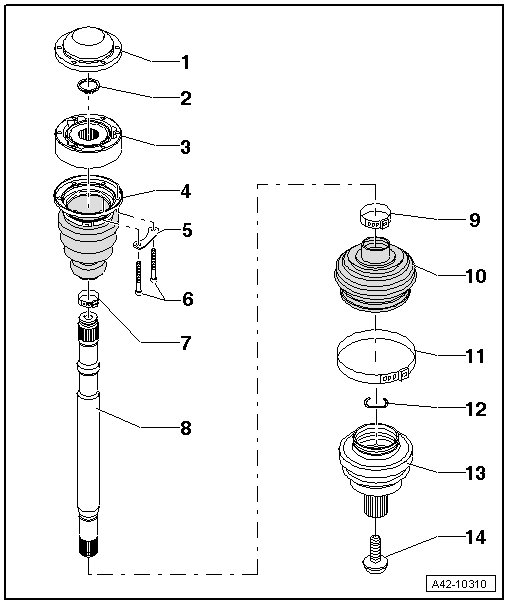

Audi A4: Overview - Drive Axle

Audi A4 (B9) 2016-2026 Service Manual / Chassis / Rear Suspension / Drive Axle / Overview - Drive Axle

1 - Cap

- Carefully drive off using a drift

- Replace if damaged

- Adhesive surface must be free of oil and grease

- Coat the sealing surface with Sealant -D 454 300 A2- before installing on CV joint.

2 - Circlip

- Replace after removing

- Insert in shaft groove

3 - Inner CV Joint

- Only replace completely

- Checking using the Vehicle Diagnostic Tester. Refer to → Chapter "Inner CV Joint, Checking".

- Grease quantity and type.

- The adhesive surfaces must be free of oil and grease.

- When installing the CV joint, thinly coat the profile shaft splines with the grease used in the joint.

4 - CV Boot

- Without vent hole

- Remove the cap carefully using a drift.

- Check for tears and scuffing

- Check the inner CV joint for damage. Refer to → Chapter "Inner CV Joint, Checking".

- The metal cap/CV joint sealing surfaces must be free of grease when installing.

5 - Backing Plate

6 - Bolts

- M8: 30 Nm +90º

- M10: 50 Nm + 90º

- Replace after removing

7 - Clamp

- Replace after removing

- Tensioning. Refer to → Fig. "Tension the Clamp using the Clamping Pliers -VAG1682A-".

8 - Drive Axle

- Removing and installing. Refer to → Chapter "Drive Axle, Removing and Installing".

9 - Clamp

- Replace after removing

- Tensioning.

10 - CV Boot

- Without vent hole

- Check for tears and scuffing

- Check the outer CV joint for damage. Refer to → Chapter "Outer CV Joint, Checking".

- The outer CV boot/metal cap sealing surfaces must be free of grease when installing

- The CV boot/drive axle sealing surfaces must be free of grease when installing

11 - Clamp

- Replace after removing

- Tensioning. Refer to → Fig. "Tension the Clamp using the Clamping Pliers -VAG1682A-".

12 - Circlip

- Replace after removing

- Insert into ring groove of shaft before installation (not visible on installed joint)

- Before installing the CV joint, align the circlip centered to the opening facing upward.

13 - Outer CV Joint

- Only replace completely

- Checking using the Vehicle Diagnostic Tester. Refer to → Chapter "Outer CV Joint, Checking".

- Removing. Refer to → Chapter "Drive Axle, Disassembling and Assembling, Outer CV Joint".

- Installing: Drive onto shaft with a plastic mallet until compressed circlip rebounds.

- Circlip must lie in joint chamfer when guiding in, guide with pliers if necessary.

- Grease quantity and type.

- The CV boot/outer CV joint sealing surfaces must be free of grease when installing.

- When installing the CV joint, thinly coat the profile shaft splines with the grease used in the joint.

14 - Bolt

- Replace after removing

- Clean the threads in the CV joint with a thread tap.

- Drive axle threaded connection, loosening and tightening. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

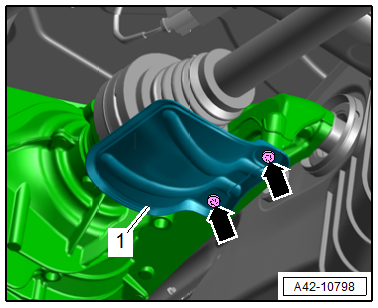

Heat Shield - Tightening Specification

- Tighten the heat shield bolts to 23 Nm.

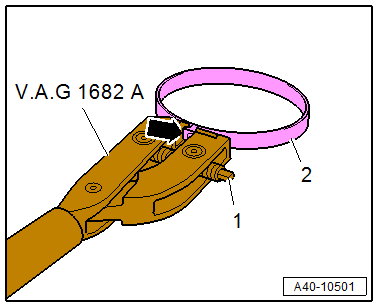

Tension the Clamp using the Clamping Pliers -VAG1682A-.

- Attach the Clamping Pliers -VAG1682- as shown.

- The jaws on the pliers must be centered -arrow- on the clamp -2-.

Note

Note

- The spindle threads must turn easily. If necessary, coat with MoS2 lubricating grease.

- If difficult to tighten, for example because of dirty threads, the proper clamping force of the clamping sleeve will not be reached even when tightened to the specification.

- Tension the clamp by turning the spindle -1- with the torque wrench. Do not tilt the clamping pliers during this.

- Tightening specification: 20 Nm.

Grease Quantity and Type

Note

Note

- Grease the joint again when replacing the CV boot.

- Pay attention to the grease type for the outer and inner joint. Refer to the Parts Catalog.

.png)

1) Apply grease through the ball races.

READ NEXT:

Drive Axle, Removing and Installing

Drive Axle, Removing and Installing

Caution

This procedure contains mandatory replaceable parts.

Refer to component overview and parts catalog prior to

starting procedure.

Mandatory Replacement Parts

Bolt - Outer CV Joint t

Drive Axle, Disassembling and Assembling

Drive Axle, Disassembling and Assembling

Drive Axle, Disassembling and Assembling, Outer CV Joint

Special tools and workshop equipment required

Locking ring pliers, commercially available

Sealant -D454 300 A2-. Refer to the Parts Catalog.

Inner CV Joint, Checking

Inner CV Joint, Checking

It is necessary to disassemble the joint whenever replacing

the grease or if the ball surfaces show wear or damage.

Disassembling

Note

Ball hub and joint are paired and should be identified

SEE MORE:

Extra Equipment

Extra Equipment

Overview - Screen Separator

1 - Screen Separator Mount Trim

Clip into the rear seat backrest

2 - Rubber Grommet

For the screen separator bracket

Slide over the bracket and insert into the trim panel

3 - Screw

4.5 Nm

3 each

4 - Screen Separator Brac

Rearview Camera System, Calibrating

Rearview Camera System, Calibrating

Calibration Unit -VAS6350A-, Installing and Aligning

After performing repair work on the vehicle, it may be

necessary to re-calibrate the rearview camera system. In detail,

this is the case after:

Rearview Camera -R189- removal and installation

Collision repairs on rear lid

Changes to the axle

© 2019-2026 Copyright www.audia4b9.com