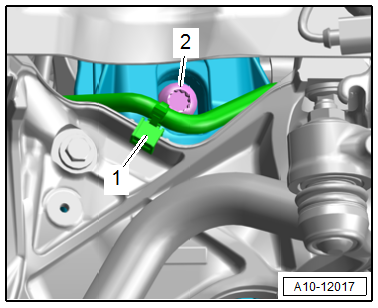

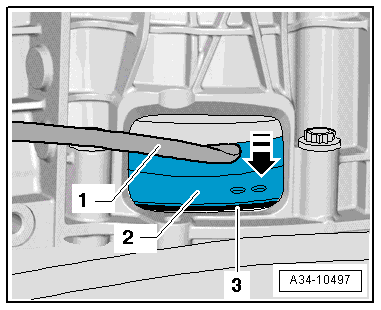

- Insert the -T40169- in the transmission housing and the flywheel from below as shown.

- The assembly aid must engage in the semicircular opening -1- and in the check hole -2-.

Note

Note

There is only one inspection opening on the circumference so rotate the flywheel as needed.

- Install the assembly aid pin into the hole on the transmission housing.

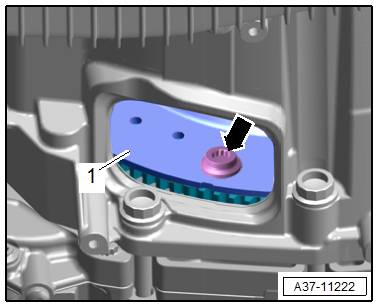

- Insert the -T40170- in the transmission housing from below and secure it on the flange shaft -1-.

Note

Note

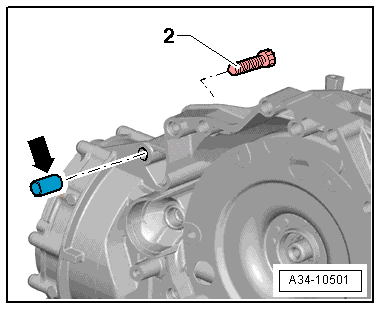

- The bolt -2- attaches the starter to the transmission and has an additional spacer sleeve -arrow-.

- The spacer sleeve must be inserted between the starter and the transmission.

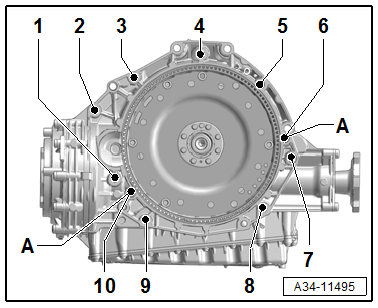

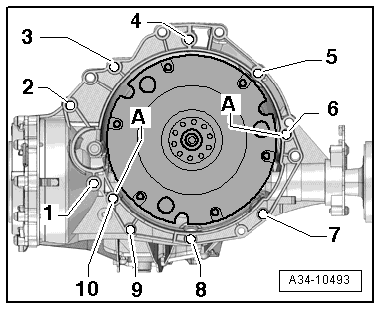

Vehicle with Manual Transmission

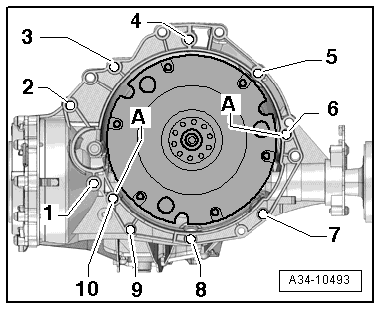

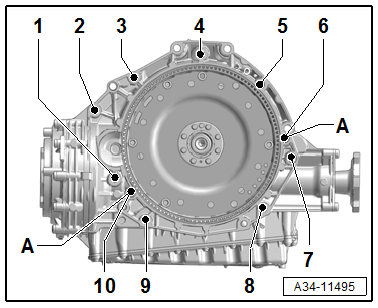

- Check if the alignment sleeves -A- for centering the engine and transmission in the cylinder block are installed.

- Inspect the aluminum bolts used to connect the engine to the transmission to check if they can be used again and mark them if necessary. Refer to → Transmission; Rep. Gr.34; Transmission, Removing and Installing; Transmission Tightening Specifications.

- Position the transmission on the engine and tighten the bolts -3 through 5-. Tightening specifications. Refer to → Transmission; Rep. Gr.34; Transmission, Removing and Installing; Transmission Tightening Specifications.

Vehicle with Dual-Clutch Transmission

- Check if the alignment sleeves -A- for centering the engine and transmission in the cylinder block are installed.

- Inspect the aluminum bolts used to connect the engine to the transmission to check if they can be used again and mark them if necessary. Refer to → Transmission; Rep. Gr.34; Transmission, Removing and Installing; Transmission Tightening Specifications.

- Position the transmission on the engine and tighten the bolts -3 through 5-. Tightening specifications. Refer to → Transmission; Rep. Gr.34; Transmission, Removing and Installing; Transmission Tightening Specifications.

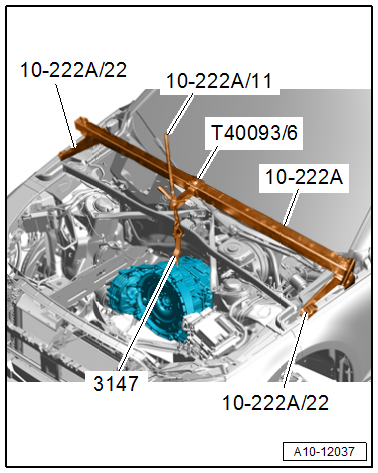

Continuation for All Vehicles

- Release the tension on the -10-222A/11-.

- Lower the workshop crane and mount the engine and transmission onto the engine mount.

- Tighten the left and right bolts -2- for the engine mount.

Note

Note

Ignore item -1-.

- Remove the -VAS6100- and -2024A-.

Vehicle with Manual Transmission

- Tighten the bolts -6 through 10-. Refer to → Transmission; Rep. Gr.34; Transmission, Removing and Installing; Transmission Tightening Specifications.

Vehicle with Dual-Clutch Transmission

- Tighten the bolts -6 through 10-. Refer to → Transmission; Rep. Gr.34; Transmission, Removing and Installing; Transmission Tightening Specifications.

Continuation for All Vehicles

- Remove the -T40170- and -T40169-.

Note

Note

The following procedure is necessary to assure that the flywheel contacts the drive plate evenly and does not get bent.

- Press the flywheel -2- slightly in against the drive plate -3- using an assembly lever -1--arrow-.

- Secure the flywheel -1- to the drive plate as follows:

Note

Note

Use the -VAG1332/14- to tighten the bolts.

- First install the bolt -arrow- to 10 Nm and then loosen and tighten again to 2 Nm (hand-tight).

Caution

Caution

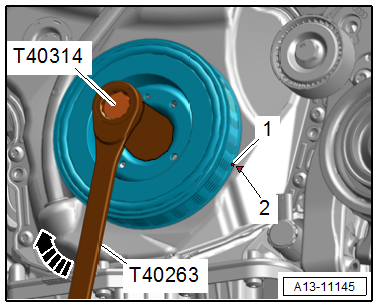

Risk of destroying the engine by skipping the camshaft timing chain.

Turn the crankshaft only in direction of engine rotation -arrow-.

- Turn the crankshaft with -T40263-, -T40314- and a 24 mm socket 120º in the direction of engine rotation.

Note

Note

Ignore items -1 and 2-.

- In this crankshaft stub tighten the next bolt. Refer to → Manual Transmission; Rep. Gr.30; Clutch; Overview - Clutch Module or → Direct Shift Gearbox; Rep. Gr.34; Transmission, Removing and Installing; Transmission Tightening Specifications.

- Install the crankshaft 120º in the direction of engine rotation and tighten the next bolt.

- Install the crankshaft 120º in the direction of engine rotation and tighten the last bolt.

Further installation is performed in reverse order of removal, while noting the following:

- Install the starter. Refer to → Electrical Equipment; Rep. Gr.27; Starter; Starter, Removing and Installing.

- Connect the fuel hose. Refer to → Fuel Supply System; Rep. Gr.20; Connector Couplings; Connector Couplings, Disconnecting.

- Install the Heated Oxygen Sensor -G39-. Refer to → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.24; Heated Oxygen Sensor; Heated Oxygen Sensor, Removing and Installing.

- Tighten the drive axle. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Driveshaft; Driveshaft, Removing and Installing.

- Install the drive axle heat shield. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Driveshaft; Driveshaft Heat Shield, Removing and Installing.

- Install the A/C compressor. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; A/C Compressor; A/C Compressor, Removing and Installing from Bracket.

- Install the ribbed belt. Refer to → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.13; Cylinder Block Belt Pulley Side; Ribbed Belt Tensioner, Removing and Installing.

- Install the air filter housing. Refer to → Chapter "Air Filter Housing, Removing and Installing".

- Connections and wire routing. Refer to → Wiring diagrams, Troubleshooting & Component locations.

- Install the catalytic converter. Refer to → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.26; Emissions Control System; Catalytic Converter, Removing and Installing.

- Install the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

- Install the engine cover. Refer to → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.10; Engine Cover; Engine Cover, Removing and Installing.

- Fill with engine oil or check the oil level.

- Follow all steps after connecting the battery. Refer to → Electrical Equipment; Rep. Gr.27; Battery; Battery, Disconnecting and Connecting.

Caution

Caution

There is a risk of destroying the control modules due to excessive voltage.

Do not use a charger to jump start.

- If the engine is replaced, perform the "01 - mechanical engine, functions" listed adaptation using the Vehicle Diagnostic Tester.

Caution

Caution

Risk of component damage.

Perform the additional adaptation for each component, that was replaced at the same time.

- Connect the coolant hose to the connector coupling. Refer to → Fig. "Connect the Coolant Hose to the Connector Coupling".

Note

Note

Used coolant cannot be used again.

- Fill with coolant. Refer to → Chapter "Coolant, Draining and Filling".

- Install the wheel housing liners and wheel spoiler. Refer to → Body Exterior; Rep. Gr.66; Wheel Housing Liner; Overview - Front Wheel Housing Liner.

- Install the front wheels. Refer to → Suspension, Wheels, Steering; Rep. Gr.44; Wheels, Tires.

- Install the noise insulations. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.