Audi A4: Wheel Bearing Housing, Removing and Installing

Special tools and workshop equipment required

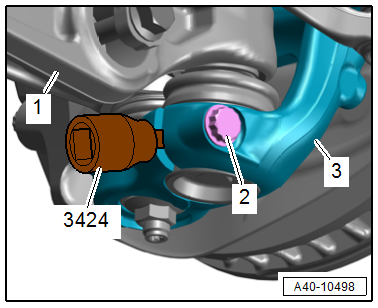

- Spreader Tool -3424-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

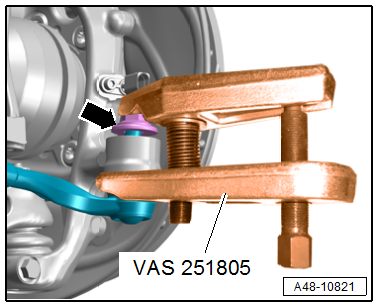

- Ball Joint Splitter -VAS251805-, not illustrated

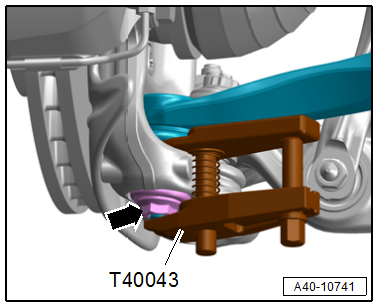

- Puller - Ball Joint -T40043-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Mandatory Replacement Parts

- Bolt - Ball Joint to Wheel Bearing Housing

- Nut - Ball Joint to Control Arm

Removing

- Loosen the connection between the drive axle and wheel hub. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

- Remove the front speed sensor and free up the wire. Refer to → Brake System; Rep. Gr.45; Sensors; Right/Left Front ABS Wheel Speed Sensor G45/G47, Removing and Installing.

- Remove the brake caliper. Refer to → Brake System; Rep. Gr.46; Front Brakes; Brake Caliper, Removing and Installing.

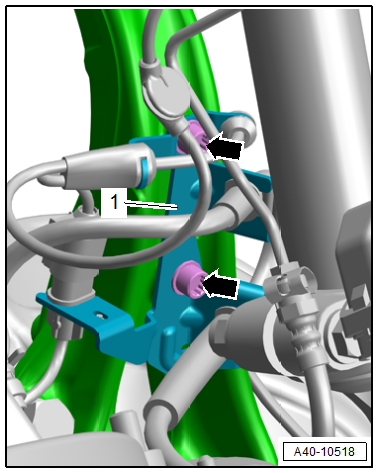

- Remove the bolts -arrows-, and move the bracket -1- to the side.

- To protect the threads, remove the nut -arrow- from the tie rod end joint pin until it is flush with the joint pin threads.

WARNING

WARNING

There is a risk of injury from falling components.

When pressing off, the tie rod end loosens abruptly from the wheel bearing housing. Use, for example, the -VAS6931- to secure.

Caution

Caution

There is a risk of damaging the ball joint puller.

Make sure that both puller lever arms are parallel to each other when using maximum force.

- Remove the tie rod end with the -VAS251805- from the wheel bearing housing.

- Then remove the nut. Use a 6 mm inner hex socket to counterhold at the joint pin if necessary.

- To protect the threads, remove the nut -arrow- on the guide link joint pin until it is flush with the joint pin threads. If necessary counterhold the joint pin.

WARNING

WARNING

There is a risk of injury from falling components.

When pressing off, the ball joint loosens abruptly from the wheel bearing housing. Use, for example, the -VAS6931- to secure.

- Press out the guide link joint pin with the -T40043- from the conical seat. Do not damage the CV boot while doing so.

- Remove the nut and free up the guide link on the wheel bearing housing. If necessary, counterhold the joint pin with a TX 40 socket to do this.

WARNING

WARNING

There is an accident risk due to the weight of the wheel bearing housing.

A second technician is required to remove the wheel bearing housing.

Caution

Caution

There is a risk of damaging the wheel bearing housing.

The slits in the wheel bearing housing must not be widened using a chisel or similar tool!

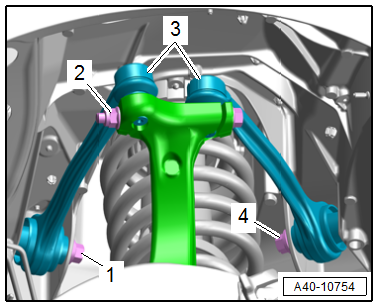

- Disconnect the threaded connection -2-.

- Remove the joint pins for the upper control arm -3- from the wheel bearing housing.

Note

Note

Ignore items -1 and 4-.

- Remove the bolt -2-.

- Insert the -3424- into the slit on the wheel bearing housing -3- and turn 90º.

- Pull the wheel bearing housing downward from the ball joint and remove it.

- Tie up the drive axle.

Note

Note

- The drive axle must not hang down, otherwise the inner joint will be damaged by over bending.

- Ignore item -1-.

Installing

Install in reverse order of removal and note the following:

- Slide the wheel bearing housing onto the drive axle splines.

- Install the control arm. Refer to → Chapter "Control Arm, Removing and Installing".

- Install the upper control arm. Refer to → Chapter "Upper Control Arm, Removing and Installing".

- Tighten the threaded connection between the drive axle and wheel hub. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

- Overview table for when an axle alignment is needed. Refer to → Chapter "Need for Axle Alignment, Evaluating".

Tightening Specifications

- Refer to → Chapter "Overview - Wheel Bearing"

- Refer to → Chapter "Overview - Lower Control Arm and Ball Joint"

- Refer to → Brake System; Rep. Gr.45; Sensors; Overview - Front Axle Speed Sensor.