Audi A4: Transmission, Installing

Special tools and workshop equipment required

- Clutch Module Assembly Aid -T40169-

- Clutch Module Transportation Lock -T40170-

- As well as all the special tools listed for the removal.

Procedure

Caution

Caution

Risk of damaging the transmission by mixing ATF and transmission fluid (MTF) through the same bleeder.

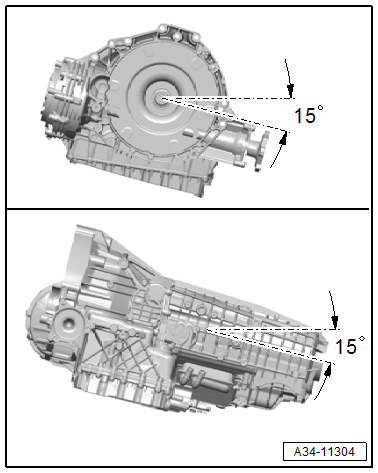

- The transmission filled with ATF and (MTF) transmission fluid must be tilted a maximum of 15Âş in lateral and longitudinal direction.

- If more of an incline is needed, then the ATF and (MTF) transmission fluids must be drained. Refer to → Chapter "ATF, Draining and Filling" and → Chapter "Transmission Fluid, Draining and Filling".

Note

Note

- Replace the bolts that were tightened with an additional turn.

- Replace self-locking nuts and bolts, O-rings, sealing rings and seals.

- Secure hose connections with hose clamps that correspond to the series production. Refer to the Parts Catalog.

- During installation, all cable ties must be installed at the same location.

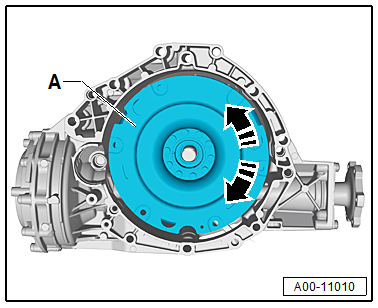

- There is a normal "clicking" in the dual mass flywheel with "LuK" centrifugal pendulum absorber.

- A "clicking" is heard when turning in direction of -arrows- the clutch module -A- approximately every 90Âş. This noise comes from shifting pendulum masses (centrifugal pendulum absorber) in the dual mass flywheel and is not a fault.

Caution

Caution

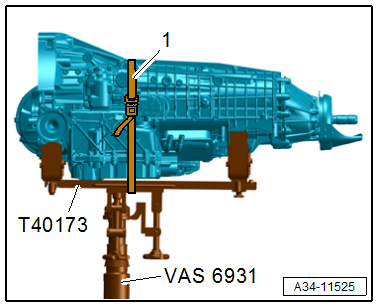

Danger of leaks in the oil pan.

The Gearbox Support -T40173- must not be set on the oil pan.

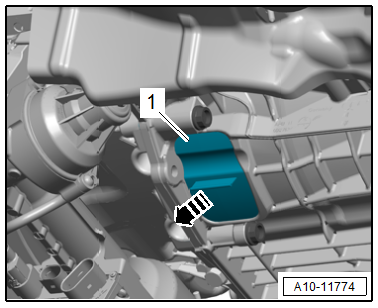

- Mount the transmission onto the Gearbox Support -T40173- and secure it using the tension strap -1- as shown.

- The following preparations must be made before connecting the engine and transmission:

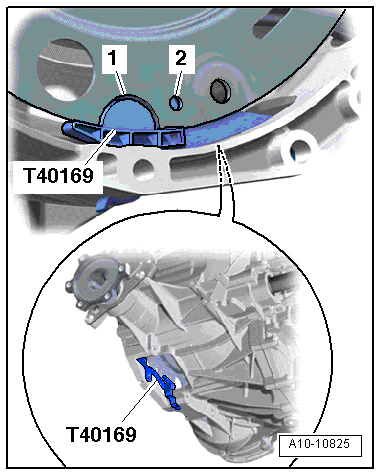

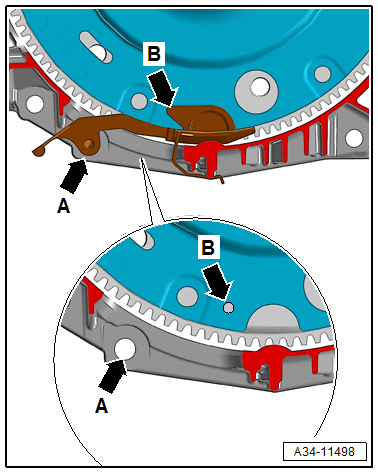

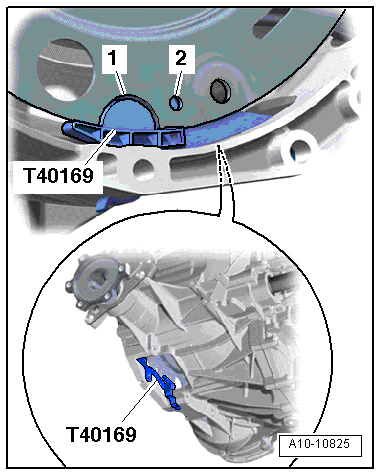

- Insert the Clutch Module Assembly Aid -T40169- in the transmission housing and the flywheel from below as shown.

- The tool must grip into the semicircular hole and also in the hole -arrows A and B-.

Note

Note

There is only one inspection opening -arrow B- on the edge. Rotate the flywheel as needed.

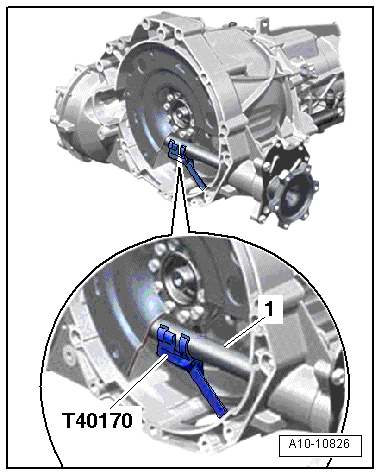

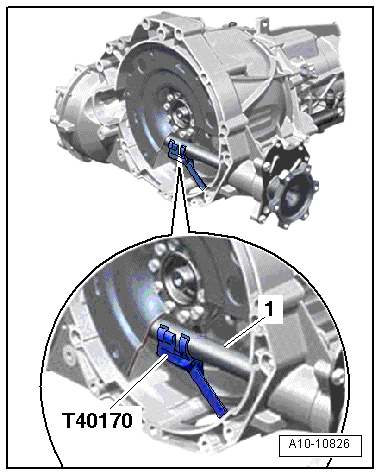

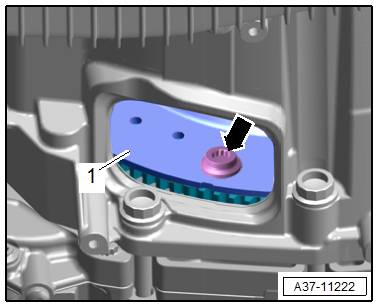

- Insert the Clutch Module Transportation Lock -T40170- in the transmission housing from below and secure it on the flange shaft -1-.

- Inspect the aluminum bolts used to connect the engine to the transmission to see if they can be used again and mark them, if necessary.

Vehicles with Sealing Piece

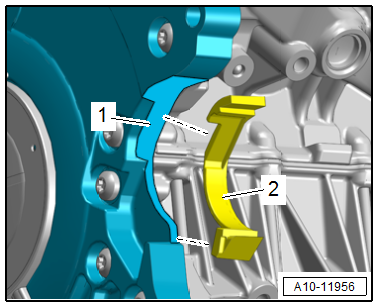

- Clean the contact surface -1- on the lower timing chain cover and on the sealing piece -2- with Cleaning Solution - D 009 401 04-.

- Bond the sealing piece with the lower timing chain cover:

Vehicles with 4-Cylinder Engine

Note

Note

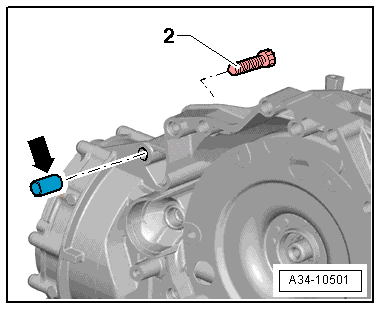

- The bolt -2- attaches the starter to the transmission and has an additional spacer sleeve -arrow-.

- The spacer sleeve must be inserted between the starter and the transmission.

All Vehicles:

- Bring the starter into the installation position.

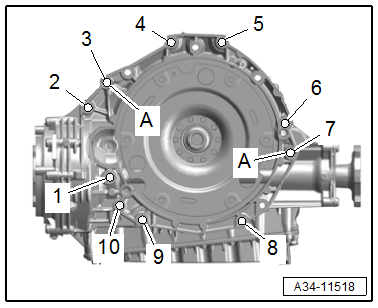

- Check if that the alignment sleeves -A- for centering the engine and transmission are inserted in the cylinder block.

- Place the transmission on the engine to do so guide the starter.

- Tighten the bolt -8- hand-tight.

- Install tunnel crossmember. Refer to → Chapter "Overview - Subframe Mount".

- Remove the extractor. Refer to → Rep. Gr.10; Subframe Mount; Engine in Installation Position, Supporting.

- Tighten the bolts -1 to 10-.

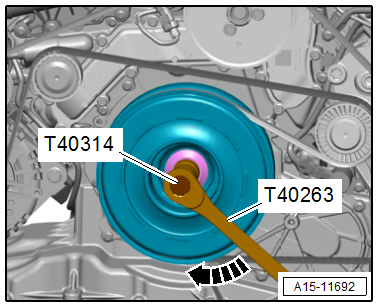

- Turn the crankshaft on the vibration damper 360Âş in the direction of engine rotation -arrow-.

- Remove the Clutch Module Transportation Lock -T40170-.

- Remove the Clutch Module Assembly Aid -T40169-.

Note

Note

Use the Torque Wrench 1331 Insert - Open Jaw - 13mm -VAG1332/14- to tighten the bolts.

- Tighten the flywheel to the drive plate as follows:

Vehicle with 4-Cylinder Engine (Three Bolts):

- Install the first bolt -arrow-, tighten to 10 Nm, loosen and then tighten to 2 Nm (hand-tight).

- Turn the crankshaft on the vibration damper 120Âş in the direction of the engine rotation with a large offset open-end wrench.

- Install the next bolt in this crankshaft stub and tighten. Refer to → Chapter "Transmission Tightening Specifications".

- Turn the crankshaft another 120Âş in the direction of engine rotation and install the next bolt and tighten.

- Turn the crankshaft another 120Âş in the direction of engine rotation and tighten the last bolt.

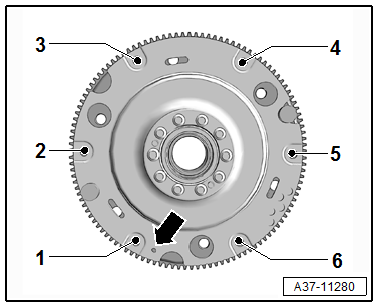

Vehicle with 6-Cylinder Engine (Six Bolts):

- Install the first bolt -1- and tighten to 10 Nm, loosen and then tighten to 2 Nm (hand-tight).

- Turn the crankshaft on the vibration damper 180º in the direction of engine rotation, install bolt -4- and tighten. Refer to → Chapter "Transmission Tightening Specifications".

- Turn the crankshaft another 60Âş in the direction of engine rotation, install bolts -5 and 6- and tighten.

- Turn the crankshaft another 60Âş in the direction of engine rotation and tighten bolt -1-.

- Turn the crankshaft another 60Âş in the direction of engine rotation, install bolts -2 and 3- and tighten.

All Vehicles:

- Install the cover -1-.

Install in reverse order of removal. Note the following:

- Connections and routing. Refer to → Wiring diagrams, Troubleshooting & Component locations.

- Tighten the drive axles. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Drive Axle; Overview - Drive Axle.

- Install the drive axle heat shield. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Drive Axle; Drive Axle Heat Shield, Removing and Installing.

- Install the drive axle cover. Refer to → Body Exterior; Rep. Gr.66; Wheel Housing Liner; Overview - Front Wheel Housing Liner.

- Install the front wheels. Refer to → Suspension, Wheels, Steering; Rep. Gr.44; Wheels, Tires.

- Install the parking lock emergency release cable. Refer to → Chapter "Parking Lock Emergency Release Cable, Removing and Installing".

- Install the coolant pipe for the transmission. Refer to → Engine Mechanical; Rep. Gr.19; Coolant Pipes.

- Install the steering intermediate shaft. Refer to → Suspension, Wheels, Steering; Rep. Gr.48; Steering Column; Steering Intermediate Shaft, Removing and Installing.

- Install the driveshaft. Refer to → Rear Final Drive; Rep. Gr.39; Driveshaft; Driveshaft, Removing and Installing.

- Install the emissions control module. Refer to → Engine, Mechanical; Rep. Gr.26; Emissions Control; Emissions Control Module, Removing and Installing.

- Install the front exhaust pipe. Refer to → Engine, Mechanical; Rep. Gr.26; Exhaust Pipe/Muffler; Front Exhaust Pipe, Removing and Installing.

- Install the subframe crossbrace. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Subframe; Overview - Subframe.

- Fill the coolant. Refer to → Rep. Gr.19; Cooling System/Coolant; Coolant, Draining and Filling.

- Follow all steps after connecting the battery. Refer to → Electrical Equipment; Rep. Gr.27; Battery; Battery, Disconnecting and Connecting.

- Check the ATF level and correct if necessary. Refer to → Chapter "ATF Level, Checking".

Note

Note

If a new factory transmission is installed, an ATF level test is not necessary.

Note

Note

If the transmission is replaced, the "Replace control module" function must be performed. Refer to Vehicle Diagnostic Tester.

Procedure

- Connect the Vehicle Diagnostic Tester.

- Select Diagnostic mode and start the diagnostic.

- Select the Test plan tab.

- Select individual test button and select the following tree structure one after the other:

- Drivetrain

- 7-Speed Dual Clutch Transmission 0CJ, 0CK, 0CL

- 01 - OBD-capable systems

- 02 - Transmission electronics 0CK

- 02 - Transmission electronics, functions

- 02 - Replace control module ⇒ Entire transmission

- Start the selected program and follow the instructions in the display of the Vehicle Diagnostic Tester.