Audi A4: Overview - Gear Set

Audi A4 (B9) 2016-2026 Service Manual / Transmission / Servicing - 7-Speed Dual Clutch Transmission 0CJ, 0CL, 0CK / Controls, Housing / Overview - Gear Set

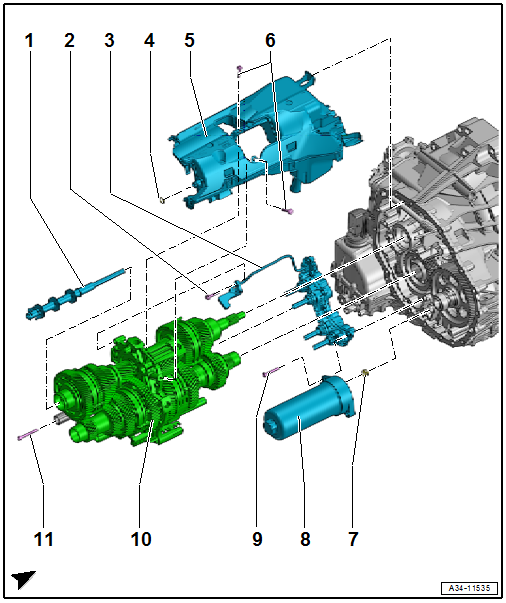

Overview - Gear Set, FWD Vehicles

1 - Oil Pipe

2 - Bolt

- 3 Nm + 90Âş

- Replacing

- M6 Ă— 30

3 - Gear Positioner with:

- Transmission Input Speed Sensor 1 -G632-

- Transmission Input Speed Sensor 2 -G612-

- Gear Position Distance Sensor 1 -G487-

- Gear Position Distance Sensor 2 -G488-

- Gear Position Distance Sensor 3 -G489-

- Gear Position Distance Sensor 4 -G490-

- Removing an installing. Refer to → Chapter "Transmission, Disassembling and Assembling".

4 - Seal

- Replacing

5 - Oil Pan

- Replacing

6 - Bolt

- 3 Nm + 90Âş

- Replacing

- M6 Ă— 30

7 - Seal

- Replacing

8 - Hydraulic Pressure Reservoir

- Observe the safety notes. Refer to → Chapter "ATF Pump, Deactivating and Draining the Hydraulic Pump Reservoir".

- Removing an installing. Refer to → Chapter "Transmission, Disassembling and Assembling".

- Disposal. Refer to → Chapter "Hydraulic Pressure Reservoir, Disposing".

9 - Bolts

- 3 Nm + 90Âş

- Replacing

- M6 Ă— 30

10 - Gear Set

- Removing and installing. Refer to → Chapter "Transmission, Disassembling and Assembling".

11 - Bolts

- 6 Nm + 30Âş

- Gearshift rail gear positioner module

- M6 Ă— 50

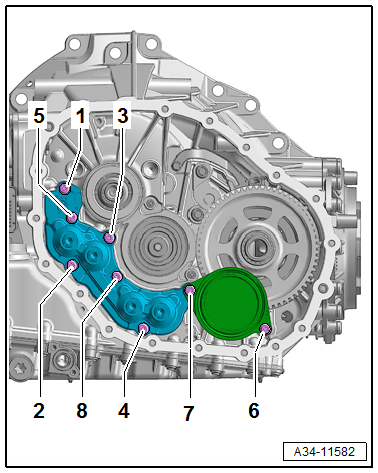

Gear Positioner and Pressure Reservoir Tightening Sequence

Note

Note

Replace the bolts.

- Tighten the bolts in two steps in the sequence shown:

.png)

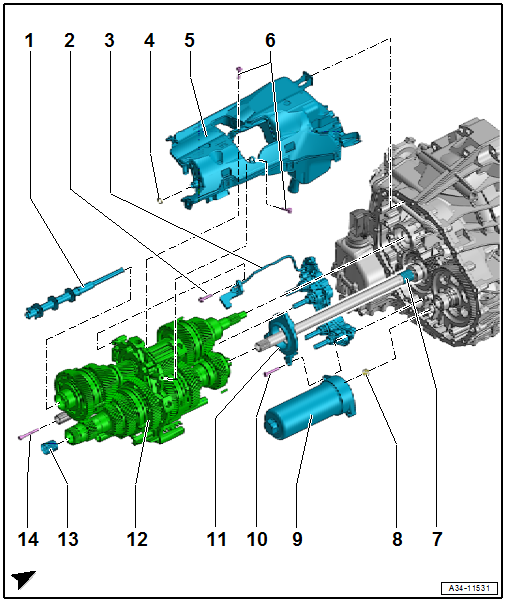

Overview - Gear Set, AWD Vehicles

1 - Oil Pipe

2 - Bolt

- 3 Nm + 90Âş

- Replacing

- M6 Ă— 30

3 - Gear Positioner with:

- Transmission Input Speed Sensor 1 -G632-

- Transmission Input Speed Sensor 2 -G612-

- Gear Position Distance Sensor 1 -G487-

- Gear Position Distance Sensor 2 -G488-

- Gear Position Distance Sensor 3 -G489-

- Gear Position Distance Sensor 4 -G490-

- Removing an installing. Refer to → Chapter "Transmission, Disassembling and Assembling".

- Observe the tightening sequence. Refer to → Fig. "Gear Positioner, Pressure Reservoir and Gear Carrier Tightening Sequence".

4 - Seal

- Replacing

5 - Oil Pan

- Replacing

6 - Bolts

- 3 Nm + 90Âş

- Replacing

- M6 Ă— 30

7 - Needle Bearing

8 - Seal

- Replacing

9 - Hydraulic Pressure Reservoir

- Observe the safety notes. Refer to → Chapter "ATF Pump, Deactivating and Draining the Hydraulic Pump Reservoir".

- Removing an installing. Refer to → Chapter "Transmission, Disassembling and Assembling".

- Disposal. Refer to → Chapter "Hydraulic Pressure Reservoir, Disposing".

- Observe the tightening sequence. Refer to → Fig. "Gear Positioner, Pressure Reservoir and Gear Carrier Tightening Sequence".

10 - Bolts

- Replacing

- Observe the tightening sequence. Refer to → Fig. "Gear Positioner, Pressure Reservoir and Gear Carrier Tightening Sequence".

11 - Bearing Bracket with Roller Bearing

- Observe the tightening sequence. Refer to → Fig. "Gear Positioner, Pressure Reservoir and Gear Carrier Tightening Sequence".

12 - Gear Set

- Removing and installing. Refer to → Chapter "Transmission, Disassembling and Assembling".

13 - Needle Bearing

14 - Bolts

- 6 Nm + 30Âş

- Gearshift rail gear positioner module

- M6 Ă— 50

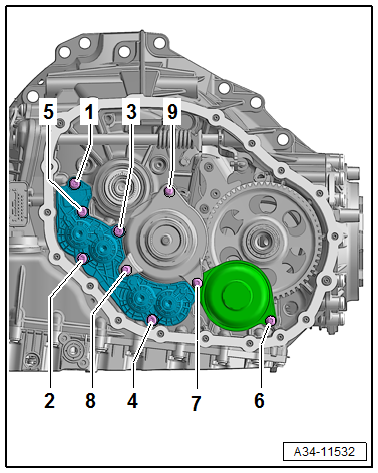

Gear Positioner, Pressure Reservoir and Gear Carrier Tightening Sequence

- Tighten the bolts in four steps in the sequence shown:

.png)

READ NEXT:

Transmission, Disassembling and Assembling

Transmission, Disassembling and Assembling

WARNING

The system is under pressure.

The electronic ATF pump must be deactivated every

time before opening the transmission, and the hydraulic

pressure reservoir is drained.

Refer to

â

Transmission Fluid Circuit

Transmission Fluid Circuit

Overview - Transmission Fluid Circuit

1 - Plug

8 Nm +30Âş

Replace after removing.

For the ATF check and fill hole

2 - Plug

35 Nm

Replace after removing.

For transmission

DSG Transmission Mechatronic -J743-

DSG Transmission Mechatronic -J743-

Overview - Mechatronic

1 - Transmission Fluid Pan

Removing and installing. Refer to

→ Chapter "Transmission Fluid Pan, Removing and Installing".

2 - Bolt

Tightenin

SEE MORE:

Need for Axle Alignment, Evaluating

Need for Axle Alignment, Evaluating

A wheel alignment is necessary if:

Vehicle shows handling problems.

Involved in an accident.

If axle components were removed and installed or replaced.

Tire wear patterns are uneven.

After REMOVING and REINSTALLING components.

1) When the subframe crossbrace

was secured with the locating p

Engine, Removing

Engine, Removing

Special tools and workshop equipment required

Engine Support Bridge -10-222A-

Engine Sling -2024A-

Engine Support Bridge Adapter -3147-

Ring Wrench 7-Piece Set -3337-

Torque Wrench 1332 Insert - Ring Wrench - 16mm -VAG1332/14-

Shop Crane -VAS6100-

Engine Bung Set -VAS6122-

Coolant Collectio

© 2019-2026 Copyright www.audia4b9.com