Audi A4: Overview - Wheel Bearing

Audi A4 (B9) 2016-2026 Service Manual / Chassis / Rear Suspension / Wheel Bearing and Trailing Arm / Overview - Wheel Bearing

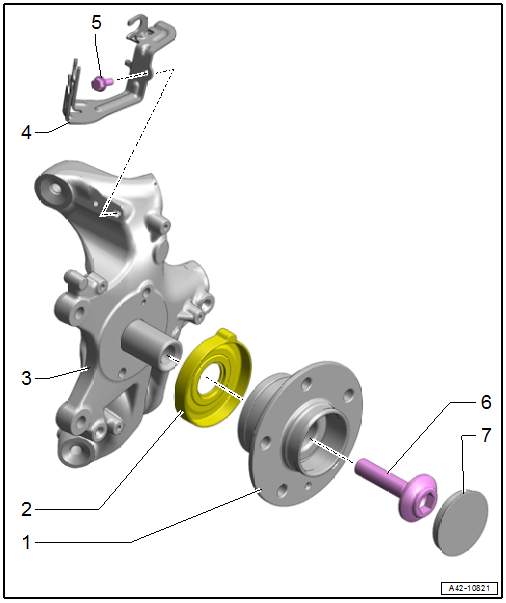

Overview - Wheel Bearing, FWD

1 - Wheel Bearing Unit

- Removing and installing. Refer to → Chapter "Wheel Bearing Unit, Removing and Installing, FWD".

- Handling the wheel bearing. Refer to → Fig. "Wheel Bearing, Handling".

2 - Front Seal

3 - Wheel Bearing Housing

- Removing and installing. Refer to → Chapter "Wheel Bearing Housing, Removing and Installing".

4 - Bracket

- For wires

5 - Bolt

- 8 Nm

- Thread forming

- Position the bolt by hand and tighten it until it finds the old threads. Then tighten the bolt to the specification.

6 - Bolt

- 200 Nm + 180º

7 - Dust Cap

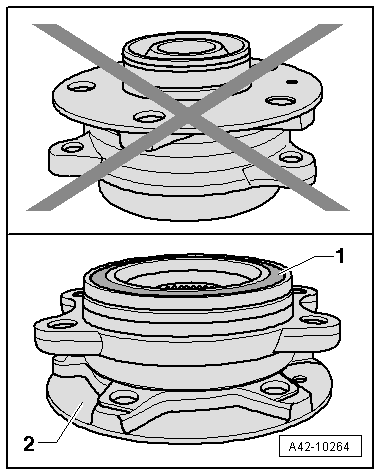

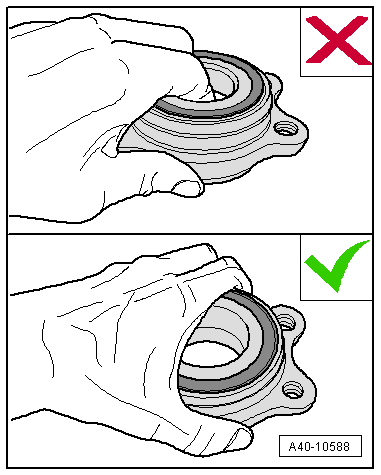

Wheel Bearing, Handling

Caution

Caution

There is a risk of contaminating and damaging the seal.

- The wheel bearing -1- must face up in order to remove the wheel bearing unit.

- Always set the wheel bearing unit down on the wheel hub -2-.

- Never reach inside when lifting the wheel bearing.

- Hold the wheel bearing only on the outside.

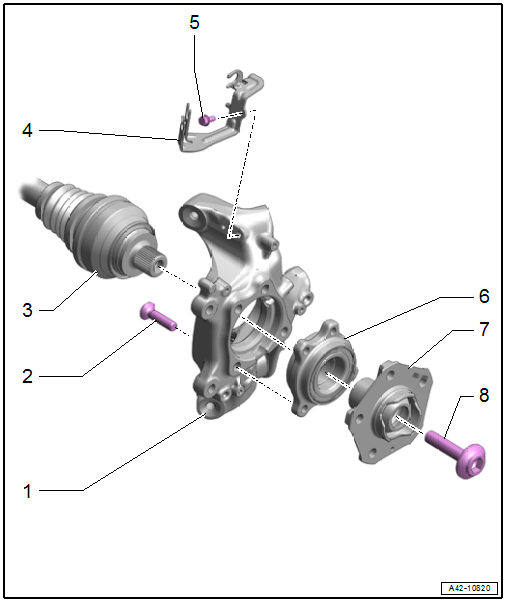

Overview - Wheel Bearing, AWD

1 - Wheel Bearing Housing

- Removing and installing. Refer to → Chapter "Wheel Bearing Housing, Removing and Installing".

2 - Bolt

- 80 Nm + 90º

- Replace after removing

3 - Drive Axle

4 - Bracket

- For wires

5 - Bolt

- 13 Nm

- Thread forming

- Position the bolt by hand and tighten it until it finds the old threads. Then tighten the bolt to the specification.

6 - Wheel Bearing

- Wheel bearing unit, removing and installing. Refer to → Chapter "Wheel Bearing Unit, Removing and Installing".

- Currently only delivered with -7-

- Wheel bearing unit, servicing. Refer to → Chapter "Wheel Bearing Unit, Servicing".

- Handling the wheel bearing. Refer to → Fig. "Wheel Bearing, Handling".

7 - Wheel Hub

- Currently only delivered with -6-

8 - Bolt

- Drive axle threaded connection, loosening and tightening. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

READ NEXT:

Wheel Bearing Housing, Removing and Installing

Wheel Bearing Housing, Removing and Installing

Special tools and workshop equipment required

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

Caution

Thi

Wheel Bearing Unit, Removing and Installing

Wheel Bearing Unit, Removing and Installing

Wheel Bearing Unit, Removing and Installing, FWD

Special tools and workshop equipment required

Puller - Grease Cap -VW637/2-

Camshaft Installer Kit - Sleeve -3241/4- from the Seal

Installer - Cams

Wheel Bearing Unit, Servicing

Wheel Bearing Unit, Servicing

Note

The wheel bearing and wheel hub are currently only delivered

together. As soon as these components are delivered separately,

the following instructions will apply.

Special tools and wor

SEE MORE:

Drive Axle, Removing and Installing

Drive Axle, Removing and Installing

Special tools and workshop equipment required

Torque Wrench 1332 40-200Nm -VAG1332-

Caution

This procedure contains mandatory replaceable parts.

Refer to component overview and parts catalog prior to

starting procedure.

Mandatory Replacement Parts

Bolts - Joint to Transmission

Circl

Receiver/Dryer or Accumulator and Restrictor, Replacing after Cleaning

Refrigerant Circuit

Receiver/Dryer or Accumulator and Restrictor, Replacing after Cleaning

Refrigerant Circuit

Note

Cleaning the refrigerant circuit means flushing it with

refrigerant R134a. Refer to

→ Chapter "Refrigerant Circuit, Cleaning (Flushing), with

Refrigerant R134a" or blowing through with compressed

air and nitrogen. Refer to

→ Chapter "Refrigerant Circuit, Flushing with

© 2019-2026 Copyright www.audia4b9.com