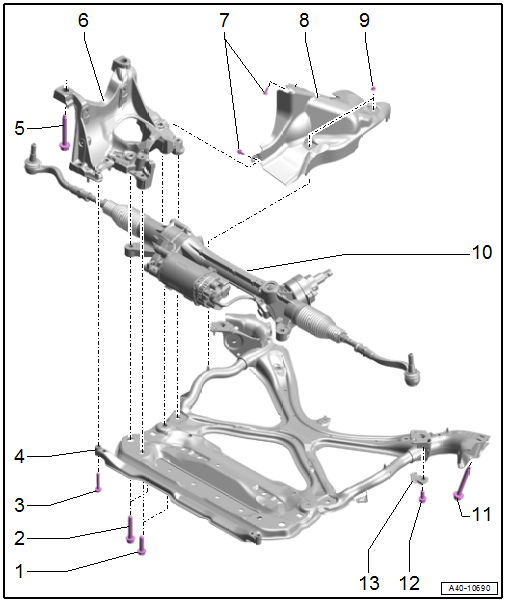

Audi A4: Overview - Subframe

Subframe

Caution

Caution

There is a risk of damaging the threads on the subframe threaded connection to the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

There is a risk of damaging the suspension components.

- If the subframe mount, steering gear or subframe crossbrace are not installed correctly, do not rest the vehicle on its wheels.

- Supporting the vehicle at the subframe or the subframe crossbrace (for example, using a floor jack or similar device) is not permitted.

1 - Bolt

- 90 Nm +90º

- Replace after removing

2 - Fitting Bolt

- 90 Nm +90º

- Replace after removing

3 - Bolt

- 30 Nm

4 - Subframe Crossbrace

- Removing and installing. Refer to → Chapter "Subframe Crossbrace, Removing and Installing".

5 - Bolt

- 115 Nm + 180º

- Replace after removing

- Loosen and tighten together with -Item 11- → Item and -Item 12- → Item diagonally in stages

6 - Subframe

- Securing. Refer to → Chapter "Subframe, Securing".

- Lowering. Refer to → Chapter "Subframe, Lowering".

- Removing and installing. Refer to → Chapter "Subframe with Steering Gear, Removing and Installing".

7 - Bolts

- 9 Nm

8 - Shield

- Removing and installing. Refer to → Chapter "Subframe Shield, Removing and Installing".

9 - Nut

- 9 Nm

10 - Steering Gear

- Overview. Refer to → Chapter "Overview - Steering Gear".

11 - Bolt

- 115 Nm + 180º

- Replace after removing

- Loosen and tighten together with -Item 5- and -Item 12- → Item diagonally in stages

12 - Bolt

- 50 Nm + 90º

- Replace after removing

- Loosen and tighten together with -Item 5- and -Item 11- → Item diagonally in stages

13 - Clip

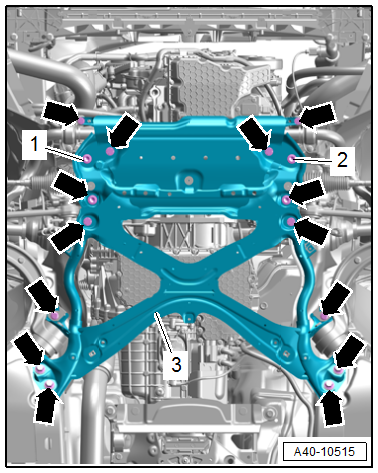

Subframe Crossbrace - Tightening Sequence

- Tighten the bolts in the steps shown in the sequence:

.png)

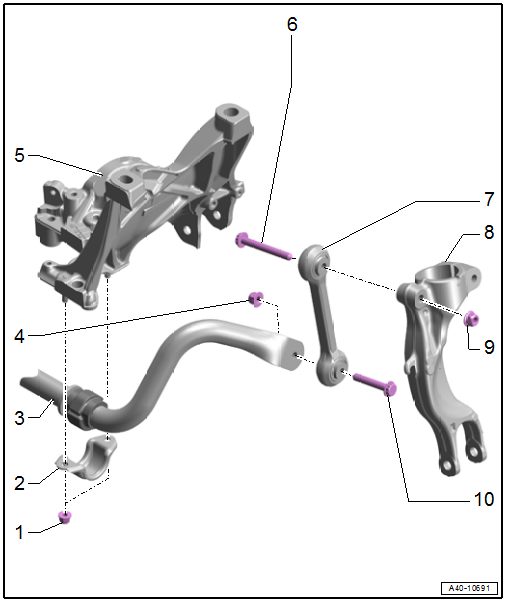

Stabilizer Bar

1 - Nut

- 30 Nm

- Replace after removing

- Remove and tighten evenly alternating from side to side.

2 - Clamp

3 - Stabilizer Bar

- With rubber bushing

- The rubber bushing cannot be replaced separately

- Removing and installing. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

4 - Nut

- 40 Nm + 90º

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

5 - Subframe

6 - Bolt

- Replace after removing

7 - Coupling Rod

- Removing and installing. Refer to → Chapter "Coupling Rod, Removing and Installing".

8 - Shock Absorber Fork

- Removing and installing. Refer to → Chapter "Shock Absorber Fork, Removing and Installing".

9 - Nut

- 40 Nm + 90º

- Replace after removing

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

10 - Bolt

- Replace after removing

READ NEXT:

Subframe, Securing

Subframe, Securing

Special tools and workshop equipment required

Torque Wrench 1331 5-50Nm -VAG1331-

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Gearbox Support -T40173-

Locating Pins -

Subframe, Lowering

Subframe, Lowering

Special tools and workshop equipment required

Torque Wrench 1331 5-50Nm -VAG1331-

Torque Wrench 1332 40-200Nm -VAG1332-

Tensioning Straps -T10038-

Engine and Gearbox Jack -VAS6931-

Locating Pins

Subframe with Steering Gear, Removing and Installing

Subframe with Steering Gear, Removing and Installing

Special tools and workshop equipment required

Torque Wrench 1331 5-50Nm -VAG1331-

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Ball Joint Splitter -VAS251805-, not illu

SEE MORE:

Tires and vehicle load limits

Tires and vehicle load limits

There are limits to the amount of

load or weight that any vehicle

and any tire can carry. A vehicle

that is overloaded will not handle well and is more difficult to stop.

Overloading can not only lead to

loss of vehicle control, but can also

damage important parts of the

vehicle and can lead to sudd

Special Tools

Special Tools

Special tools and workshop equipment required

Analog/Digital Multimeter -FLU83III-

Puller - Bevel Gear -T10474-

Torque Wrench 1332 40-200Nm -VAG1332-

Inner Hex Socket 8 mm or TORX T50

Battery Charger -VAS5095A-

Battery Tester with Printer -VAS5097A-

Battery Charger -VAS5900-

© 2019-2026 Copyright www.audia4b9.com