Audi A4: Flywheel, Removing and Installing

Special tools and workshop equipment required

- Puller - Clutch Module -T40176-

- Clutch Disc Shaft Spline Lubricant -G 000 100-

- Sealing Grease. Refer to the Parts Catalog.

Removing

Note

Note

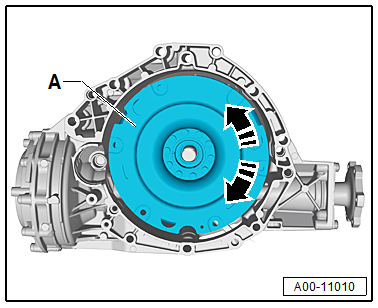

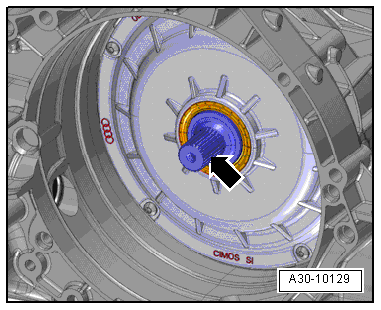

- There is a normal "clicking" in the dual mass flywheel with "LuK" centrifugal pendulum absorber -A-.

- A "clicking" is heard when turning the clutch module -A- approximately every 90º. This noise comes from shifting pendulum masses (centrifugal pendulum absorber) in the dual mass flywheel and is not a fault.

- Secure the transmission on the Engine And Transmission Holder -VAS6095-. Refer to → Chapter "Securing on Engine and Transmission Holder".

- Remove the left flange shaft. Refer to → Chapter "Left Flange Shaft, Removing and Installing".

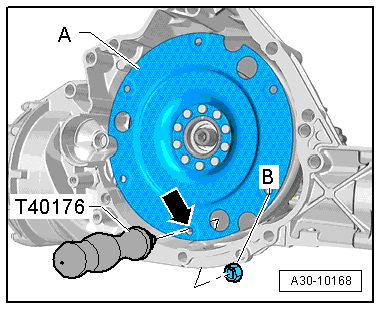

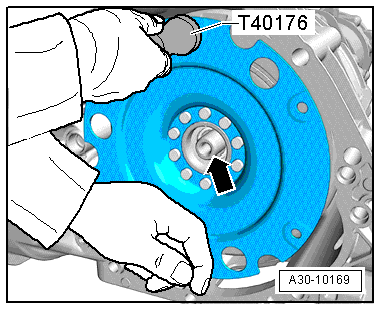

- Attach the Puller - Clutch Module -T40176- to the flywheel -A- with the nut -B--arrow-.

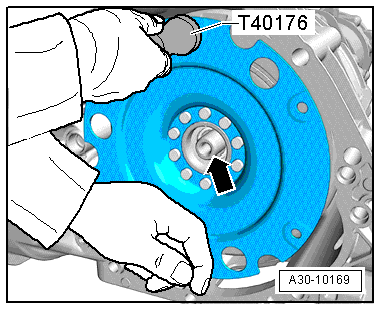

- Turn the Puller - Clutch Module -T40176- upward.

Note

Note

To prevent the flywheel from tilting, counterhold it underneath as shown.

- Remove the flywheel from the input shaft -arrow-. Do not tilt the flywheel when doing this.

Installing

Install in reverse order of removal. At the same time note the following:

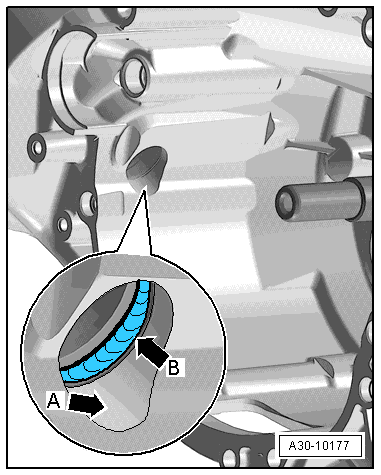

- Always clean the transmission housing in the area where the differential is accessed -arrow A- and the shaft seal -arrow B-.

Note

Note

Replace the shaft seal between the differential and transmission housing -arrow B- if it is damaged.

- Fill the space between the sealing/dust lip halfway with sealing grease. Refer to the Parts Catalog for the correct sealing grease.

- Clean the input shaft -arrow-.

- Lubricate the input shaft splines using Grease for Clutch Disc Shaft Splines -G 000 100-.

- Slide the clutch module onto the input shaft -arrow- carefully without tilting it.

- Remove the Puller - Clutch Module -T40176- from the flywheel -A-.

- Install the left flange shaft. Refer to → Chapter "Left Flange Shaft, Removing and Installing".