Audi A4: Wheel Bearing Unit, Removing and Installing

Wheel Bearing Unit, Removing and Installing, FWD

Special tools and workshop equipment required

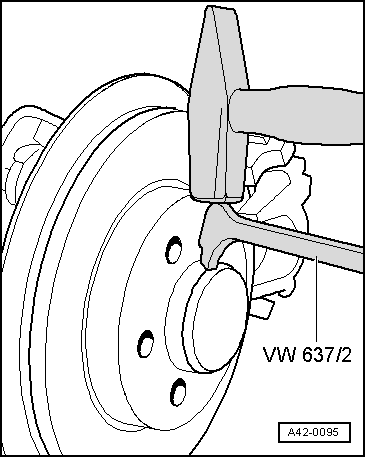

- Puller - Grease Cap -VW637/2-

- Camshaft Installer Kit - Sleeve -3241/4- from the Seal Installer - Camshaft Installer Kit -3241-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Torque Wrench 1410 -VAG1410-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Removing

- Remove the brake rotor. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Rotor, Removing and Installing.

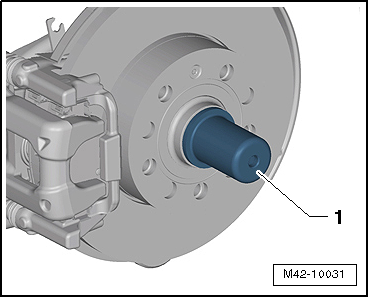

- Loosen the dust cap from the seat by tapping lightly on claw of the -VW637/2- with the hammer.

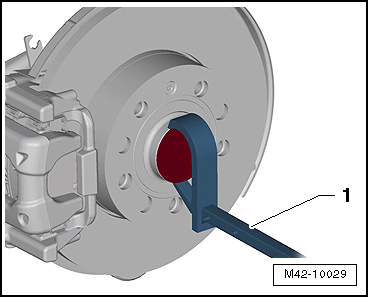

- Press the dust cap off using the -VW637/2--1-.

Caution

Caution

There is a risk of damaging the threads.

The bolt must not be loosened or tightened with an impact wrench.

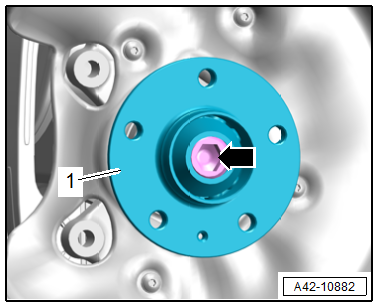

- Remove the bolt -arrow- and remove the wheel bearing unit -1- from the axle stub.

- Handling the wheel bearing. Refer to → Fig. "Wheel Bearing, Handling".

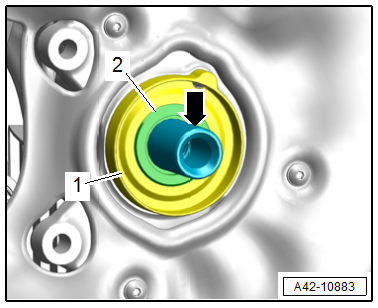

- Remove the metal washer -2- and front seal -1- from the axle stub -arrow-.

Installing

Note

Note

Replace the bolt and dust cap after removal.

- Apply the front seal -1-.

- Lightly lubricate the metal washer -2- and the axle stub -arrow- with grease.

- Carefully slide the wheel bearing unit on the axle stub and do not tilt while doing so.

Further installation is performed in reverse order of removal, while noting the following:

Caution

Caution

There is a risk of premature wear on the wheel bearing.

Use the tools pictured to avoid any moisture entering through a damaged dust cap.

- Drive in the new dust cap all the way using the -3241/4--1-.

Tightening Specifications

- Refer to → Chapter "Overview - Wheel Bearing, FWD"

Wheel Bearing Unit, Removing and Installing, AWD

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- Torque Wrench 1410 -VAG1410-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview and parts catalog prior to starting procedure.

Mandatory Replacement Parts

- Bolt - Wheel Bearing to Wheel Bearing Housing

Removing

- Loosen the connection between the drive axle and wheel hub. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

- Remove the brake rotor. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Rotor, Removing and Installing.

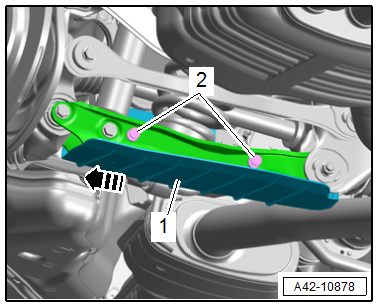

- Remove the expanding rivets -2-.

- Pull the wind deflector -1- slightly outward in the direction of the -arrow- and remove.

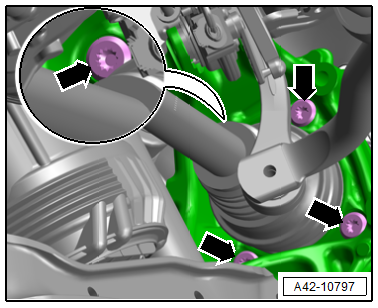

- Remove the bolts -arrows- in stages, and remove the wheel bearing unit from the drive axle and the wheel bearing housing at the same time.

- Handling the wheel bearing. Refer to → Fig. "Wheel Bearing, Handling".

Installing

Install in reverse order of removal and note the following:

- Tighten the threaded connection between the drive axle and wheel hub. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

Tightening Specifications

- Refer to → Chapter "Overview - Wheel Bearing, AWD"