Audi A4: Engine, Removing

Special tools and workshop equipment required

- Engine Support Bridge -10-222A-

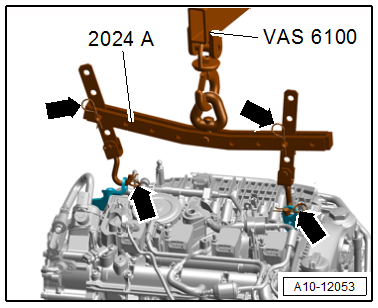

- Engine Sling -2024A-

- Engine Support Bridge Adapter -3147-

- Ring Wrench 7-Piece Set -3337-

- Torque Wrench 1332 Insert - Ring Wrench - 16mm -VAG1332/14-

- Shop Crane -VAS6100-

- Engine Bung Set -VAS6122-

- Coolant Collection System -VAS5014- or Shop Crane - Drip Tray -VAS6208-

- Hose Clip Pliers -VAS6362-

- Torque Wrench Adapter -VAS6948-

- Locking Pin -T10060A-

- Engine Support - Supplement Kit - Adapter -T40093/6- from the Engine Support - Supplement Kit -T40093A-

- Wrench - 21mm -T40263-

- Adapter -T40314-

- Engine Support Bridge - Spindle -10-222A/11-

- Engine Support Bridge - Sub-Frame Adapter -10-222A/22-

- Engine Support Bridge Adapter -3147-

Procedure

Note

Note

- Remove the engine upward without the transmission.

- During installation, all cable ties must be installed at the same location.

Caution

Caution

There is a risk of destroying electronic components when disconnecting the battery.

Follow the steps for disconnecting the battery.

- Disconnect the battery. Refer to → Electrical Equipment; Rep. Gr.27; Battery; Battery, Disconnecting and Connecting.

- On versions with a manual transmission engage the 4th gear.

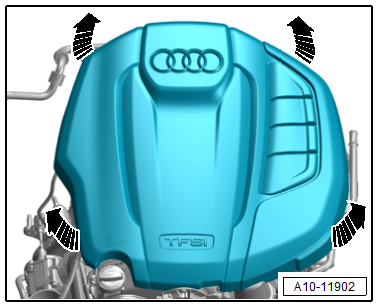

- Carefully pull the engine cover off the retaining pins one after the other in the direction of -arrows-. Do not pull sharply on the engine cover or pull it to one side.

WARNING

WARNING

Risk of scalding due to hot coolant.

Pay attention to the safety precautions. Refer to → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.00; Safety Instructions; Safety Precautions when Working the Cooling System.

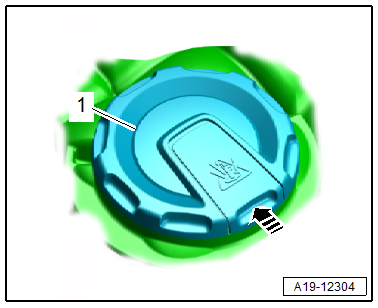

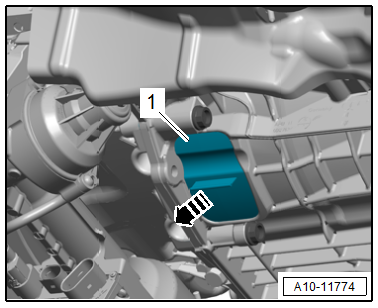

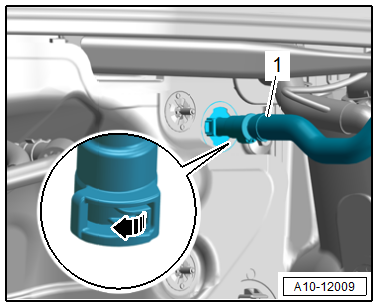

- Open the cover -1- for the coolant expansion tank by releasing the catch in the direction of -arrow-.

- Remove the front wheels. Refer to → Suspension, Wheels, Steering; Rep. Gr.44; Wheels, Tires.

- Remove the noise insulations. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

- Remove the left and right wheel spoiler as well as the right front wheel housing liner. Refer to → Body Exterior; Rep. Gr.66; Wheel Housing Liner; Front Wheel Housing Liner, Removing and Installing.

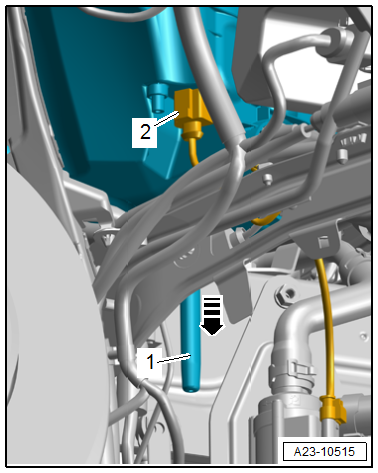

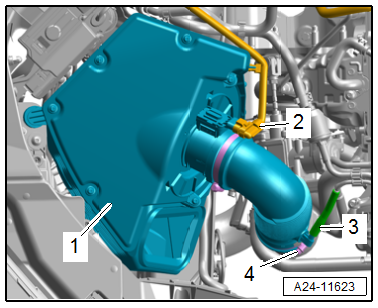

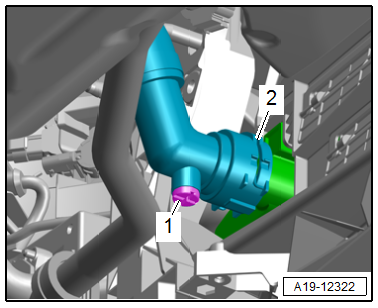

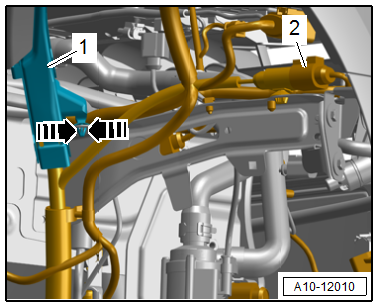

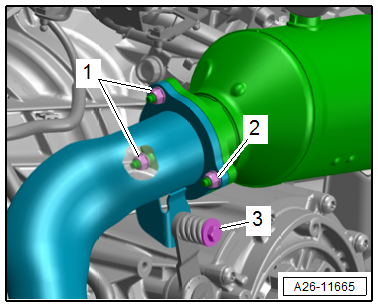

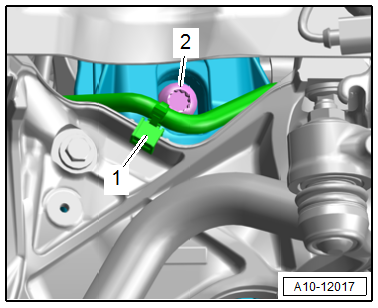

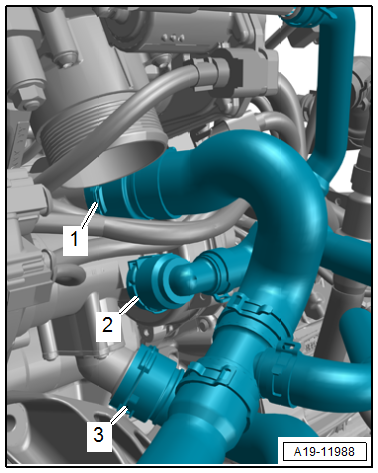

- Equipment version: Disconnect the connector -2- for the Intake Air Switch-Over Valve -N335- and remove the water drain -1- downward in the direction of -arrow-.

- Remove the lock carrier cover. Refer to → Body Exterior; Rep. Gr.63; Front Bumper; Attachments, Removing and Installing.

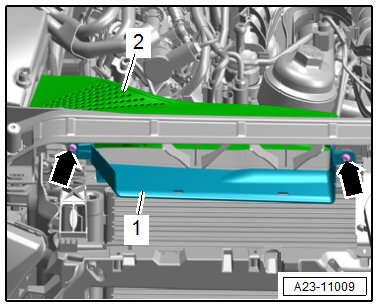

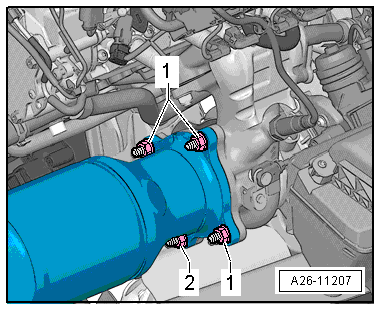

- Remove the bolts -arrows- and the air guide -2-.

Note

Note

Ignore item -1-.

- Disconnect the connector -2- for the Mass Airflow Sensor -G70-.

- Remove the vacuum hose -3-.

- Loosen the hose clamp -4- and remove the air duct hose.

- Pull the air filter housing -1- upward.

- Seal the turbocharger with thoroughly cleaned plugs from the -VAS6122-.

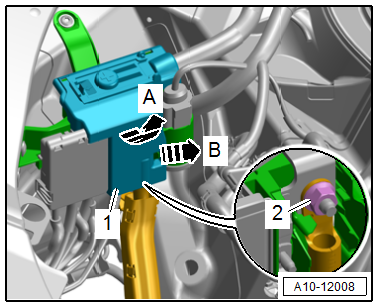

- Release the latch in the direction of -arrow B- and open the E-box -1- in the direction of -arrow A-.

- Remove the nut -2- and free up the B+ wire.

- Free up the upper wiring duct.

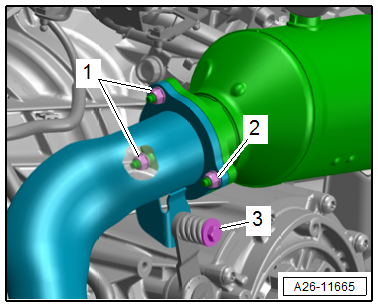

- Remove the nuts -1- from the front muffler accessible from the top.

Note

Note

The nut -2- and bolt -3- will be removed later.

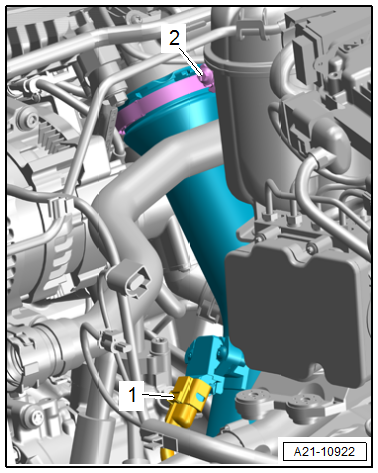

- Disconnect the connector -1- for the Charge Air Pressure Sensor -G31-.

- Loosen the screw-type clamp -2- and remove the air duct pipe from the Throttle Valve Control Module -J338-.

- Place the container of the -VAS5014- or the -VAS6208- underneath.

- Open the drain plug -1- on the connection and drain the coolant.

Note

Note

Ignore item -2-.

- Loosen the left front wheel housing liner in the front area and push slightly toward the rear. Refer to → Body Exterior; Rep. Gr.66; Wheel Housing Liner; Overview - Front Wheel Housing Liner.

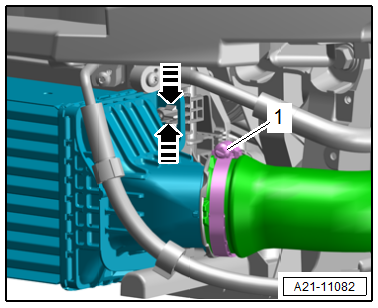

- Loosen the hose clamp -1- and remove the air duct hose and remove downward.

Note

Note

Ignore the -arrows-.

Note

Note

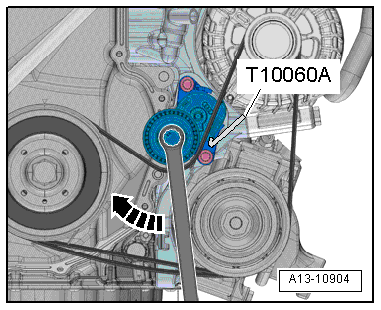

- Risk of destroying by reversing the running direction on a used ribbed belt.

- Before removing the ribbed belt, mark the running direction with chalk or a felt-tip pen for reinstallation.

- Turn the tensioner in the direction of -arrow- to release the tension on the ribbed belt.

- Secure the tensioner using the -T10060A-.

- Remove the ribbed belt.

- Remove the A/C compressor from the bracket. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; A/C Compressor; A/C Compressor, Removing and Installing from Bracket.

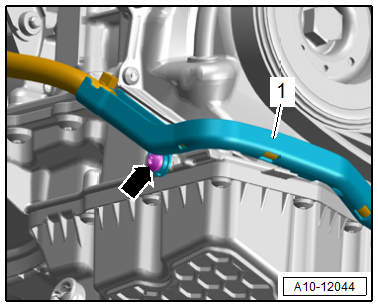

- Remove the bolt -arrow- and remove the wiring duct -1- from the oil pan upper section toward the front and push it downward.

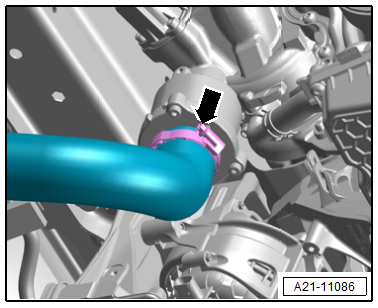

- Loosen the hose clamp -arrow- and remove the air duct hose at the right from the turbocharger.

- Remove the connector -2- from the bracket and disconnect it.

- Release the catches -arrows- and free up the wiring duct -1-.

- Free up the wiring harness to the engine.

- Remove the nut -arrow- and free up the ground wire.

- Remove the bolts -arrows- and remove the right drive axle heat shield.

- Remove the left and right drive axles from the transmission. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Driveshaft; Driveshaft, Removing and Installing.

- Remove the nut -2- and bolt -3- for the front muffler.

Note

Note

Item -1- not already removed.

Caution

Caution

Risk of damaging the couplings in the front muffler.

Do not bend couplings in front muffler more than 10º.

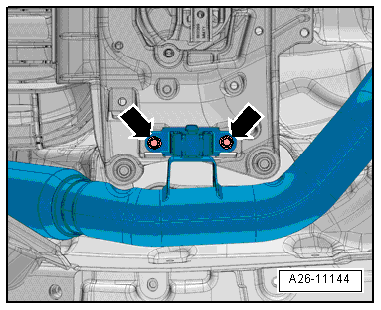

- Remove the bolts -arrows-.

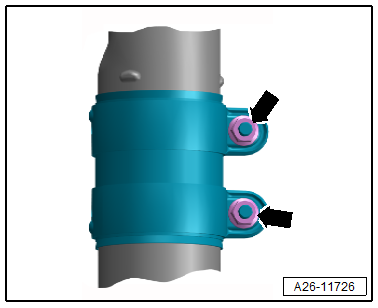

- Loosen the clamping sleeve -arrows- and push toward the rear.

- Remove the front muffler.

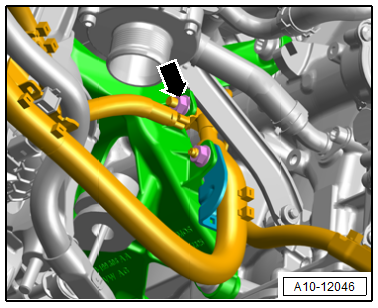

- Remove the catalytic converter nut -2-.

Note

Note

The nuts -1- will be removed later.

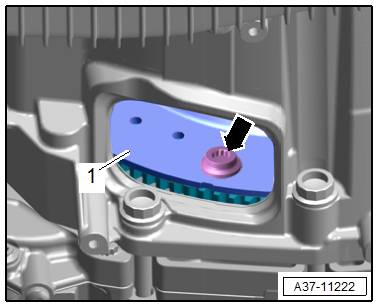

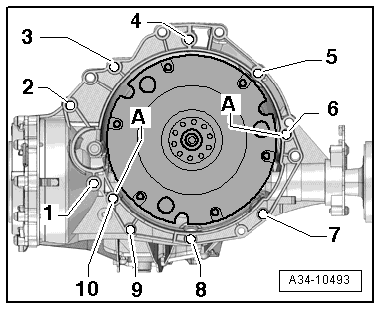

- Remove the lower cover -1- from the transmission in the direction of -arrow-.

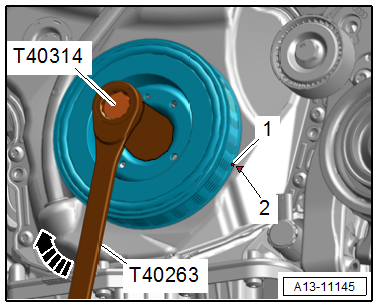

- To loosen the bolts for the flywheel, counterhold the crankshaft using the -T40263- and -T40314-.

Caution

Caution

Risk of destroying the engine by skipping the camshaft timing chain.

Only turn the crankshaft in the direction of engine rotation.

- Turn the crankshaft an additional 120º respectively in the direction of engine rotation in the direction of -arrow-.

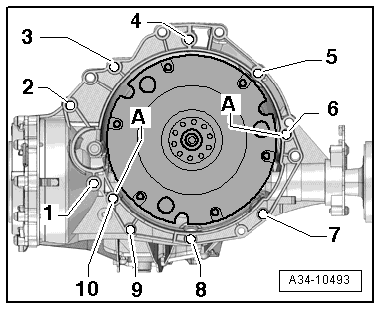

- Remove the three bolts -arrow- for the flywheel -1-.

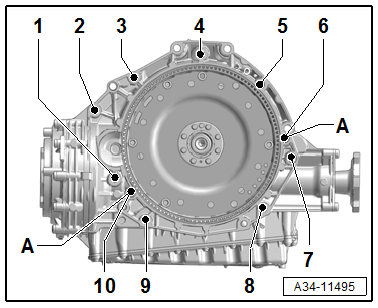

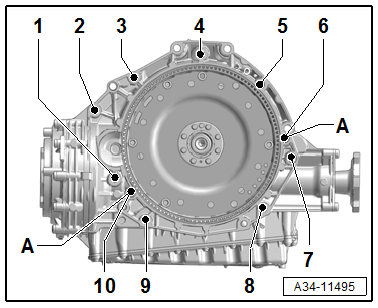

Vehicle with Manual Transmission

- Loosen the bolt -1- with the -VAG1332/14- and -VAS6948-.

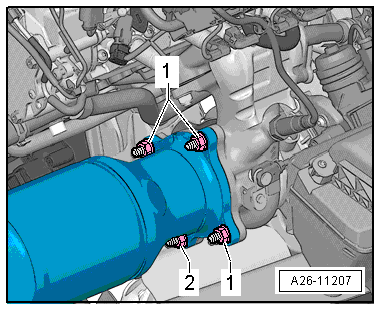

- Remove the bolts -6 through 10- that attach the engine to the transmission.

Vehicle with S tronic Transmission

- Loosen the bolt -1- with the - VAG1332/14- and -VAS6948-.

- Remove the bolts -6 through 10- that attach the engine to the transmission.

Continuation for All Vehicles

- Remove the left and right bolt -2- from the engine mount.

Note

Note

Ignore item -1-.

- Disconnect the connector -1- on the Oxygen Sensor After Catalytic Converter -G130--2- and free up the wires. (There are different installation positions.)

- Remove the connector -1- from the bracket and disconnect it.

- Remove the Heated Oxygen Sensor -G39--2- using a tool from the -3337-.

- Remove the nuts -1- and the catalytic converter upward.

Note

Note

Pay attention to the guidelines for clean working conditions. Refer to → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.00; Repair Information; Guidelines for Clean Working Conditions.

WARNING

WARNING

The fuel system is under pressure.

Risk of injury from fuel spraying out.

- Wear protective eyewear.

- Wear safety gloves.

- Reduce the pressure: Place clean cloths around the connection point and carefully open the connection point.

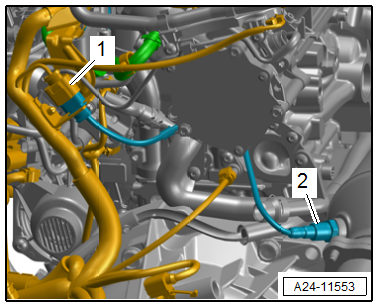

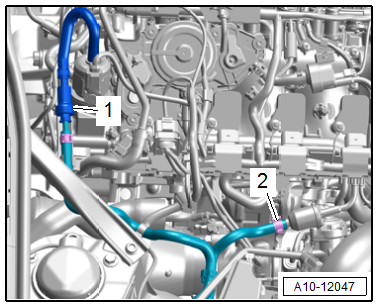

- Remove the fuel hose -1-. Refer to → Fuel Supply System; Rep. Gr.20; Connector Couplings; Connector Couplings, Disconnecting.

- Loosen the hose clamps to disconnect the hose for the EVAP system -2-.

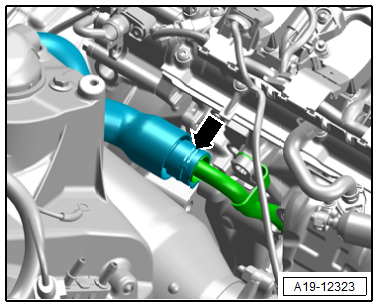

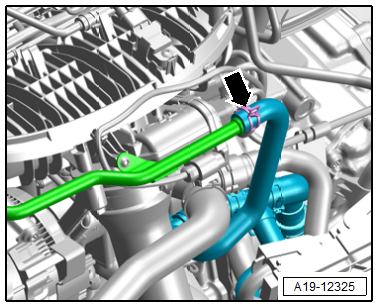

- Lift the clamp -arrow- and remove the coolant hose.

- Lift up the clamps -arrows- and remove and free up the coolant hoses.

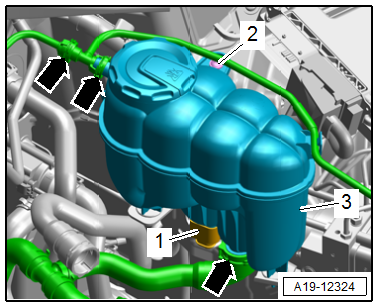

- Disconnect the connector -1- for the Engine Coolant Level Warning Switch -F66-.

- Remove the bolt -2- and remove the coolant expansion tank -3-.

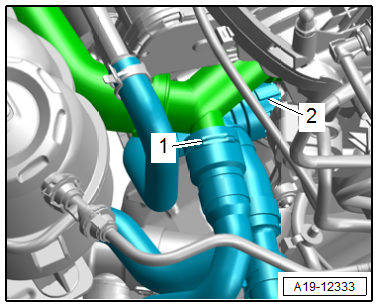

- Lift the clamp -1 and 3-, and remove the coolant hoses.

Vehicle with Dual-Clutch Transmission

- Lift the clamp -2- and remove the coolant hose.

- Loosen the hose clamp -arrow- on the left coolant pipe and remove the coolant hose.

Vehicle with Manual Transmission

- Lift the clamp -1- and remove the coolant hose.

Note

Note

Ignore item -2-.

Continuation for All Vehicles

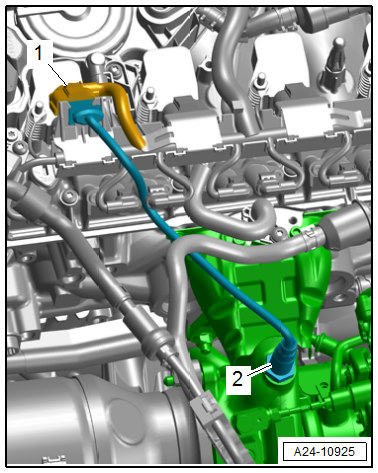

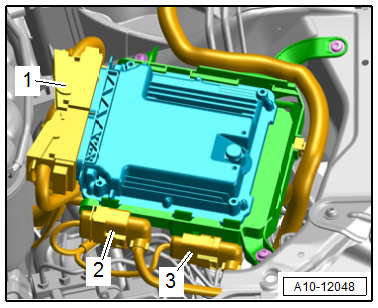

- Remove the connector -2- from the bracket and disconnect it.

- Disconnect the connector -1- from the engine control module.

- Free up the wiring harness and place it on the engine.

- Release the retainer in the direction of -arrow- and remove the vacuum hose -1-.

Vehicle with Manual Transmission

- Remove -2 to 5- that are accessible from above that connect the engine to the transmission.

- Remove the starter slightly from the transmission and leave it in the installation position.

Vehicle with Dual-Clutch Transmission

- Remove the bolts -2 to 5- that are accessible from above that connect the engine to the transmission.

Continuation for All Vehicles

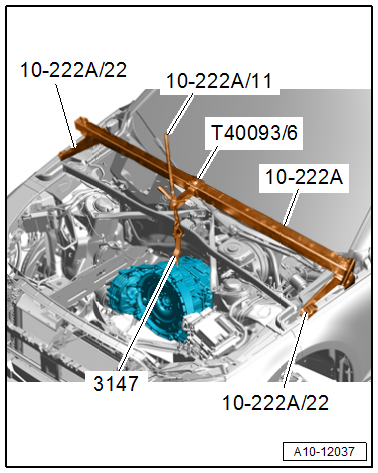

- Position the -10-222A- with -10-222A/22- as shown on the left and right on the fender bolting edge.

- Connect the transmission and the -10-222A/11- with the -3147-.

- Slightly pre-tension the transmission using the spindle.

Note

Note

For clarity, the removed engine is shown.

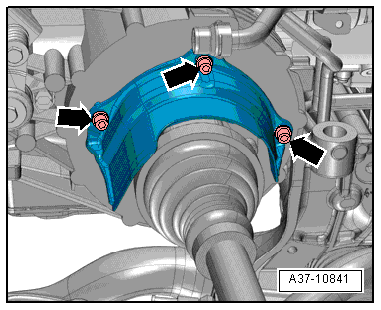

- Engage the -2024A- on the engine and on the -VAS6100- as shown.

WARNING

WARNING

There is the risk of an accident.

Lifting hooks and pins on the engine sling must be secured with securing pins -arrows-.

- Lift the engine until the engine mount is free.

- Turn the -10-222A/11-.

Caution

Caution

Risk of damaging the hose and line connections as well as the engine compartment.

- Make sure all the hose and line connections between the engine, transmission, subframe and body have been disconnected.

- Carefully lift and guide the engine out of the engine compartment.

- - Remove the engine from the transmission and lift it upward out of the engine compartment.

Engine, Securing to Engine and Transmission Holder

All procedures are described under: → Servicing - 4-Cylinder 2.0L 4V TFSI Engine; Rep. Gr.10; Engine, Removing and Installing; Engine, Securing to Engine and Transmission Holder.