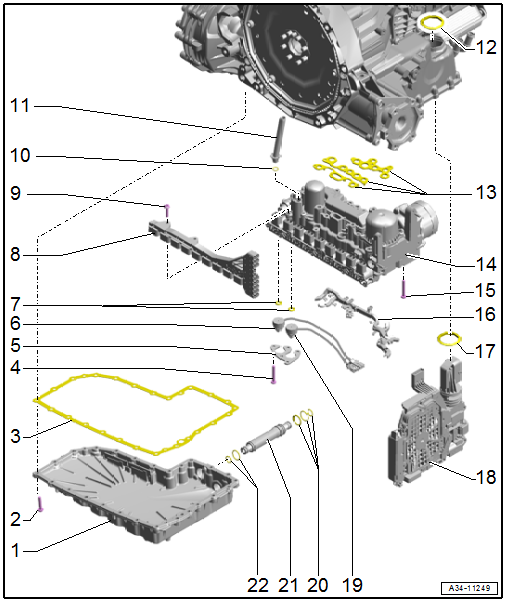

Audi A4: Mechatronic

Overview - Mechatronic

1 - Transmission Fluid Pan

- Removing and installing. Refer to → Chapter "Transmission Fluid Pan, Removing and Installing".

- Aluminum or plastic

2 - Bolt

- Tightening specification and sequence. Refer to → Fig. "Transmission Fluid Pan - Tightening Specification and Sequence".

3 - Seal

- Replace after removing

4 - Bolt

- Tightening specification. Refer to → Servicing - 7-Speed Dual Clutch Transmission 0CJ, 0CK, 0CL; Rep. Gr.34; Mechatronic; Overview - Mechatronic.

5 - Bracket

6 - Hydraulic Pressure Sensor 2 -G546-

- Removing and installing. Refer to → Servicing - 7-Speed Dual Clutch Transmission 0CJ, 0CK, 0CL; Rep. Gr.34; Mechatronic; Overview - Mechatronic.

7 - O-Rings

- Replace after removing

8 - Contact Element

9 - Bolt

- Tightening specification. Refer to → Servicing - 7-Speed Dual Clutch Transmission 0CJ, 0CK, 0CL; Rep. Gr.34; Mechatronic; Overview - Mechatronic.

10 - O-Ring

- Replace after removing

11 - Bleed Pipe

12 - Dust Ring

13 - Seals

- Replace after removing

14 - Mechatronic

- Removing and installing. Refer to → Chapter "Mechatronic, Removing and Installing".

15 - Mechatronic Bolt. Refer to → Servicing - 7-Speed Dual Clutch Transmission 0CJ, 0CK, 0CL; Rep. Gr.34; Mechatronic; Overview - Mechatronic.

16 - Wiring Guide

17 - Seal

- Replace after removing

18 - Transmission Control Module -J217-

- Removing and installing. Refer to → Servicing - 7-Speed Dual Clutch Transmission 0CJ, 0CK, 0CL; Rep. Gr.34; Mechatronic; Overview - Mechatronic.

19 - Hydraulic Pressure Sensor 1 -G545-

- Removing and installing. Refer to → Servicing - 7-Speed Dual Clutch Transmission 0CJ, 0CK, 0CL; Rep. Gr.34; Mechatronic; Overview - Mechatronic.

20 - O-Rings

- Replace after removing

21 - ATF Pipe

- Replace after removing

22 - Seals

- Replace after removing

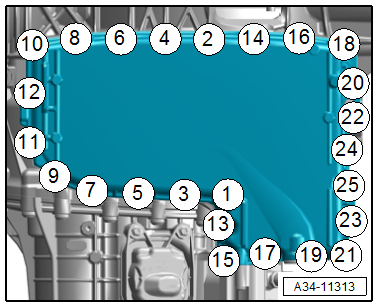

Transmission Fluid Pan - Tightening Specification and Sequence

- Tighten the bolts in steps according to the specified sequence:

.png)

Transmission Fluid Pan, Removing and Installing

Special tools and workshop equipment required

- Vehicle Diagnostic Tester

- Engine Bung Set -VAS6122-

- Used Oil Collection and Extraction Unit -SMN372500-

Removing

Caution

Caution

Risk of damaging the transmission.

Do not run engine or tow vehicle when the transmission fluid pan is removed or without transmission fluid.

WARNING

WARNING

The system is under pressure.

Deactivate the ATF pump and drain the hydraulic pressure reservoir before removing the transmission fluid pan!

- Using the Vehicle Diagnostic Tester in the Transmission Control Module -J217- empty the ATF pressure reservoir and disable the Transmission Fluid Auxiliary Hydraulic Pump -V552-. Refer to → Chapter "ATF Pump, Deactivating and Draining the Hydraulic Pump Reservoir".

- Remove the ATF cooler. Refer to → Chapter "ATF Cooler, Removing and Installing".

- Remove the subframe crossbrace. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Subframe; Subframe Crossbrace, Removing and Installing.

- Remove the bolts in the sequence -25 to 1- and remove the transmission fluid pan.

Installing

Install in the reverse order of removal while noting the following:

Note

Note

Replace the seal and ATF pipe after removal.

- Install the ATF cooler. Refer to → Chapter "ATF Cooler, Removing and Installing".

Tightening Specifications

- Refer to → Fig. "Transmission Fluid Pan - Tightening Specification and Sequence"

- Refer to → Suspension, Wheels Steering; Rep. Gr.40; Subframe; Overview - Subframe.

Mechatronic, Removing and Installing

Special tools and workshop equipment required

- Vehicle Diagnostic Tester

Removing

WARNING

WARNING

The system is under pressure.

Deactivate the ATF pump and drain the hydraulic pressure reservoir before removing the transmission fluid pan!

- Using the Vehicle Diagnostic Tester in the Transmission Control Module -J217- empty the ATF pressure reservoir and disable the Transmission Fluid Auxiliary Hydraulic Pump -V552-. Refer to → Chapter "ATF Pump, Deactivating and Draining the Hydraulic Pump Reservoir".

- Remove the subframe crossbrace. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Subframe; Subframe Crossbrace, Removing and Installing.

- Remove the transmission fluid pan. → Chapter "Transmission Fluid Pan, Removing and Installing".

Refer to → Servicing - 7-Speed Dual Clutch Transmission 0CJ, 0CL, 0CK; Rep. Gr.34; Mechatronic; Mechatronic, Removing and Installing for all further work on the Mechatronic.

Installing

Install in reverse order of removal.

Tightening Specifications

- Refer to → Chapter "Overview - Mechatronic"

- Refer to → Suspension, Wheels Steering; Rep. Gr.40; Subframe; Overview - Subframe.